Level checks, Up beam check – RIDGID micro DL-500 User Manual

Page 10

micro DL-500 Self-Leveling 5-Dot Laser

8

3. Make sure the laser has been properly

inspected before each use.

4. Set up the micro DL-500 Laser for the ap-

plication. The laser unit can be mounted

directly to a tripod or other attachment

with the

5

/

8

" - 11 or

1

/

4

" - 20 thread. If us-

ing the base, align the tab on the base

mounting surface with the slot in the

bottom of the laser and secure with the

supplied

1

/

4

" - 20 screw.

The base can be placed on most rela-

tively flat, level surfaces. The base is also

equipped with magnets to allow mount

ing to steel objects in a variety of posi-

tions. Additionally, the base has top and

bottom sections that can be rotated rela-

tive to each other. See Figure 6 for com-

mon configuration.

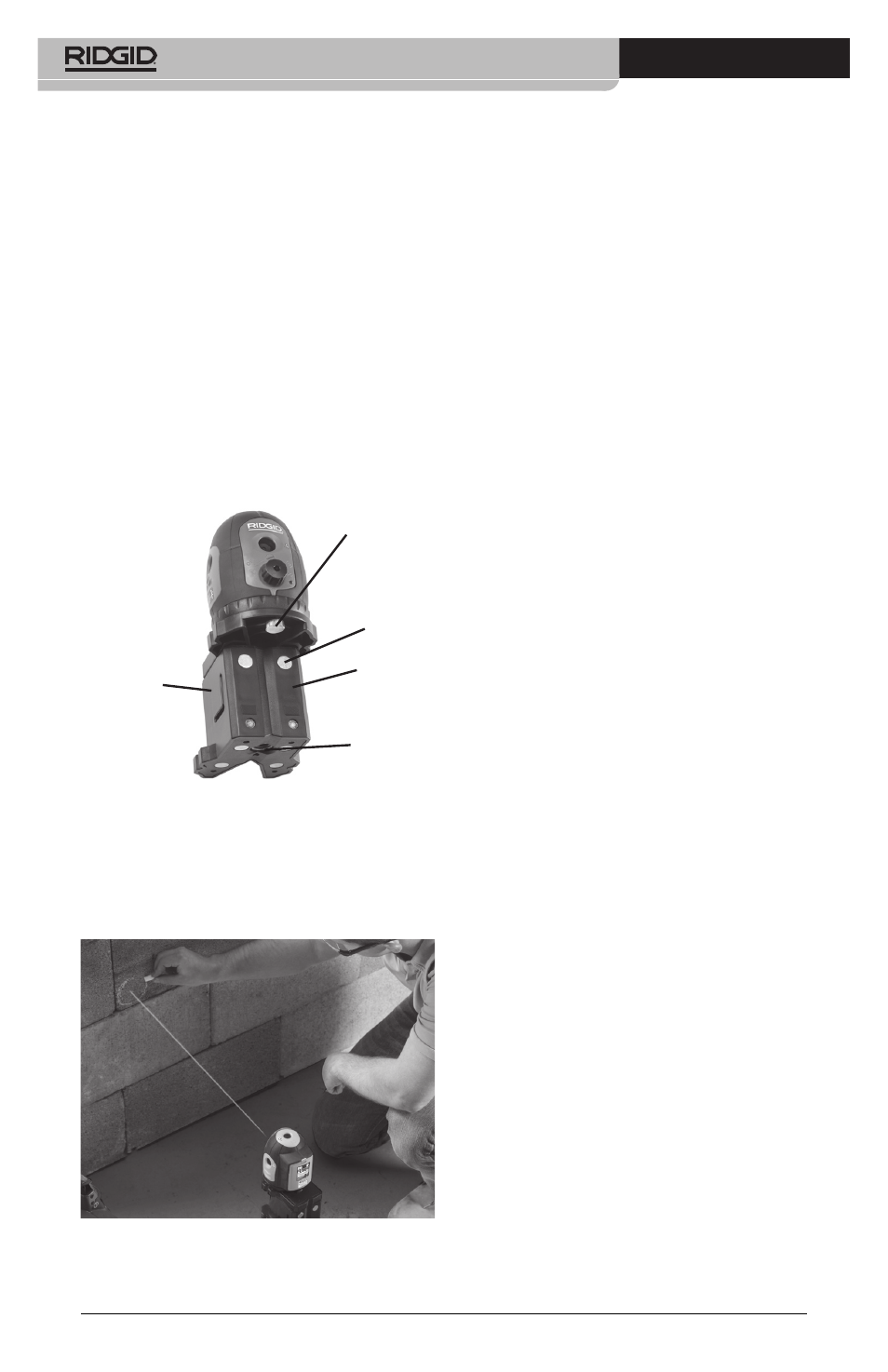

Strap Slots

1

/

4

" - 20

Screw

Magnets

Figure 6 -Base

5

/

8

" - 11

Thread

Base

In cases where the magnets will not

hold the laser in place (such as on plastic

pipe), use the mounting strap in the slots

on the base to retain the level in place.

Figure 7 - Using the mounting strap to hold

the Laser in position

Whatever configuration the laser is used

in, it must be secure and stable to pre-

vent the unit from tipping or falling. The

laser must be placed within +/-4.5 de-

grees of level to self level when turned

ON.

5. Keep your eyes and face clear of the la-

ser output windows. Turn the ON/OFF

switch fully clockwise. Five laser beams

will be generated (i.e. left, right, front,

up, and down) and will be visible as red

points on the adjacent surfaces. This will

also release the locking mechanism and

allow the laser unit to self-level. If the

laser is more than 4.5° from level, the

laser beam will flash and an intermittent

beep will sound. If this occurs, turn the

laser OFF and set up closer to level. De-

pending on the circumstances, the unit

should selflevel within a few seconds.

6. Once the laser is ON, the lasers can be

rotated to align with desired features. Do

not touch the laser unit while measure-

ments are being made – this can prevent

the laser from being level and give a false

reading. At this point, the laser beams

can be used as a reference point for mea-

surements, etc.

7. Any time the laser is not being used, turn

the laser OFF by turning the ON/OFF

switch counterclockwise to help prevent

inadvertent eye contact with the laser

beam.

8. While the laser is in the upright position,

lock the self-leveling mechanism prior to

transportation and storage by turning

the ON/OFF switch fully counterclock-

wise. Do not move the laser if the self-

leveling mechanism is not locked as this

can damage the unit.

Level Checks

Always check the Up Beam and the Horizontal

Beams prior to use to make sure that the unit

is properly leveling and calibrated.

Up Beam Check

1. With the laser attached to its base, set on

a flat surface inside a room. Turn the laser

ON.

2. Mark the location of the down beam on

the flat surface. This will be the reference

point.

3. Locate the up beam on the ceiling or sur-

face above the laser and mark its point

as position A. Measure the distance from