Veris Industries SDI SERIES Install User Manual

Page 3

22

3

Introduction

The Data Industrial SDI Series impeller flow sensor offers unpar-

alleled performance for liquid flow measurement in closed pipe

systems in an easy to install economical package. Impeller sensors

offer a quick response to changes in flow rate and are well suited to

flow control and batch type applications in addition to flow monitor-

ing. The new four-bladed impeller design is rugged, non-fouling and

does not require custom calibration.

Coupled with the proprietary patented digital detection circuit, the

sensor measures flows from under 0.3 feet per second to over

20 fps regardless of the conductivity or turbidity of the liquid. The

standard frequency output produces a low impedance square wave

signal proportional to flow rate that may be transmitted up to 2000

feet without amplification. Models are available to measure flow in

one or both directions.

All SDI insert sensors are mounted on the pipe using a 1” tap. As

with any insert sensor, a pipe saddle or weld-on fitting is preferred

over a service tee because it causes fewer disturbances to the flow.

Models Available

Direct insert sensor models are installed in piping configurations

that are not in service or under pressure.

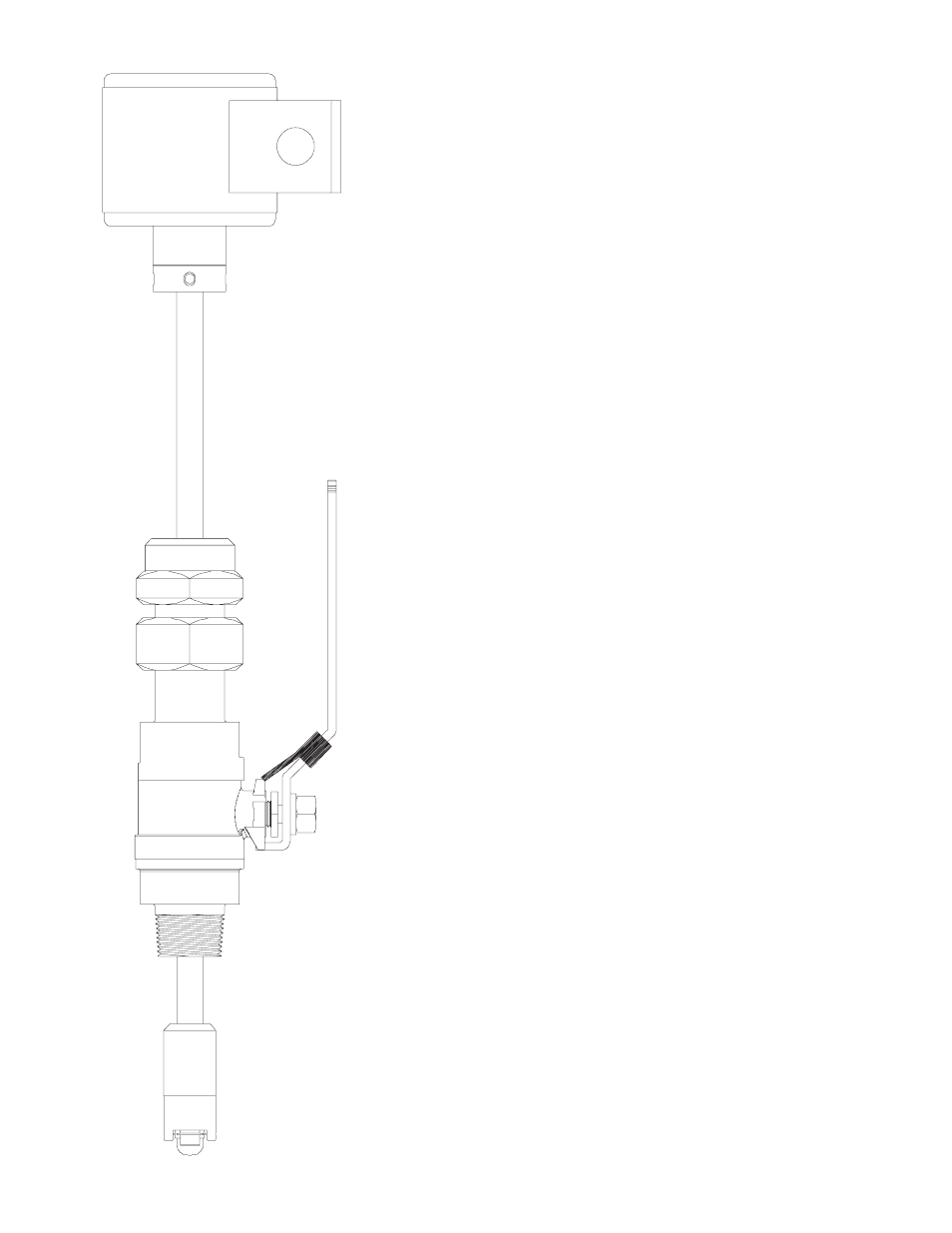

Hot tap insert sensor models feature isolation valves and mount-

ing hardware to install or remove the sensor from a pipeline that

would be difficult to shut down or drain. In a true “hot tap” installa-

tion the sensor is mounted in the pipe under pressure by attaching

a service saddle or weld-on fitting to the pipe and mounting the

isolating valve and nipple to the threaded connection. A hole is then

cut in the wall of the pipe through the valve using a commercial tap-

ping machine with a 1” size cutter. Once the hole is cut, the tapping

machine is removed and the valve is shut. Then the sensor assem-

bly is mounted to the isolation valve and extended into the pipeline

to measure flow.

Even in new construction a hot tap sensor may be appropriate for

service considerations.

The small stem diameter allows the sensor to be inserted into the

pressurized pipeline by hand without the need for an installation

tool. The mounting hardware holds the sensor firmly in place at the