Electrical connections, Terminal strip connection options, Installation & service manual – Lochinvar COPPER-FIN 497 - 2067 User Manual

Page 38

38

5

Electrical connections

External EMS connection to terminal

strip for stage firing control of

burners

This unit is equipped with a factory installed terminal strip

for connection of an energy management system (EMS)

to the burner stages. The EMS terminal strip is located

in the unit’s control panel. Ensure that all wiring used

for connection to this terminal strip is properly sized per

the recommendations in TABLE 5A. When connecting

an EMS to this terminal strip to sequence on each stage

of burner operation, the unit’s internal thermostat or

electronic sequencer should be set as an additional high

limit control. This will prevent problems between the set

points of the EMS and the boiler’s internal controller.

Terminal strip connection options

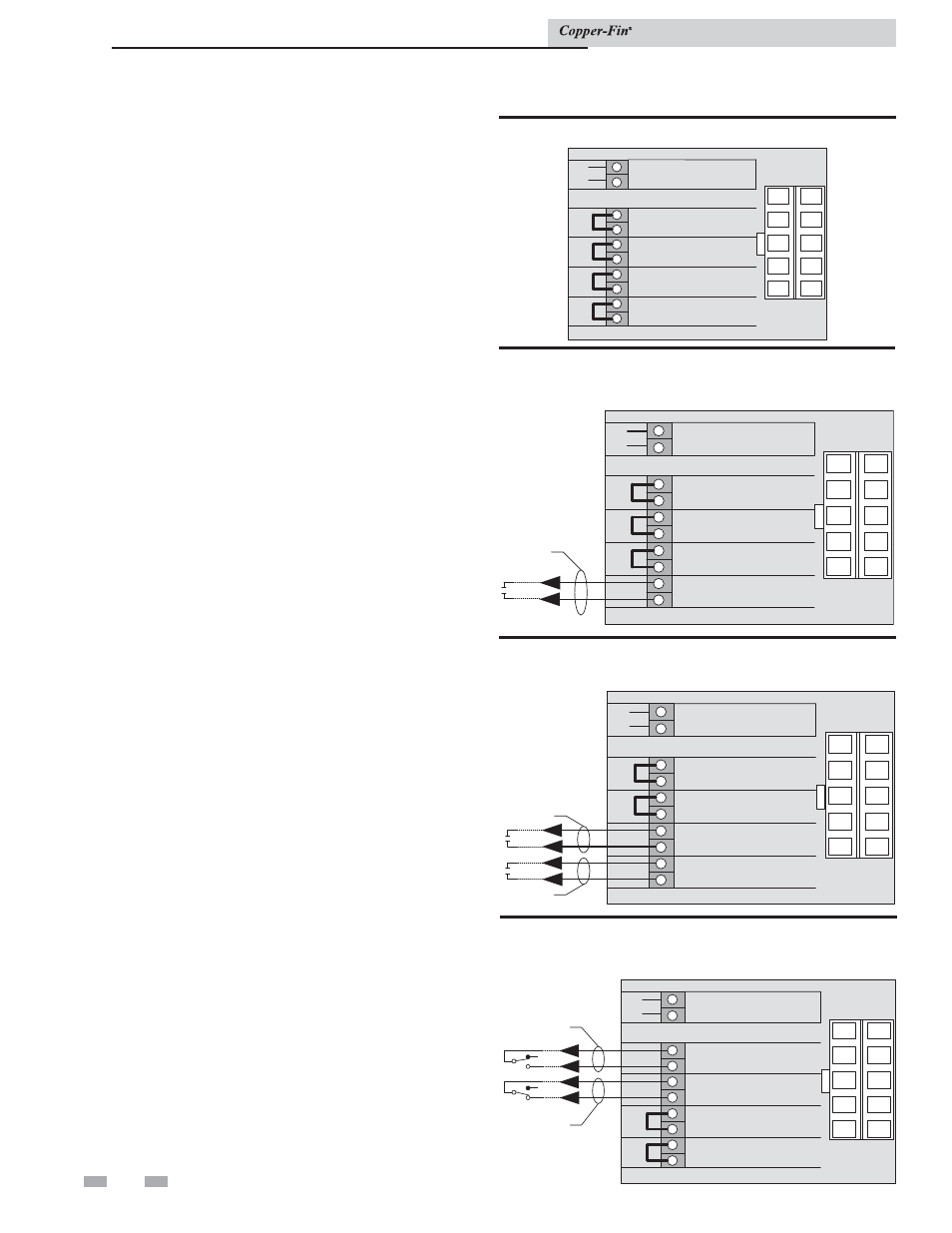

Figure 5-2 shows the position of jumpers as shipped from

the factory for stand-alone operation of boilers or water

heaters.

Figure 5-3 shows connections to the terminal strip for

Remote ON/OFF control of the boiler or water heater.

The 1C-1NO jumper must be removed when making

these wiring connections. This remote ON/OFF control

will provide an Enable/Disable signal to the unit and allow

the unit to operate based on the stage set points, until the

remote ON/OFF signal is cancelled.

Figure 5-4 shows the connections necessary to operate the

unit as a two-stage (High/Low Fire) boiler or water heater

from an Energy Management System (EMS). The actual

set point temperatures are controlled by the EMS. The

High Fire Offset on the electronic temperature control in

the unit must be set to zero and the set point must be set

