Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 57

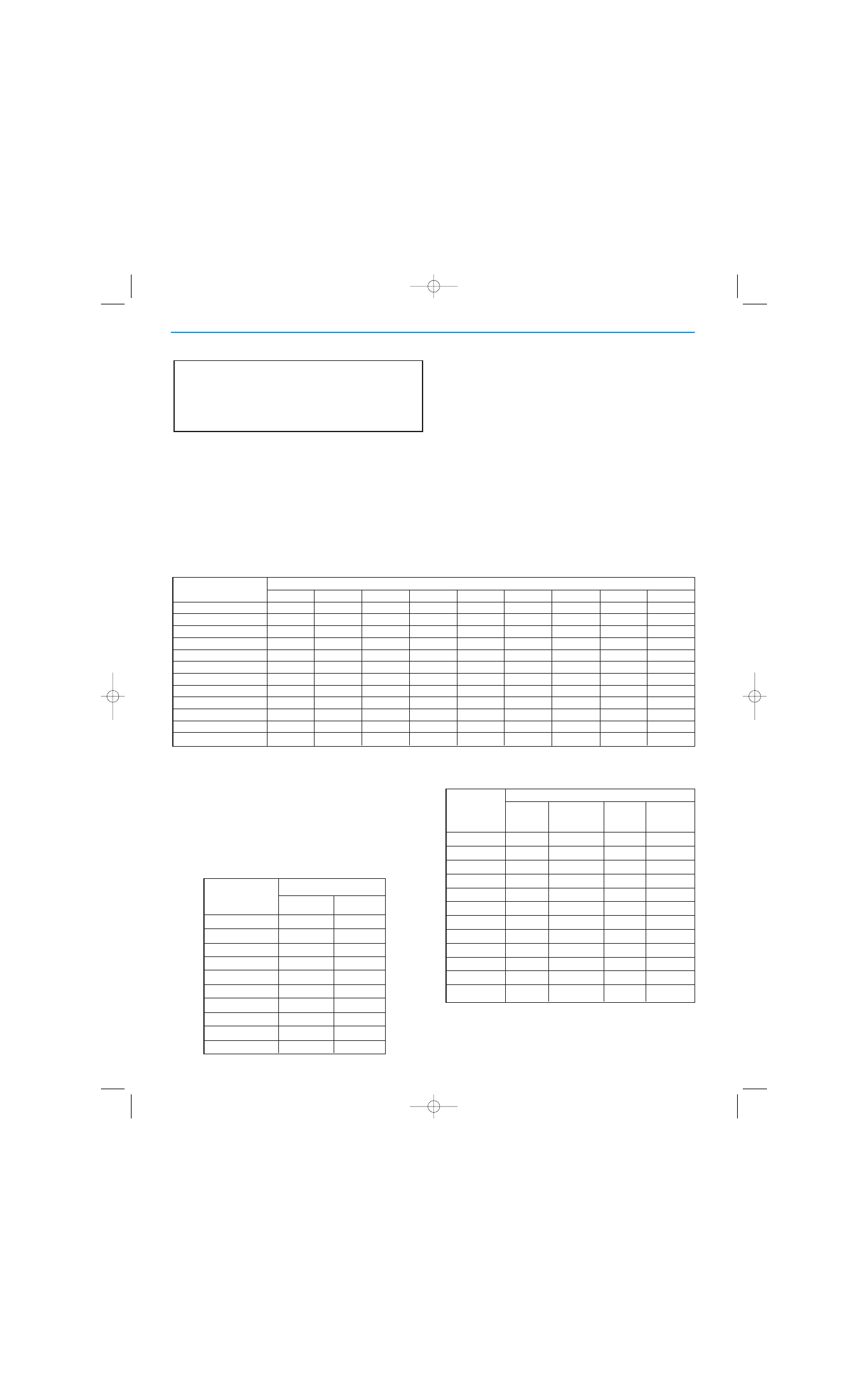

GREASE LUBRICATION

DODGE IP and ISAF Unitized Spherical roller bearings

are prepacked with a NLGI #2 lithium 12-Hydroxy-

stearate grease. For relubrication select a grease that is

compatible with #2 lithium 12-Hydroxystearate.

Relubricate in accordance with the recommendation of

Table 2.

MAINTENANCE

WARNING

To ensure that drive is not unexpectedly started,

turn off and lock-out or tag power source before

proceeding. Failure to observe these precautions

could result in bodily injury.

