Cleaning instructions, Accessories, Checking the horizontal beams – RIDGID micro DL-500 User Manual

Page 11

micro DL-500 Self-Leveling 5-Dot Laser

9

the laser to the surface that the mark is

on (this distance is L). L must be greater

than 12.5 feet (3,8 m).

4. Calculate the acceptable misalignment:

• in inches by multiplying L (in feet) by

0.005

• in millimeters by multiplying L (in me-

ters) by 0.417

5. Rotate the laser 180° clockwise by swivel-

ing the laser on its base (do not move the

base). Make sure that the down beam is

positioned on the reference point. Mark

the up beam location as position B.

6. Rotate the laser 90° clockwise by swivel-

ing the laser on its base (do not move the

base). Make sure that the down beam is

positioned on the reference point. Mark

the up beam location as position C.

7. Rotate the laser 180° clockwise by swivel-

ing the laser on its base (do not move the

base). Make sure that the down beam is

positioned on the reference point. Mark

the up beam location as position D.

8. Measure the distance between points A

and B and between points C and D. If the

distance between the points is greater

than acceptable misalignment calculat-

ed in step 4, have the laser serviced. This

cannot be field calibrated.

0º (A)

180º (B)

90º (C)

270º (D)

Figure 8 - Up Beam Check

Checking the Horizontal Beams

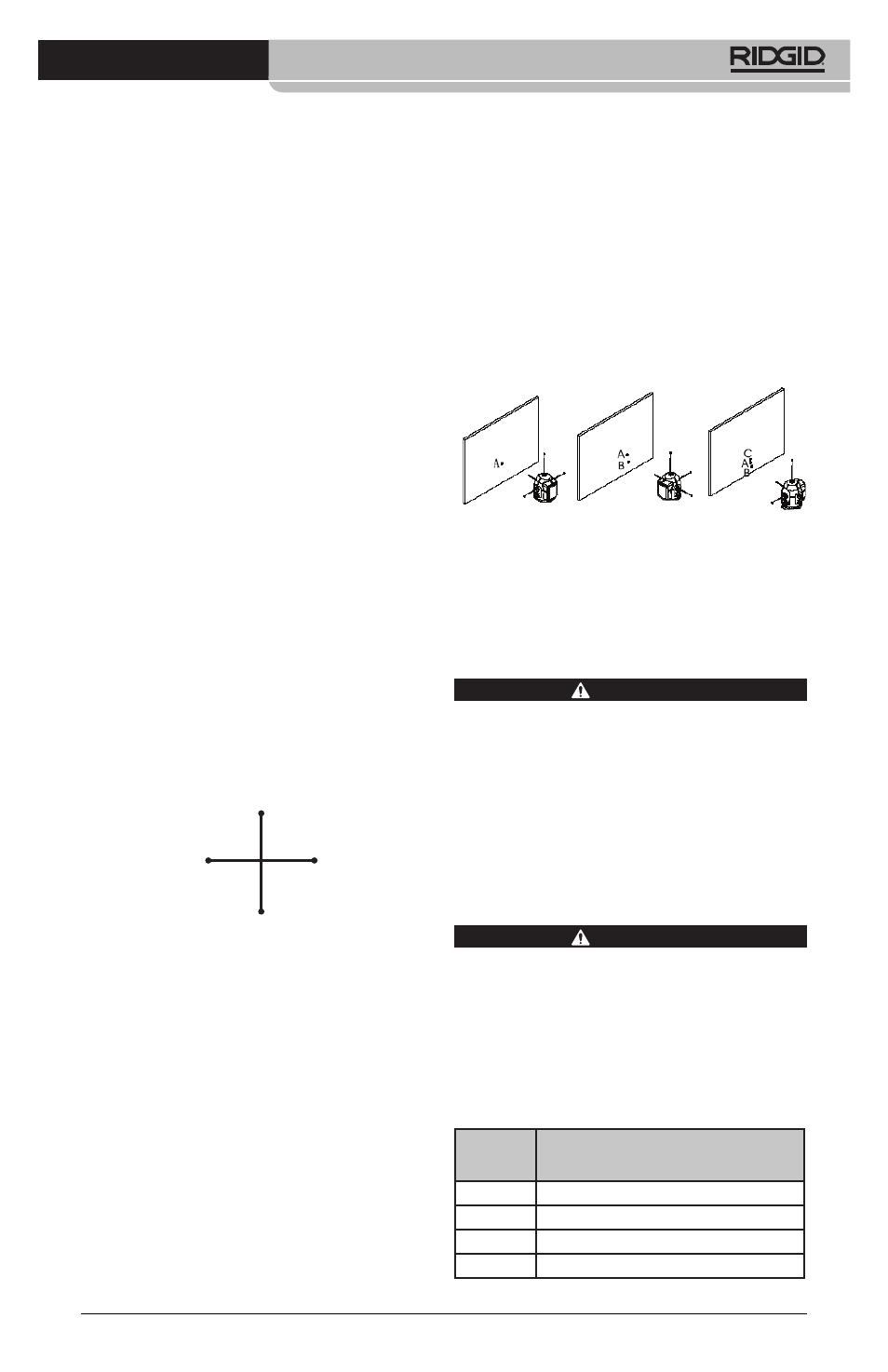

1. As shown in Figure 9, squarely set up the

laser on the tripod or flat surface 50 ft.

(15,2 m) from a wall.

2. Turn the laser ON.

3. Aim the front beam at the wall. Mark the

front beam location as position A.

4. Rotate the laser 90° by swiveling the la-

ser on its base (do not move the base)

to point the left laser beam at the wall.

Mark the left beam location as position

B.

5. Rotate the laser 180° by swiveling the

laser on its base (do not move the base)

to point the right laser beam at the wall.

Mark the right beam location as position

C.

6. Points A, B and C should all fall in a ver-

tical line. Vertically there should be no

more than 0.125" (3,2 mm) between the

highest and lowest points. If the mea-

surement exceeds 0.125" (3,2 mm), have

the laser serviced. This cannot be field

calibrated.

Figure 9 - Self-Checking the 3 Horizontal

Beams

Cleaning Instructions

WARNING

Remove the batteries before cleaning.

Keep the micro DL-500 Self-Leveling Laser

dry and clean. Do not immerse in water.

Gently wipe off with a damp soft cloth. Do

not use any detergents or solvents. Pay spe-

cial attention to the laser output windows –

remove any lint or fibers.

Accessories

WARNING

Remove the batteries before cleaning.

To reduce the risk of serious injury, only use

accessories specifically designed and recom-

mended for use with the RIDGID micro DL-500

Self-Leveling 5-Dot Laser such as those listed

below. Other Accessories suitable for use with

other tools may be hazardous when used with

the micro DL-500 Self-Leveling 5-Dot Laser.

Catalog

No.

Description

41723

Magnetic Base w/Mounting Strip

41373

micro DL-500 Laser Target Plate

41378

Laser Glasses

41383

Tripod