Options motion sensor option – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 38

33

PNEG-1204 Enclosed Belt Conveyors

Options

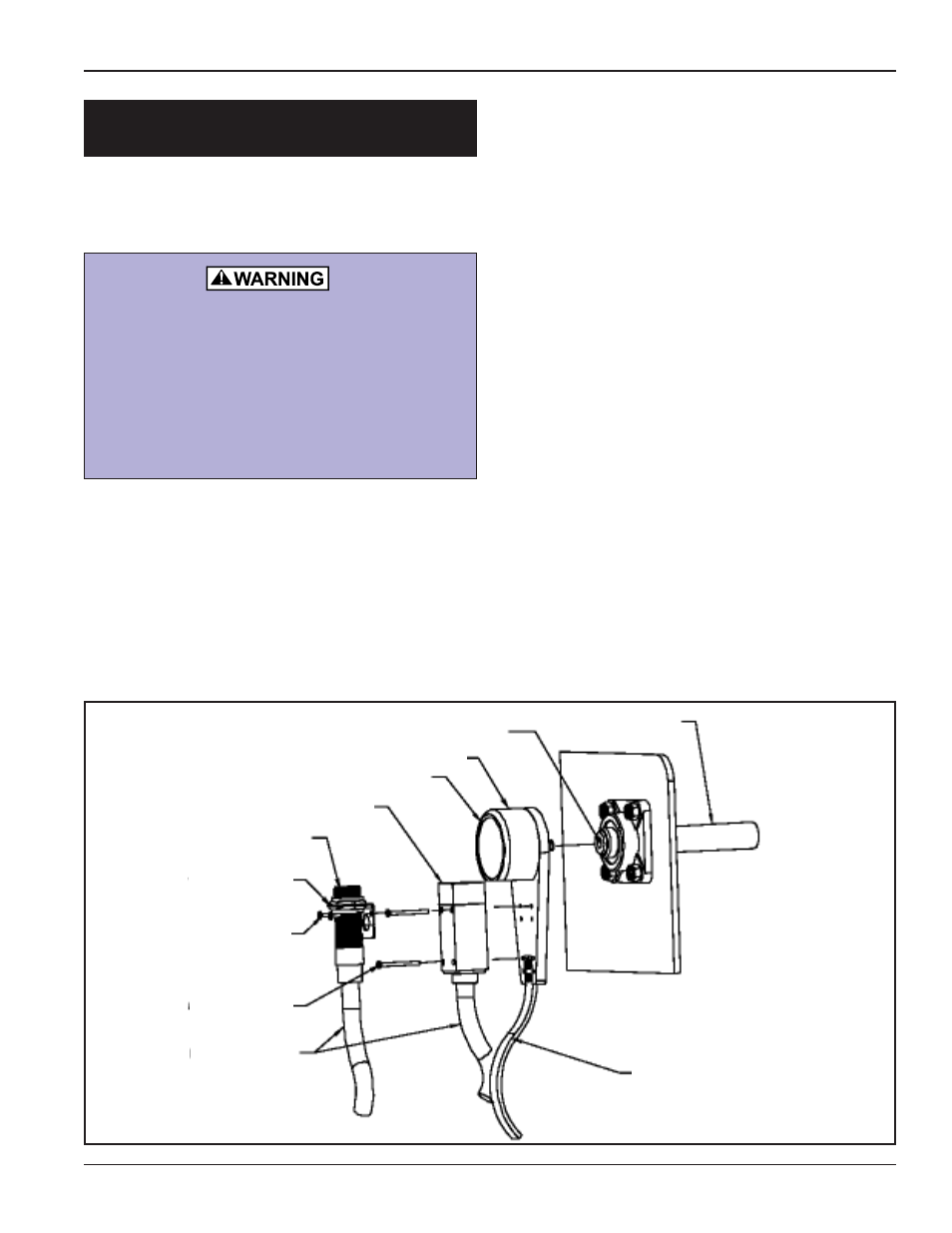

MOTION SENSOR OPTION

1. Shaft ends are predrilled and tapped from

the factory.

2. Thread the WHIRLIGIG onto the machine

shaft using 5/8" open ended wrench and

suitable thread locking adhesive (Loctite or

similar).

3. Install the sensor to the WHIRLIGIG base-

plate. Two sets of predrilled holes are pro-

vided for M800 sensor. Fit the sensor to

leave an approximate 2mm gap between

sensor face and cover.

A universal bracket (WGB18/30) is supplied

for fitting 18mm or 30mm sensors.

4. Connect the sensor in accordance with

manufacturer’s instructions and observe all

relevant electrical & OSHA regulations.

5. Fix the flexible strap securely to the static

structure. (If required).

TIP: The M800 speedswitch and system

function can be tested by placing a thin

metal plate between the sensor and the

cover of the WHIRLIGIG. When installing

other industry standard sensors, leave a

small gap between the sensor & the

WHIRLIGIG cover for this purpose.

WHIRLIGIG - WG1-4B

Installation Instructions

ALWAYS OBSERVE LOCKOUT AND TAG-

OUT PROCEDURES BEFORE, DURING

AND AFTER INSTALLATION.

DO NOT REMOVE THE WHIRLIGIG

COVER. THE ROTATING COMPONENTS

UNDER THE COVER COULD CAUSE

SERIOUS INJURY.

Monitored Shaft

Tap Shaft for 1/2" UNC Centered

Cover

The Whirligig

M800 Sensor

Cylindrical Sensor

18/30mm Bracket

(Supplied)

10mm Screws (4)

(Supplied)

50mm Screws (4)

(Supplied)

Flexible Conduit

Flexible Strap