EXPANSION BEARING

Total Expansion (in.)

Bore Size

IP

ISAF

1

1

/

8

- 1

1

/

2

3

/

16

7

/

32

1

5

/

8

- 1

7

/

8

1

/

4

7

/

32

1

15

/

16

- 2

1

/

4

17

/

64

2

13

/

16

1

/

4

7

/

32

2

1

/

4

- 2

7

/

16

1

/

4

5

/

16

2

1

/

2

- 3

3

/

16

1

/

4

15

/

64

3

1

/

4

- 3

1

/

2

1

/

4

3

/

8

3

11

/

16

- 4

5

/

16

3

/

8

4

7

/

16

- 5

3

/

8

3

/

8

5

7

/

16

- 7

N/A

3

/

8

STORAGE OR SPECIAL SHUT DOWN

If equipment will be idle for some time, before shutting

down, add compatible grease to the bearing until grease

purges from the seals. This will ensure protection of the

bearing, particularly when exposed to severe environ-

mental conditions. After storage or idle period, add fresh

grease to the bearing before starting.

TABLE 3 – Cap Bolt Torque for ISAF Pillow Blocks

(Non-Expansion & Expansion) (Grade 5 Bolts)

2 Bolt Base

4 Bolt Base

Torque

Bore

Bolt

Torque

Bolt

Size (In.)

Size

Ft.-Lbs.

Size

Ft.-Lbs.

1

7

/

16

-1

11

/

16

3

/

8

-16

24-30

–

–

1

15

/

16

-2

3

/

16

7

/

16

-14

40-50

–

–

2

7

/

16

-2

1

/

2

1

/

2

-13

60-75

1

/

2

-13

60-75

2

11

/

16

-3

5

/

8

-11

120-150

5

/

8

-11

120-150

3

7

/

16

-3

1

/

2

3

/

4

-10

208-260

3

/

4

-10

208-260

3

15

/

16

-4

–

–

3

/

4

-10

208-260

4

7

/

16

-4

1

/

2

–

–

7

/

8

-9

344-430

4

15

/

16

-5

–

–

1-8

512-640

5

7

/

16

-5

1

/

2

–

–

1-8

512-640

5

15

/

16

-6

–

–

1-8

512-640

6

7

/

16

-6

1

/

2

–

–

1-8

512-640

6

15

/

16

-7

–

–

1-8

512-640

Table 2

Regreasing Intervals (Months) (Based on 12 hours per day, 150 degrees F. Max)

SHAFT

RPM

SIZE

250

500

750

1000

1250

1500

2000

2500

>3000

1

7

/

16

4

3

2

2

1

0.5

0.25

0.25

0.25

1

11

/

16

4

3

2

2

1

0.5

0.25

0.25

0.25

1

15

/

16

, 2 SM

4

3

2

2

1

0.5

0.25

0.25

0.25

2 LG, 2

3

/

16

3.5

2.5

1.5

1

0.5

0.5

0.25

0.25

0.25

2

3

/

8

, 2

7

/

16

3

2

1.5

1

0.5

0.25

0.25

0.25

—

2

11

/

16

, 2

3

/

4

, 2

15

/

16

3

2

1.5

1

0.5

0.25

0.25

0.25

—

3

7

/

16

2.5

1.5

1

0.5

0.25

0.25

0.25

—

—

3

15

/

16

2

1.5

1

0.5

0.25

0.25

—

—

—

4

7

/

16

2

1.5

1

0.5

0.25

—

—

—

—

4

15

/

16

1.5

1

0.5

0.25

—

—

—

—

—

5

7

/

16 -

5

1

/

2

1.5

1

0.5

0.25

—

—

—

—

—

5

15

/

16 -

7

1

0.5

0.5

0.25

—

—

—

—

—

OPERATION TEMPERATURES

Abnormal bearing temperatures may indicate insufficient

lubrication. If the housing is too hot to touch for more

than a few seconds, check the temperature by applying

a thermometer at the top of the pillow block with the ther-

mometer top surrounded by putty.

Because the thermometer reading will be approximately

10°F lower than the actual bearing temperature, add ten

degrees to the reading and compare to the temperature

rating of your grease. If the bearing temperature reading

is consistent and operating within the recommended lim-

its of your grease, the bearing is operating satisfactorily.

The recommended maximum operating temperature for

No. 2 lithium base grease is 200°F.

6954 Layout 3/1/02 8:50 AM Page 4

52 PNEG-1204 Enclosed Belt Conveyors