Reception, Preparation and installation, 10 reception – M&C TechGroup SP2100-H Operator's manual User Manual

Page 9: 11 preparation and installation

9

Gas sampling and gas conditioning technology

2-1.0-ME

Probe Structure:

The filter housing with its all-round heating element forms a unit with the standard mounting flange

DN65 PN6 and the laterally mounted electrical connection socket.

Mounting jaws are located at the aperture on the underside of the outer protective casing. These have

an integrated silicon cap for the connection of heated M&C sampling tubes with external diameters

of

40 mm to a max. 55 mm.

The probe sample gas outlet connection has a ¼" NPT internal thread to which the customer must

connect a suitable size of temperature resistant and threaded connector to connect the sample line in

a gas tight manner. These connectors can be supplied by M&C.

After assembly of the bolted pipe joint and of the sampling tube the sample gas outlet connection is

enclosed with the red silicon insulation provided. The mounting jaws and the integrated silicon cap

close off the connection to the exterior.

In order to sample gases, a one-meter long, stainless steel sampling tube is mounted in the mounting

flange. The maximum operating temperature for the sampling tube is 600° C.

Depending on the process gas temperature and composition or critical set up situations, heated probe

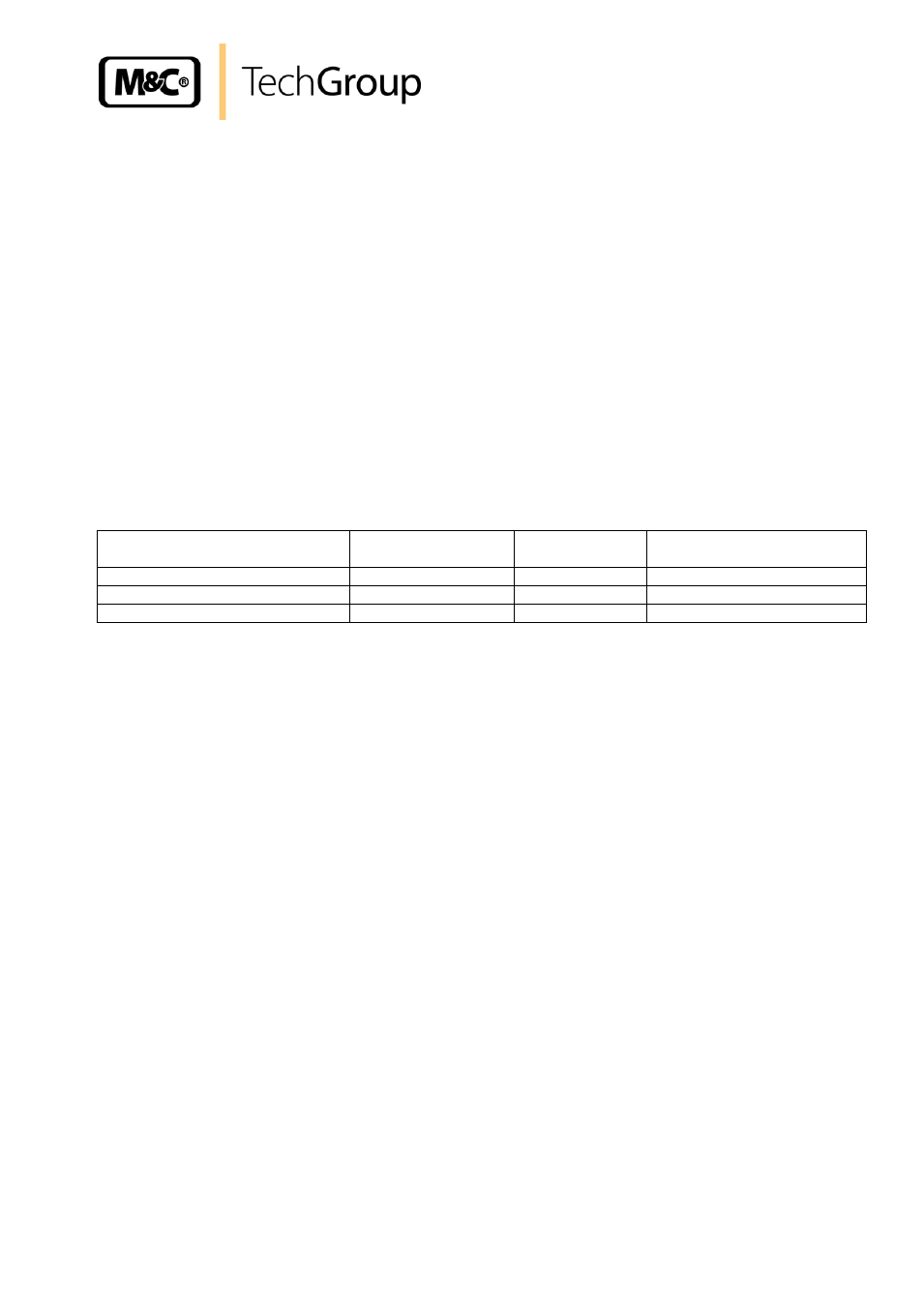

elements made of stainless steel with flange connection DN65 PN are used:

Type

Process

temperature

Length

Standard/max.

Tube, outer diameter

SP30H1, heating max. 320°C

up to max. 550 °C

1,0m / 2,0m

40mm

SP30H2, heating max. 200°C

up to max. 200 °C

1,0m / 2,0m

40mm

SP35H, heating max. 320°C

up to max. 550 °C

0,175m

40mm

10

RECEPTION

The gas sample probe is normally delivered in two packaging units:

1. The gas sample probe with the screws, nuts and flange seal required for mounting.

2. Sample tube with gasket.

The gas sample probe should be removed carefully from the packaging and checked immediately for

completeness against the delivery note.

Check the goods for any damage incurred during transport and if necessary inform your transport

insurer of any damage.

11

PREPARATION AND INSTALLATION

Select the optimal sampling point in accordance with the generally applicable guidelines or consult the

competent persons.

Locate the sampling point in such a way that there is adequate space for inserting and removing the

probe and pay attention to the insertion length of the probe tube.

Make certain that the probe is easily accessible so that you can carry out any subsequent

maintenance work without trouble.

Locate the probe connections in such a way that the connections' temperature is always above the

acid dew point in order to avoid corrosion and blockage problems. If this is not possible, a heated

SP35/SP30 probe tube is recommended for cold connections.