Lubrication – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 46

Bushing Removal for Standard Taper or Short Shaft

Bushings:

1. Remove bushing screws.

2. Place the screws in the threaded holes provided in the

bushing flanges. Tighten the screws alternately and evenly until

the bushings are free on the shaft. For ease of tightening

screws make sure screw threads and threaded holes in the

bushing flanges are clean. If the reducer was positioned closer

than the recommended minimum distance “A” as shown in

Table 1, loosen the inboard bushing screws until they are clear

of the bushing flange by 1/8”. Locate two (2) wedges at 180

degrees between the bushing flange and the bushing backup

plate. Drive the wedges alternately and evenly until the bushing

is free on the shaft.

3. Remove the outside bushing, the reducer, and then the

inboard bushing.

LUBRICATION

IMPORTANT: Because reducer is shipped without oil, it is

necessary to add the proper amount of oil before operating

reducer. Use a high-grade petroleum base rust and oxidation

inhibited (R&O) gear oil - see tables. Follow instructions on

reducer warning tags, and in the installation manual.

Under average industrial operating conditions, the lubricant

should be changed every 2500 hours of operation or every 6

months, whichever occurs first. Drain reducer and flush with

kerosene, clean magnetic drain plug and refill to proper level

with new lubricant.

CAUTION: Too much oil will cause overheating and too little

will result in gear failure. Check oil level regularly. Failure to

observe this precaution could result in bodily injury.

Under extreme operating conditions, such as rapid rise and fall

of temperature, dust, dirt, chemical particles, chemical fumes, or

oil sump temperatures above 200°F, the oil should be changed

every 1 to 3 months, depending on severity of conditions.

