Toshiba B-850 User Manual

Page 71

APPENDIX 1 SPECIFICATIONS

EO1-33029

A1.3 Media

A1- 3

A1.3.1 Media Type (Cont.)

[Unit: mm]

Label dispensing mode

Item

Batch mode

Cut mode

Label: 38.0

c

Minimum media pitch

15.0

Tag: 25.4

d

Label length

Min. 12.5

Min. 32.0

e

Width including backing paper

100.0- 242.0

100.0 – 235.0

f Gap length

2.5 – 20.0

6.0 – 20.0

g

Black mark length (Tag paper)

2.0 – 10.0

h

Effective print width

216.8

±

0.2

i

Print speed up/slow down area

1.0

j

Black mark length (Label)

2.0 – 20.0

6.0 – 20.0

Max. print length

640.0

Maximum effective length for on the fly issue

320.0

Max. outer roll diameter

φ

230

Label + backing paper

0.13 – 0.18

Thickness

Tag

0.08 – 0.18

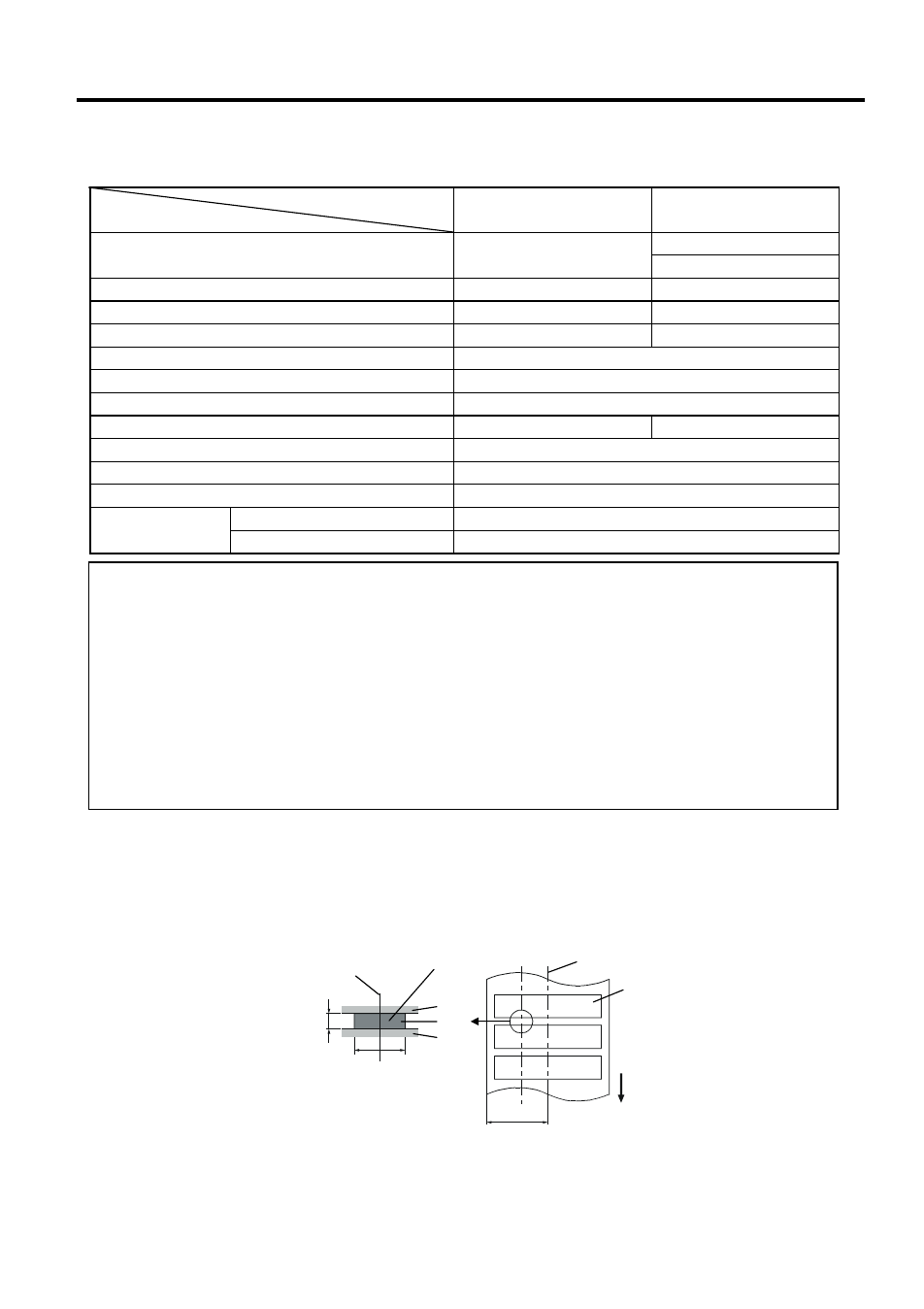

A1.3.2 Detection Area of the Transmissive Sensor

The transmissive sensor is movable from the center to the left edge of media.

The transmissive sensor detects a gap between labels, as illustrated below.

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC specified media.

2. When using the cutter ensure that label length

d plus inter-label gap length f exceeds 38 mm.

(i.e. label pitch should be greater than 38 mm.)

3. When requesting black marks on label rolls, the following requirements must be satisfied.

When the gap length is less than 4 mm:

The black mark length should be longer than the gap length.

When the gap length is 4 mm or more:

The black mark should not overlap the gap for more than 4 mm or the following label.

Black marks should be printed on reverse side of the gaps. Also, they should contact or overlap the

preceding label’s bottom end line.

4. “On the fly issue” means that the printer can feed and print without stopping between labels.

Sensor position

Area to be detected.

Center of media

Print side

Min. 12 mm

Label

Gap

Label

Min. 2.0 mm

(Min. 6.0 mm when using

the cutter module.)

Sensor is movable

within this range.

Media feed direction