Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 User Manual

Page 37

32

PNEG-1204 Enclosed Belt Conveyors

Loading

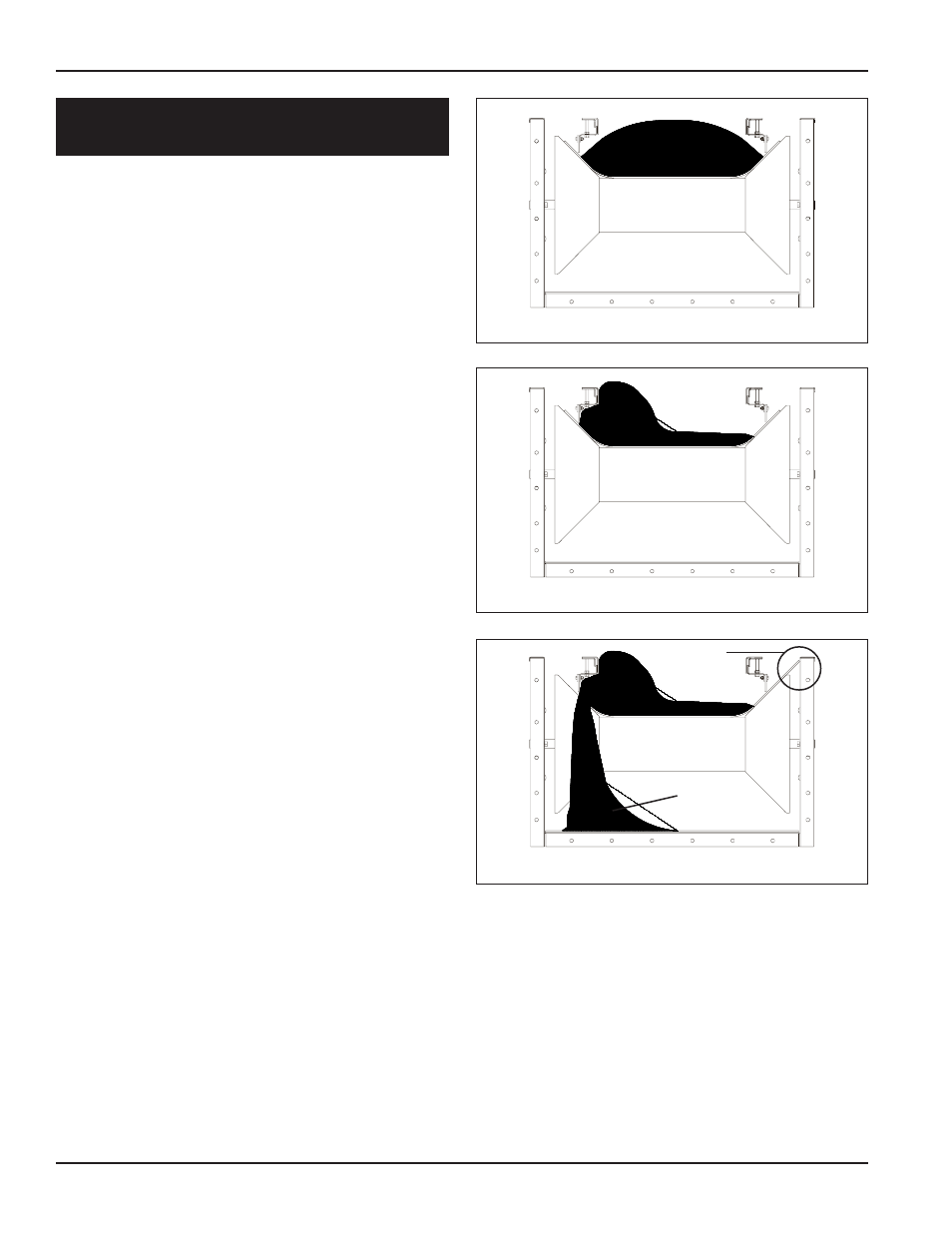

BELT CONVEYOR LOADING

1. Start with a light load and gradually work up

to the load that the conveyor was designed to

handle. Check chutes to see that the material

is being directed onto the center of the belt.

Off-center load will affect belt alignment in

that the belt will run off center. A central load

will maintain belt alignment.

2. The loading point of a belt conveyor is the

critical point. Here the conveyor receives its

major abrasion and practically all of its im-

pact. The ideal condition is to have the

material flow onto the belt at the same speed

and direction of travel as the belt, with a

minimum amount of impact, and to load the

belt on center.

3. Adjust the skirts to prevent side spillage of

material and to keep the load central on the

belt. The maximum distance between

skirtboards customarily is two thirds the width

of a trough belt.

4. The skirt lengths are designed to stop side

spillage. The material should also be at rest

on the belt before it reaches the end of the

skirt. If the material is still tumbling as it

passes the skirt end, the skirts should be

lengthened.

CORRECT - Evenly Loaded

INCORRECT - Loaded to One Side

EFFECT OF IMPROPER LOADING

Belt Shift

Spill