Veris Industries SDI SERIES Install User Manual

Page 12

12

12

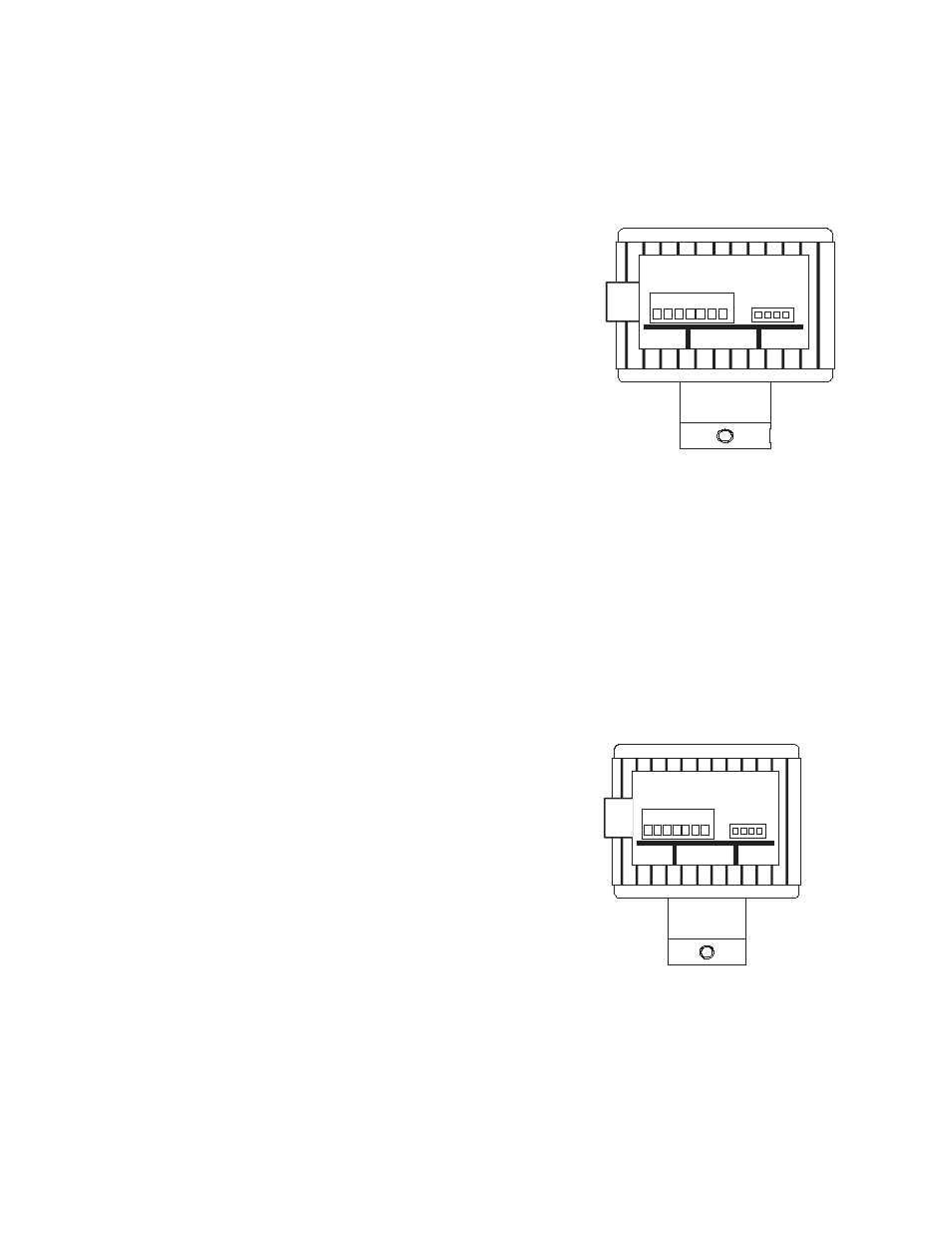

Bi-Directional Analog Output - Option “5” in the ordering matrix

This option provides a programmable 4-20 mA signal proportional to flow rate and a contact closure to indicate the

direction of flow. All programming is accomplished as previously mentioned. The user can program the unit for pipe

size, flow scale and the direction of flow. This is a six-wire option.

Attach

SDI #1 (Shield) to Earth Ground or Power Supply Common. (This provides maximum power and signal EMI

protection).

Attach

SDI #2 (Power -) to the negative terminal of a nominal

12-24VAC/VDC Power Supply. (See data sheet for current draw and voltage

limits).

Attach

SDI#3 (Power +) to positive terminal of power supply.

Attach

SDI #4 and SDI#5 (Direction +/-) to the device receiving the direc-

tional signal. (This connection is not polarity sensitive; and, when active,

provides a solid state switch closure for a maximum load of 100mA @30VAC

or +/-40VDC).

ANALOG OUTPUT – WIRED AS CURRENT SINKING

Attach

SDI#6 (Loop -) to the Analog input terminal of device receiving this

4-20mA signal.

Attach

SDI#7 (Loop +) to +24VDC terminal of device receiving the 4-20mA

Signal.

ANALOG OUTPUT – WIRED AS CURRENT SOURCING – SHARING SDI’s 24VDC POWER SUPPLY

Attach

SDI#6 (Loop -) to Analog input terminal of device receiving this 4-20mA signal.

Attach

SDI#7 (Loop +) to SDI#3. (Sharing terminal with +24VDC Supply).

Attach

SDI#2 (Loop -) to Analog Input Common. (Sometimes labeled Loop -).

ANALOG OUTPUT – WIRED AS CURRENT SOURCING – (WITH SEPARATE 24VDC POWER SUPPLY)

Attach

SDI#6 (Loop -) to Analog input terminal of device receiving this 4-20mA signal. (Sometimes labeled Loop +).

Attach

SDI#7 (Loop +) to +24VDC Supply terminal.

Attach -24VDC Supply terminal to the Analog Input Common. (Sometimes labeled Loop

-).

Bi-Directional Scaled Pulse Output - Option “6” in the ordering matrix

This option provides a programmable scaled pulse output signal proportional to flow rate and a contact closure to

indicate the direction of flow. All programming is accomplished as previously mentioned. The user can program

the unit for pipe size, flow scale and the direction of flow. This is a six-wire

option.

Attach

SDI #1 (Shield) to Earth Ground or Power Supply Common. (This

provides maximum power and signal EMI protection).

Attach

SDI #2 (Power -) to the negative terminal of a nominal

12-24VAC/VDC Power Supply. (See data sheet for current draw and voltage

limits).

Attach

SDI#3 (Power +) to positive terminal of power supply.

Attach

SDI #4 (Pulse B -) to the Input pulse (-) of the receiving device.

Attach

SDI #5 (Pulse B +) to the Input pulse (+) of the receiving device.

Attach

SDI #6 (Pulse A -) to the Input pulse (-) of the receiving device.

Attach

SDI #7 (Pulse A +) to the Input pulse (+) of the receiving device.

1. Shield

2. Power -

3. Power +

4. Direction

5. Direction

6. Loop -

7. Loop +

1 2 3 4 5 6 7

1. Shield

2. Power -

3. Power +

4. Pulse B -

5. Pulse B +

6. Pulse A -

7. Pulse A +

1 2 3 4 5 6 7