Cooling fan installation – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 50

COOLING FAN INSTALLATION

WARNING: To ensure that drive is not unexpectedly started,

turn off and lock out or tag power source before proceeding.

Remove all external loads from drive before removing or

servicing drive or accessories. Failure to observe these

precautions could result in bodily injury.

Unpack all components and inspect for shipping damage. Do

not use any component that has been damaged or modified.

Make sure all components are clean and free of any foreign

material prior to assembly. Cooling fan assembly is designed to

fit onto the input shaft before placement of sheeves or belt

guard assembly.

Installation for TA4207CF and TA5215CF:

1. Referring to Figure 2, install tapered bushing (9) into bore of

fan blade assembly (2) and loosely install the three set screws

provided with fan. Snug set screws but do not tighten at this

time.

2. Slide fan assembly onto input shaft and install input shaft

key. Note: Key is supplied with the TAII reducer. Locate fan

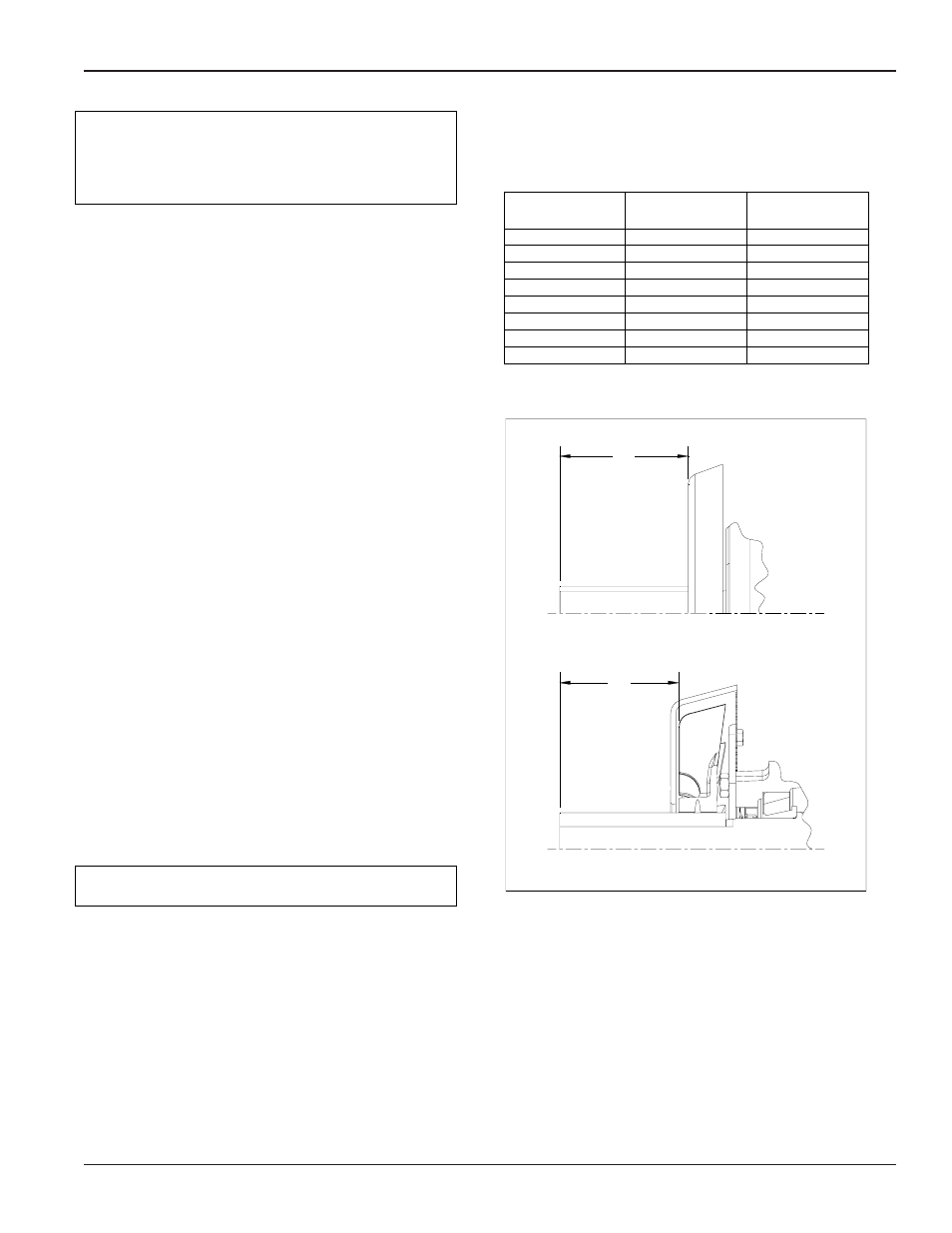

blade edge distance “A” (Figure 1) from end of shaft per Table

1. Make sure fan assembly rotates without interference when

input shaft is rotated.

3. Alternately tighten the set screws until fan assembly is

securely installed on the input shaft.

4. Recheck fan assembly for proper location and clearance.

Loosen set screws and repeat steps 2 and 3 above if not

properly located.

Installation for TA6307CF through TA12608CF:

1. Referring to Figure 2, install fan guard back plate assembly

(1) using the four bolts (4) provided. Note that the screen is

mounted towards the reducer. Tighten to recommended torque

in Table 1.

CAUTION: Fan guard screen has sharp edges. Use caution

when installing to avoid lacerations.

2. Slide fan blade assembly (2) onto input shaft and install key

and set screws (5). Note: Key is supplied with the TAII reducer.

Position fan blade edge distance “A” (Figure 1) from end of shaft

per Table 1. Make sure fan assembly rotates without

interference when input shaft is rotated. Tighten the two fan

blade set screws (5) securely.

3. Install fan guard cover (3) with four bolts (6), lockwashers (7),

and hex nuts (8). Tighten securely.

4. Verify fan blade rotates freely and does not interfere with fan

guard back plate (1) or fan guard cover (3). Adjust fan blade if

necessary.

Table 1 - Dimensions and Bolt Torque

Reducer Size

Dim.”A” mm

Torque (Ft.-Lbs.)

TA4207H

3-3/4

-----

TA5215H

4-5/8

-----

TA6307H

4-1/4

33 - 30

TA7315H

4-3/8

33 - 30

TA8407H

5-1/16

33 - 30

TA9415H

6-1/4

33 - 30

TA10507H

6-7/16

33 - 30

TA12608H

6-7/16

33 - 30

Figure 1 - Fan Blade Placement

A

A

TYPICAL FOR REDUCER SIZES 4 AND 5

TYPICAL FOR REDUCER SIZES 6 THRU 12

45

PNEG-1204 Enclosed Belt Conveyors