to a value which will function as an upper limit for proper

operation under this two-stage control from an EMS.

Figure 5-5 shows the Continuous and Intermittent

terminals. External safety devices connected to these

terminals will function to protect the unit. Devices

connected to the Intermittent terminals (B1 and B2) are

monitored only when there is an active Call for Heat.

Devices connected to the Continuous terminals (A1

and A2) are monitored continuously and will activate

an alarm (if the unit is equipped with the alarm option)

anytime the safety device senses an abnormal condition.

1

2

3

4

5

6

7

8

9

10

+

+

+

+

+

+

+

+

+

+

SYSTEM/TANK

SENSOR

B2

B1

A2

A1

2 NO

2 C

1 NO

1 C

INTERMITTENT

LIMITS

CONTINUOUS

LIMITS

HIGH FIRE

ENABLE

LOW FIRE

ENABLE

9

8

7

6

4

3

2

1

10

5

1

2

3

4

5

6

7

8

9

10

+

+

+

+

+

+

+

+

+

+

SYSTEM/TANK

SENSOR

B2

B1

A2

A1

2 NO

2 C

1 NO

1 C

INTERMITTENT

LIMITS

CONTINUOUS

LIMITS

HIGH FIRE

ENABLE

LOW FIRE

ENABLE

9

8

7

6

4

3

2

1

10

5

Remote

on/off

Stage 1

1

2

3

4

5

6

7

8

9

10

+

+

+

+

+

+

+

+

+

+

SYSTEM/TANK

SENSOR

B2

B1

A2

A1

2 NO

2 C

1 NO

1 C

INTERMITTENT

LIMITS

CONTINUOUS

LIMITS

HIGH FIRE

ENABLE

LOW FIRE

ENABLE

9

8

7

6

4

3

2

1

10

5

Stage 2

Continuous

Alarms

1

2

3

4

5

6

7

8

9

10

+

+

+

+

+

+

+

+

+

+

SYSTEM/TANK

SENSOR

B2

B1

A2

A1

2 NO

2 C

1 NO

1 C

INTERMITTENT

LIMITS

CONTINUOUS

LIMITS

HIGH FIRE

ENABLE

LOW FIRE

ENABLE

9

8

7

6

4

3

2

1

10

5

Intermittent

Alarms

Figure 5-2_Stand-alone operation

Figure 5-5_Field installation safety devices

Figure 5-4_Two-stage (high/low fire) boiler or water

heater

Figure 5-3_Remote on/off boiler or water heater

Installation & Service Manual