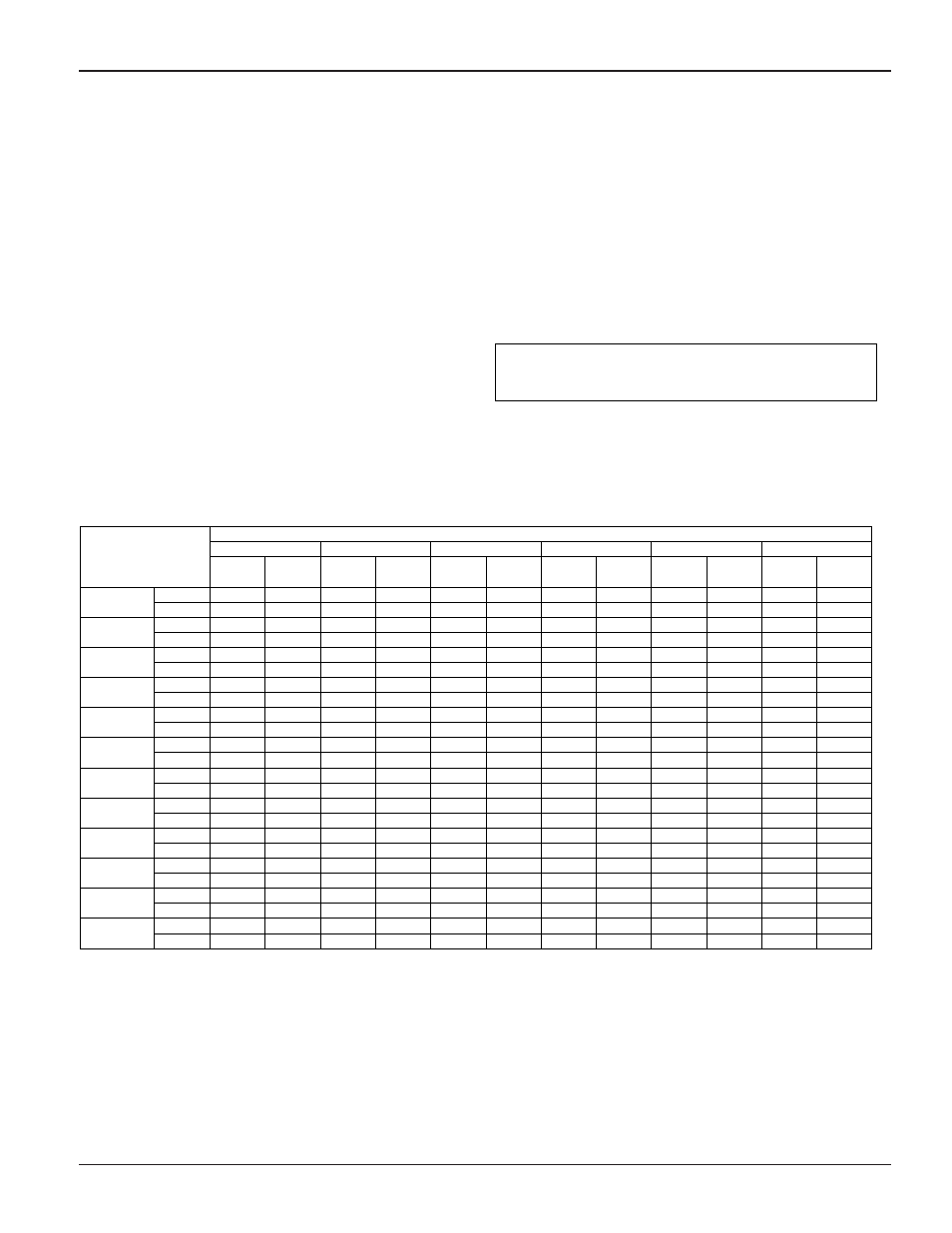

Table 2 – Oil Volumes

Approximate Volume of Oil to Fill Reducer to Oil Level Plug

Reducer

† Position A

† Position B

† Position C

† Position D

† Position E

† Position F

Size

▲Qt

L

▲Qt

L

▲Qt

L

▲Qt

L

▲Qt

L

▲Qt

L

Single

0.7

0.6

0.5

0.5

0.7

0.6

1.4

1.3

1.3

1.2

1.5

1.4

TA0107L

Double

0.7

0.6

0.5

0.5

0.6

0.6

1.3

1.3

1.2

1.2

1.4

1.3

Single

1.3

1.3

0.7

0.7

0.7

0.6

1.7

1.6

1.5

1.4

1.9

1.8

TA1107H

Double

1.3

1.3

0.7

0.7

0.6

0.6

1.7

1.6

1.5

1.4

1.9

1.8

Single

2.1

2.0

1.2

1.2

1.1

1.0

2.7

2.5

2.3

2.2

3.1

2.8

TA2115H

Double

2.1

2.0

1.1

1.1

1.0

1.0

2.6

2.5

2.4

2.3

3.0

2.9

Single

2.8

2.7

1.6

1.6

1.8

1.7

4.1

3.9

3.3

3.1

4.4

4.2

TA3203H

Double

2.8

2.7

1.5

1.4

1.7

1.6

4.0

3.8

3.4

3.3

4.2

4.0

Single

4.4

4.2

2.6

2.5

2.9

2.8

7.4

7.0

6.3

6.0

7.8

7.3

TA4207H

Double

4.4

4.2

2.5

2.4

2.8

2.6

7.3

6.9

6.4

6.0

7.5

7.1

Single

7.4

7.0

4.9

4.7

5.8

5.5

13.2

12.5

11.6

11.0

13.1

12.4

TA5215H

Double

7.4

7.0

4.7

4.4

5.5

5.2

12.9

12.2

11.4

10.8

12.6

11.9

Single

8.8

8.4

5.8

5.5

6.6

6.2

16.1

15.3

13.2

12.5

16.1

15.3

TA6307H

Double

8.8

8.4

5.5

5.2

6.2

5.9

15.8

15.0

13.9

13.1

15.3

14.5

Single

8.4

8.0

11.8

11.1

13.9

13.2

22.5

21.3

22.1

20.9

25.1

23.7

TA7315H

Double

8.4

8.0

10.8

10.3

13.2

12.5

22.0

20.9

22.4

21.2

23.1

21.8

Single

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

TA8407H

Double

7.7

7.3

11.7

11.1

13.7

12.9

25.1

23.8

24.0

22.7

25.8

24.4

Single

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

TA9415H

Double

17.0

16.1

16.8

15.9

18.1

17.1

33.2

31.4

33.2

31.4

38.6

36.5

Single

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

TA10507H

Double

38.0

36.0

27.6

26.1

25.8

24.4

53.5

50.6

53.8

50.9

56.1

53.0

Single

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

TA12608H

Double

53.0

50.2

41.5

39.3

37.1

35.1

70.7

66.9

72.2

68.3

80.4

76.1

Oil quantity is approximate. Service with lubricant until oil runs out of oil level hole.

† Refer to Figure 1 for mounting positions.

▲ US measure: 1 quart = 32 fluid ounces = .94646 liters.

Below 15 RPM output speed, oil level must be adjusted to reach the highest oil level plug. If reducer position is to vary from those shown in Figure 1, either more or less

oil may be required. Consult Dodge.

41

PNEG-1204 Enclosed Belt Conveyors