Belting assembly squaring the belt end, Check the squareness of the belt cut – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 25

20

PNEG-1204 Enclosed Belt Conveyors

Belting Assembly

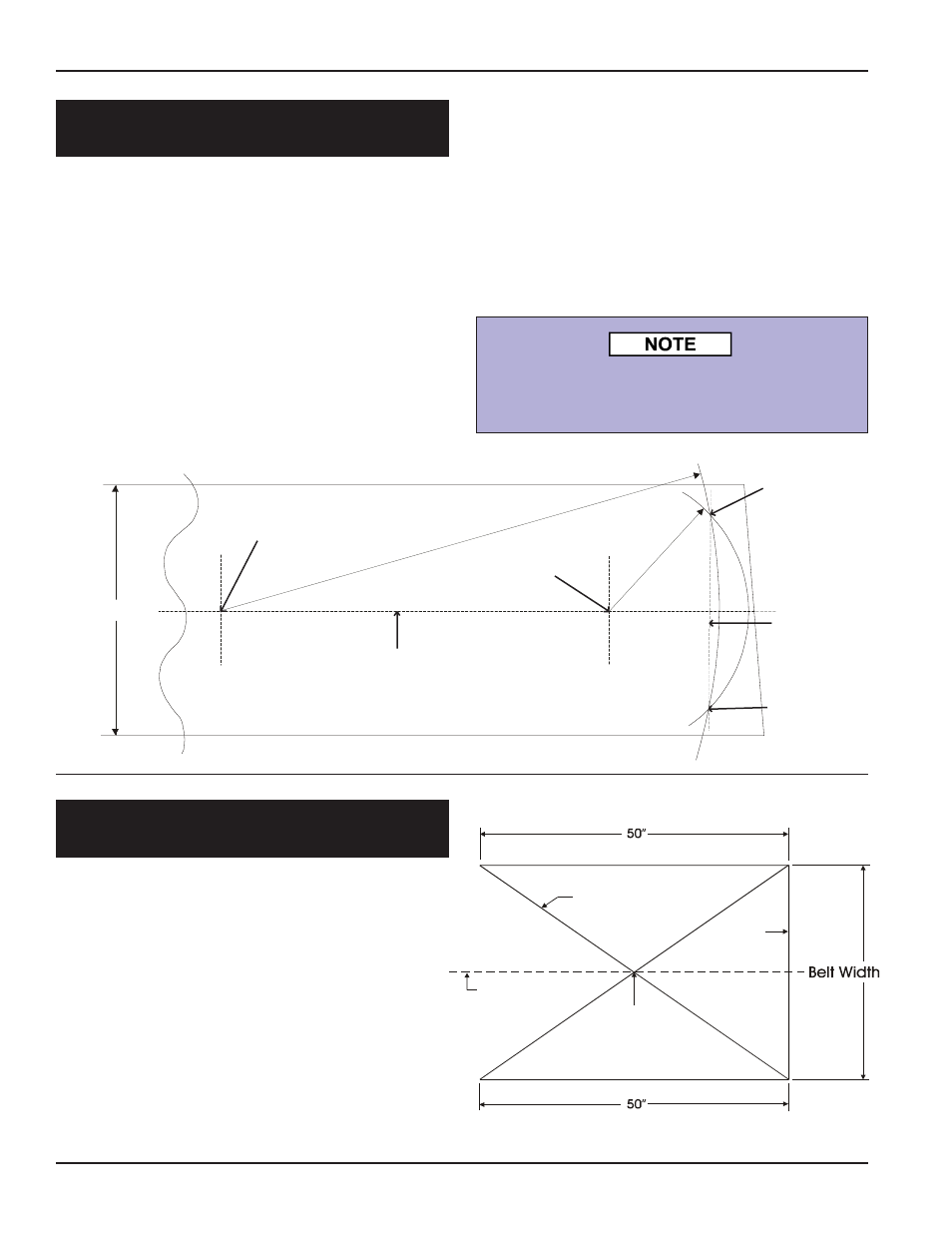

SQUARING THE BELT END

1. A double arc method is used on establishing

a cut line on the belt. After a center line has

been drawn, pick a point on the center line

about two times the belt width. From this

point, strike an arc across the width of the

belt end. A nail may be used as a pivot point

with twine used as the arm of the arc. Tie a

marking tool (chalk, for example) to the end

of the twine.

2. A second set of arcs is struck with the pivot

point of the arc on center line and close to

the belt end. Where the two arcs intersect

each other are points on which a cut line is

drawn.

The second arc should be slightly less than

half of the width of the belt.

CHECK THE SQUARENESS OF

THE BELT CUT

1. To check for the accuracy of the cut made,

measure lengthwise 50 inches from each

edge of the belt. Using a straight edge, draw

a line diagonally across the belt. This should

be done from the 50 inch point to the end

corner on the opposite side of the belt. Do

the same procedure in reverse to form an “x”.

The intersection point of the two lines of the

“x” should be in line with the center line of the

belt.

Diagonal Line

Intersection

Point

Belt

Centerline

Cut

Edge

of Belt

Belt Width

Pivot Point of

1st Arc

Pivot Point of

2nd Arc

Intersection

Point

Cut Line

Intersection

Point

Centerline