Water connections, Installation with a chilled water system, Boiler flow rate – Lochinvar COPPER-FIN 497 - 2067 User Manual

Page 35

35

4

Water connections

(continued)

Installation with a chilled water

system

Pipe refrigeration systems in parallel. Install duct coil

downstream at cooling coil. Where the hot water heating

boiler is connected to a heating coil located in the air handling

units which may be exposed to refrigeration air circulation, the

boiler piping system must be equipped with flow control valves

or other automatic means to prevent gravity circulation of the

boiler water during the cooling cycle.

The coil must be vented at the high point and hot water from the

boiler must enter the coil at this point. Due to the fast heating

capacity of the boiler, it is not necessary to provide a ductstat to

delay circulator operation. Also, omit thermostat flow checks

as the boiler is cold when heating thermostat is satisfied. This

provides greater economy over maintaining standby heat.

Boiler flow rate

Typical heating boiler installations

General plumbing rules:

1. Check all local codes.

2. For serviceability of boiler, always install unions.

3. Always pipe pressure relief valve to an open drain.

4. Locate system air vents at highest point of system.

5. Expansion tank must be installed near the boiler and on the

suction side of the system pump.

6. Support all water piping.

ƽ CAUTION The maximum flow rate for Models 497-

747 is 55 GPM and 90 GPM on Models

987 - 2067. Do not exceed the maximum

flow rate of the heating boiler. If higher

flow rates are required through the boiler,

an optional Cupro-Nickel heat exchanger

is available. When using a Cupro-Nickel

heat exchanger, GPM can be increased by

30 percent. Consult the factory for specific

application requirements.

The heat exchanger is generally capable of operating within

the design flow rates of the building heating system. Should

the flow rate exceed the maximum allowable flow rate through

the boiler an external bypass must be installed. The bypass

should be fully sized with a balancing valve to allow for proper

adjustment of flow. Flow rate can be determined by measuring

the temperature rise through the boiler.

Installation & Service Manual

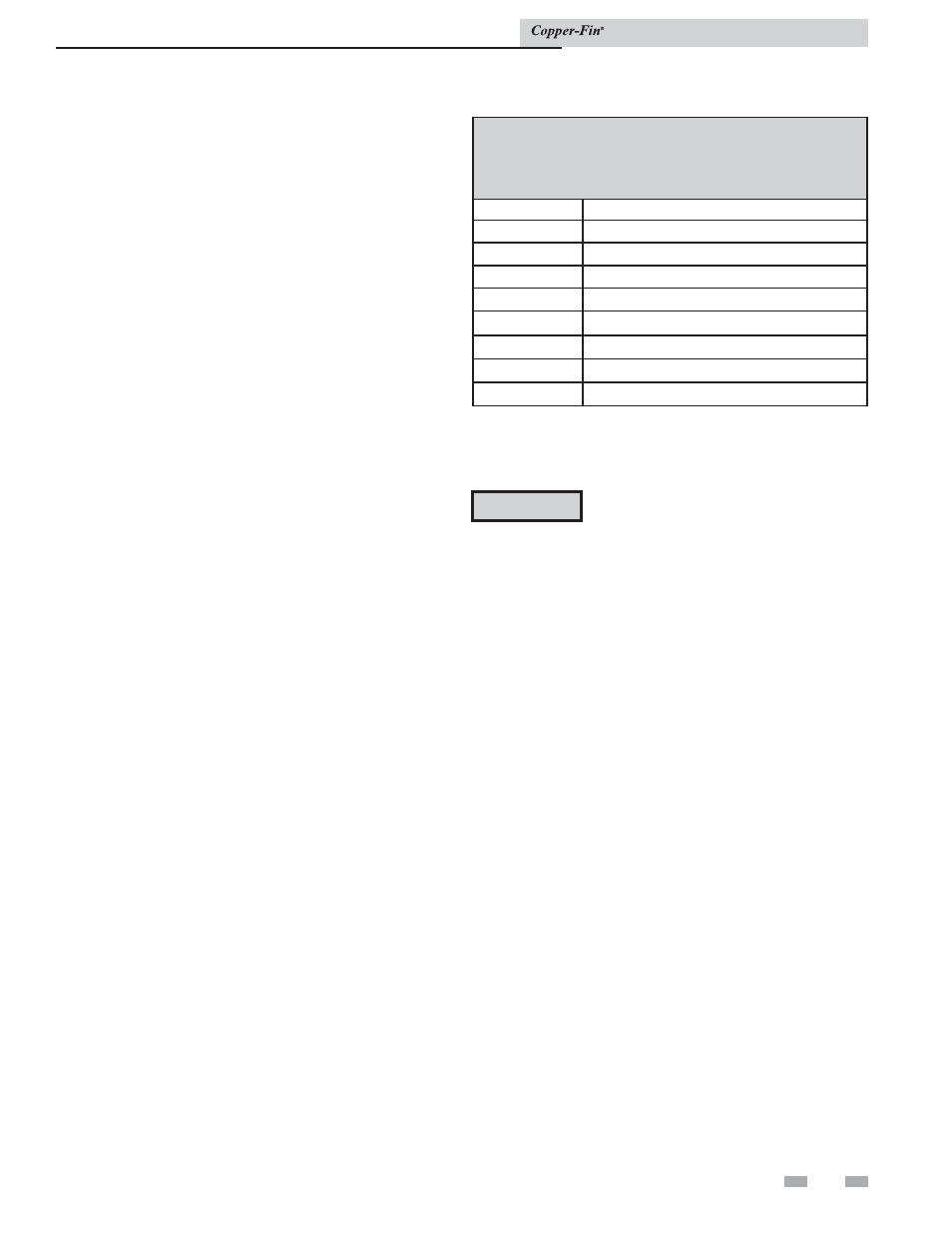

TABLE - 4C

BOILER TEMPERATURE RISE AT MAXIMUM FLOW

Temperature Rise at Full Rate Fire, 55 and 90 GPM

Maximum Flow

Model

Temperature Rise °F

497

15 @ 55 GPM

647

20 @ 55 GPM

747

23 @ 55 GPM

987

19 @ 90 GPM

1257

24 @ 90 GPM

1437

27 @ 90 GPM

1797

34 @ 90 GPM

2067

39 @ 90 GPM