M&C TechGroup SR25.1_Ex Operator's manual User Manual

Page 16

16

Gas sampling and gas conditioning technology

3-7.1-ME

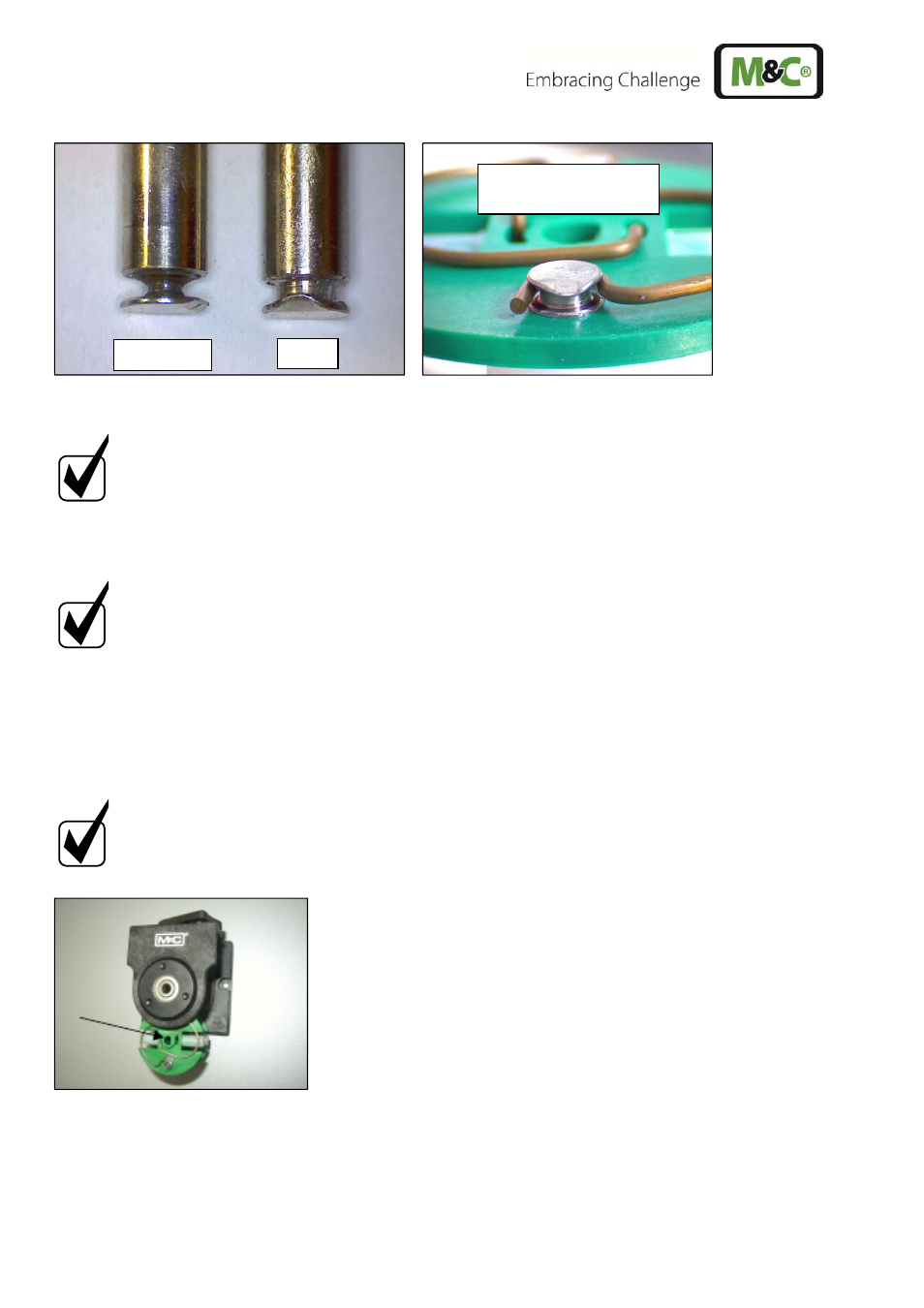

Figure 8 Check of axes and rolls

N O T E !

The springs may occur in different coulerings. This does not constitute a

quality defect. But make sure that the right spring strength is used. This

can be identified by the spring wire diameter. The „standard version for

Novoprene pump hoses“ (part no. 90P1010) has a diameter of 1,1mm and

the strengthened version for FPM-, Acidflex- or Masterflex-hoses“ (part

no. 90P1015) has a diameter of 1,2mm.

N O T E !

At first delivery two different types of springs are mounted in the driver

(right and left springs). When spare springs are ordered, for simplified

storage only one type will be delivered (right spring) that can be replaced

without any problems and guarantees full functionality when all four

springs are replaced.

Make sure that contact pulleys roll easily on the axis. After remounting the axis with contact

pulley into the driver the spring has to be mounted as shown in Figure 8. Please pay attention

to the alignment of the dent.

Remounting happens in reverse order.

N O T E !

While mounting pay attention to the fit of ‘rotational axisdriver’ and

check that the plunged boss at the shaft bore points to the front of the

pump head.

Use genuine spare parts only !

The dent prevents

rotation of the axis

new

worn out