Figure 5, Electrical connections – M&C TechGroup EC-L Series Operator's manual User Manual

Page 13

13

Gas sampling and gas conditioning technology

3-3.1-ME

N O T E !

Attention must be paid to the requirements of IEC 364 (DIN VDE

0100) when setting high-power electrical units with nominal

voltages of up to 1000V, together with the associated standards

and stipulations.

An external main switch must be provided.

The main circuit must be equipped with a fuse of 10AT

(over

current protection); for electrical details see technical data (8.).

W A R N I N G !

Cooler versions with 115V resp. 120V have a built-in transformer

to generate an internal current of 230V. That means, device internal

live parts have a current of 230V not 115V/120V.

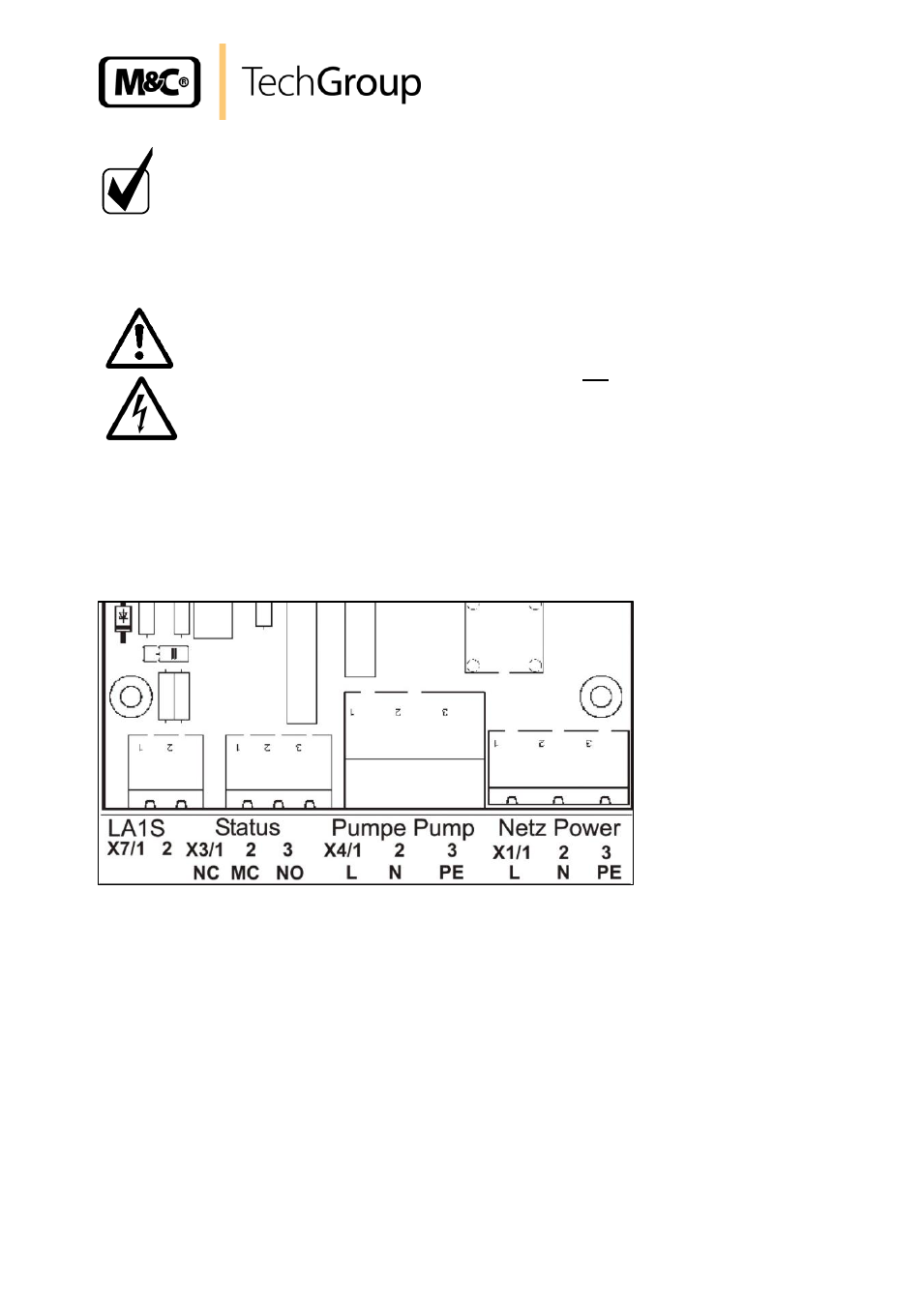

Figure 5 shows the electrical connections behind the front panel of the EC-L housing (fig. 2).

Alarms for excess- and low-temperature and liquid alarm (if connected) are given as a collective status

alarm via a relay output with a potential-free changeover contact. Alarm will be released if the current

temperature is out of a range of ±3°C referring to the set-temperature (+5°C) or if the liquid sensor

gets wet. A sample pump connected to terminal X4 will be switched off via an internal relay in case of

liquid alarm.

Figure 5 Electrical connections

The connection of the mains respectively , liquid alarm sensor, pump and status alarm signals

happens as follows:

release the captive screws (6 pcs.) at the cooler front and then swing open the front plate;

put the cables (6-12mm) through the cable glands M20 and connect them with the provided

plugs according to above mentioned wiring plan;

if a liquid alarm should be connected put the cable of the liquid alarm sensor through the cable

gland M12 and connect it with the provided plug according to above mentioned wiring plan;

the re-installation happens in the opposite way.