Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 34

29

PNEG-1204 Enclosed Belt Conveyors

Belting Assembly

13. The basic and primary rule which must be

kept in mind when tracking a conveyor belt is

simple, “THE BELT MOVES TOWARD

THAT END OF THE ROLL/IDLER IT CON-

TACTS FIRST.”

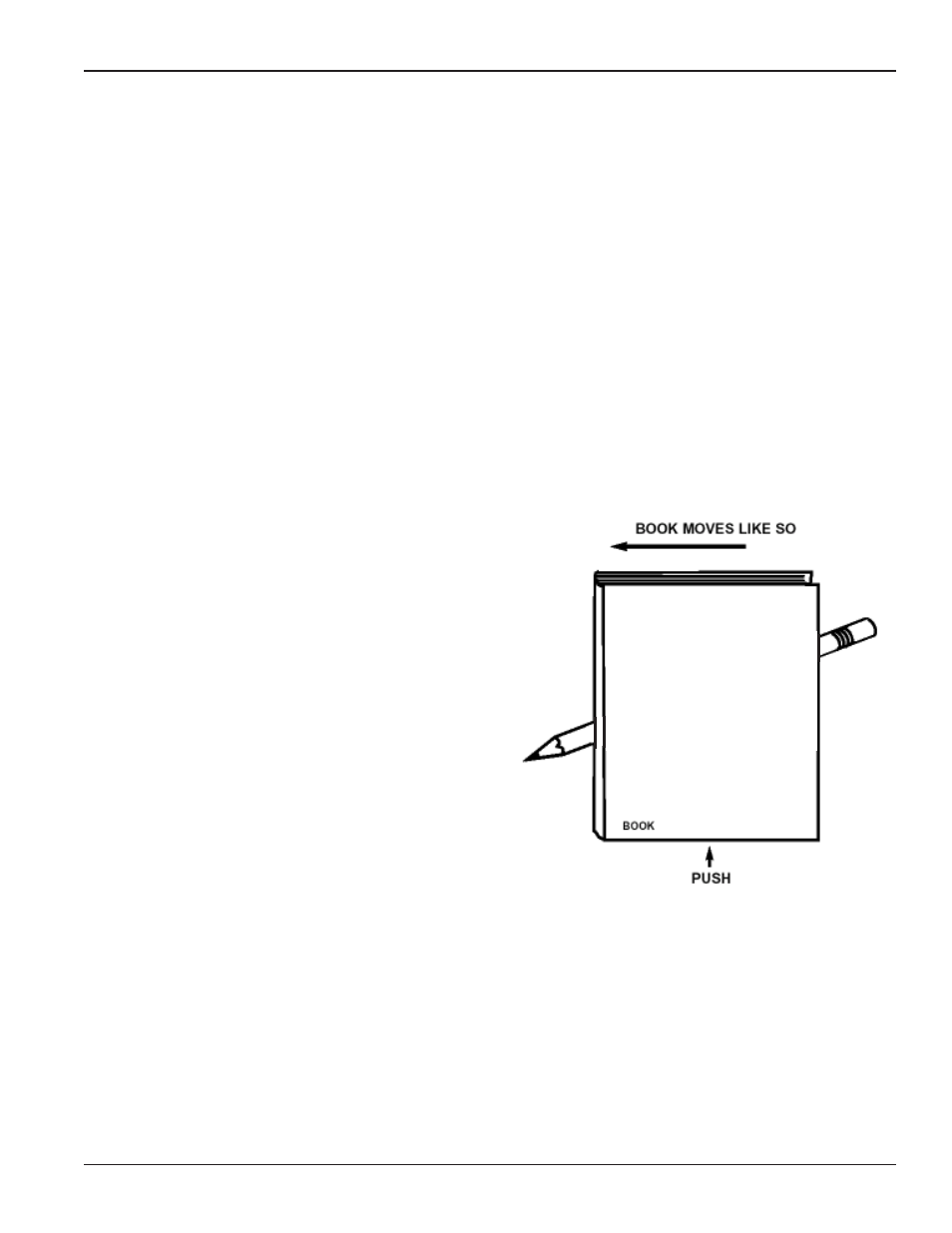

14. The reader can demonstrate this for himself

very simply by laying a small dowel rod or

round pencil on a flat surface in a skewed

orientation. If a book is now laid across the

dowel rod and gently pushed by one’s finger

in a line directly away from the experimenter,

the book will tend to shift to the left or right

depending upon which end of that dowel rod

the moving book contacts first.

6. Tracking the belt is a process of adjusting

idlers, pulleys, and loading conditions in a

manner that will correct any tendencies of the

belt to run other than true.

7. A normal sequence of training is to start with

the top pulleys in the direction of belt travel.

Start with the belt empty. After tracking is

completed, run the belt with a full load and

recheck tracking.

8. Tracking adjustment is done while the belt is

running and should be spread over some

length of the conveyor preceding the region

of trouble. The adjustment may not be imme-

diately apparent, so permit the belt to run for

several minutes and at least three full belt

revolutions after each idler adjustment to

determine if additional “tracking” is required.

9. After adjustment, if the belt has overcor-

rected, it should be restored by moving back

the same idler, and not by shifting additional

idlers or rollers.

10. If the belt runs to one side at a particular point

or points on the conveyor structure, the cause

will probably be due to the alignment, or

leveling of the structure, or to the idlers and

pulleys immediately preceding that particular

area, or a combination of these factors.

11. If a section or sections of the belt run off at all

points along the conveyor, the cause is

possibly in the belt itself, in the belt not being

joined squarely, or in the loading of the belt.

With regard to the belt, this will be due to

camber. Its condition should improve after it

is operated under full load tension. It is a rare

occasion when a cambered belt (less than

1/2%) needs to be replaced.

12. When replacing a used belt, go through the

system and square and level all rollers, idlers,

pulleys and bed before training a new belt.

General Tracking/Training Procedures