Belting assembly, Belt tension – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 31

26

PNEG-1204 Enclosed Belt Conveyors

Belting Assembly

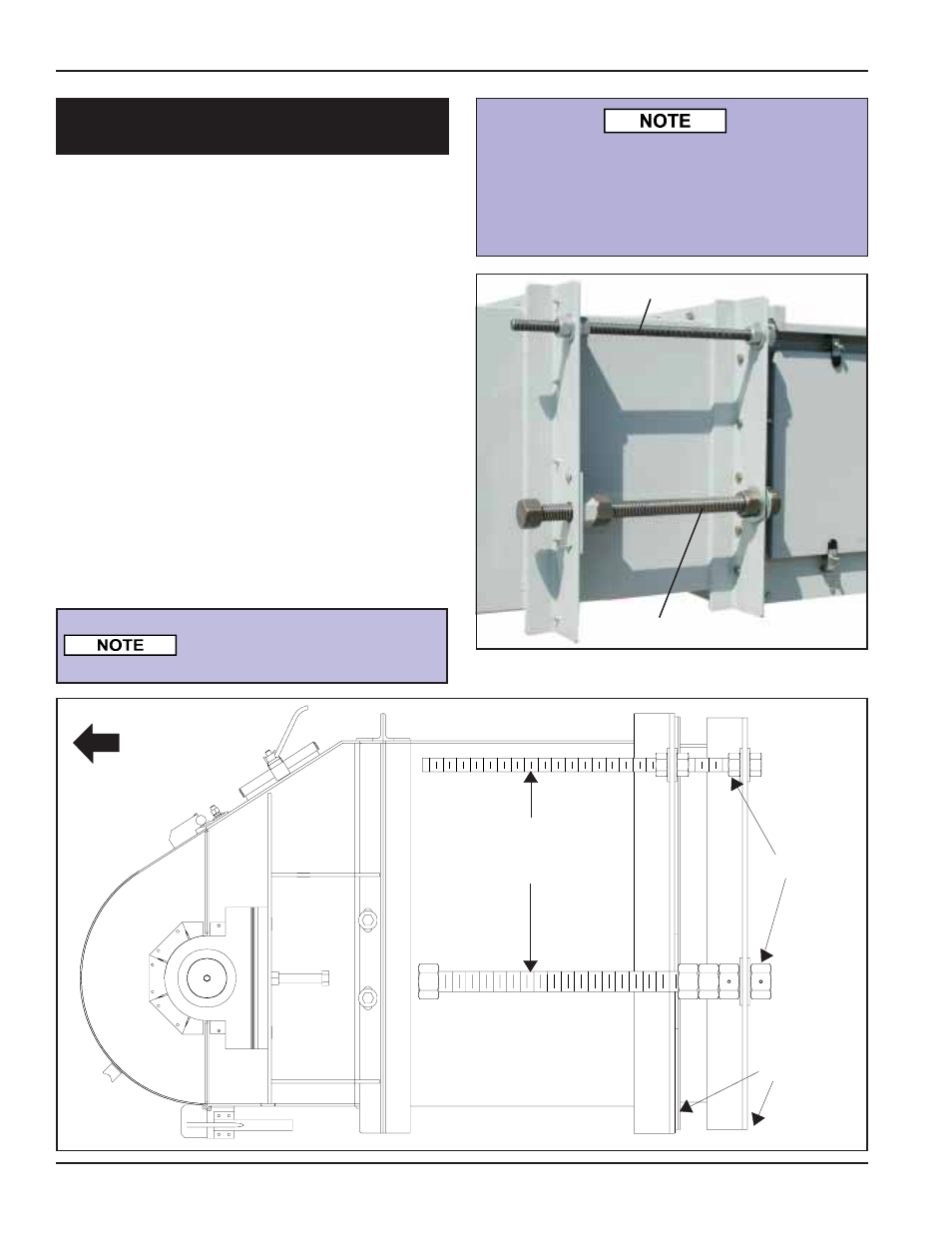

1. IMPORTANT: The belt tension should be

checked every day of use for the first few

days. Conveyor belts stretch when new and

must be checked at regular intervals. After

approximately two weeks of usage, checks of

belt tension may be done at less frequent

intervals.

2. After splice has been installed and 2" x 12"

piece of wood is removed, belt is ready to be

tightened.

3. The belt is tightened by turning the take-up

rods located on the tail section. Make sure

that they are adjusted equally to prevent

misalignment. The conveyor belt should be

tightened enough to prevent the belt from

slipping on the drive pulley. When done

adjusting take-up rods, tighten nuts against

flanges to lock in place.

After an hour of running, the belt should be

retightened and thereafter checked at

regular intervals. Take-Up Rods are for

tightening belt only. They are not to be

used to adjust belt tracking.

BELT TENSION

Take-Up Rod

TAIL SECTION

Flanges

Nuts

To tighten

belt tension,

adjust tail

section in this

direction.

Take-Up Rod

Do Not over tighten belt. Over

tightening can cause premature

wear of bearings and shafts.

Leveling Rod

Leveling Rod