Venting – Lochinvar COPPER-FIN 497 - 2067 User Manual

Page 17

17

2

Venting

(continued)

Barometric damper location

Any venting system option that requires a barometric

damper must adhere to the following directions for optimum

performance. The preferred location for the barometric damper

is in a tee or collar installed in the vertical pipe rising from the

unit’s flue outlet. The barometric damper MUST NOT be

installed in a bull head tee installed on the unit’s flue outlet.

The tee or collar containing the barometric damper should

be approximately three feet vertically above the connection to

the unit’s flue outlet. This location ensures that any positive

velocity pressure from the unit’s internal combustion fan is

dissipated and the flue products are rising due to buoyancy

generated from the temperature of the flue products. Adjust

the weights on the damper to ensure that draft is maintained

within the specified ranges.

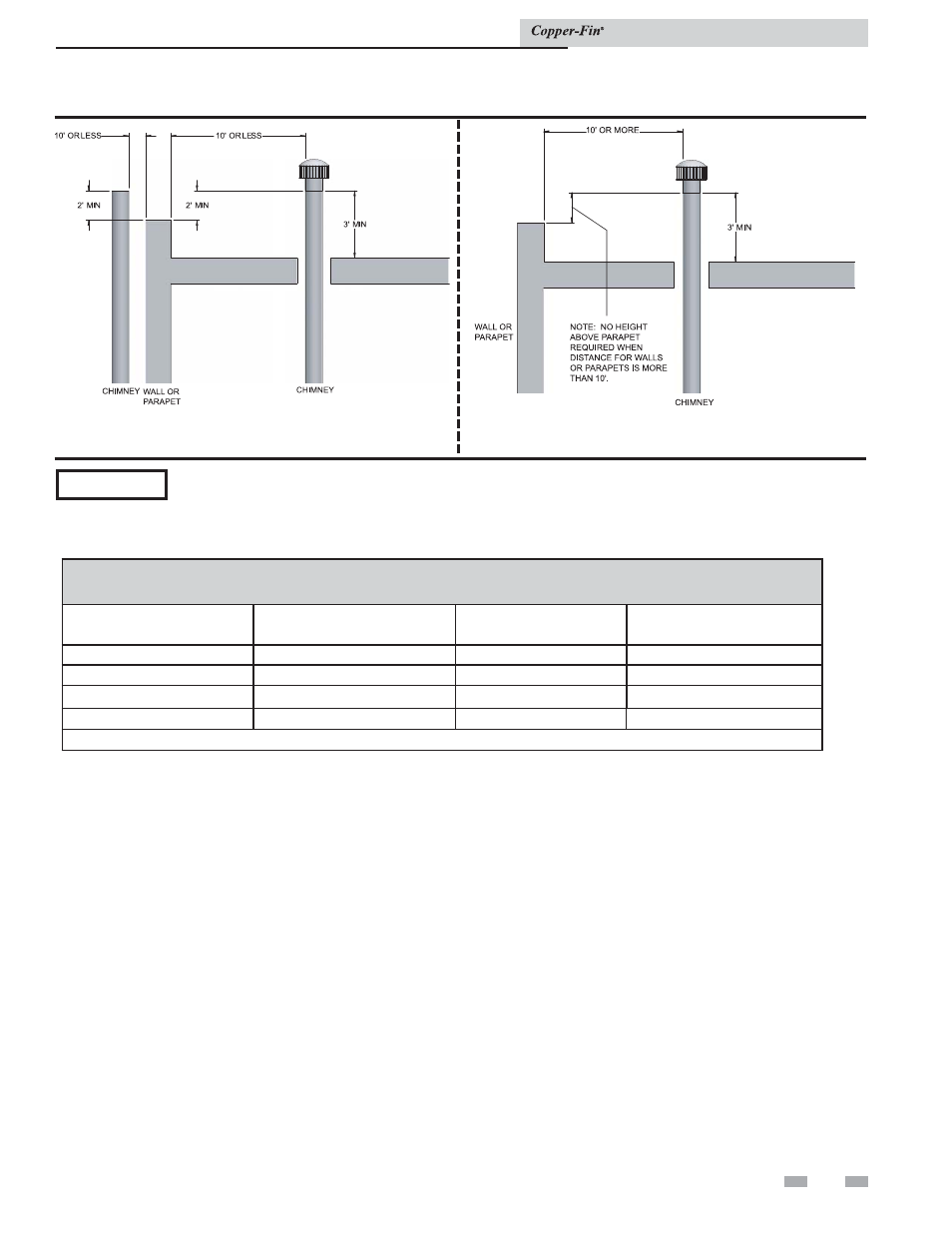

Figure 2-4_Vent termination from flat roof - 10 ft. or more

from parapet wall

Figure 2-3_Vent termination from flat roof - 10 ft. or

less from parapet wall

Vent system options

Vent System Options

This unit has two venting options.

1. Conventional

Negative

Draft

Venting

This option uses a vertical rooftop flue termination.

Combustion air is supplied from the mechanical room.

See page 15 for detailed information.

2. Outdoor

Installation

Venting

This option uses the installation of special air inlet and

vent caps on the unit.

All units are shipped from the factory equipped for

conventional negative draft venting. All other optional vent

systems require the installation of specific vent kits and venting

materials. The following is a detailed explanation of the

installation requirements for each venting system, components

used and part numbers of vent kits for each model.

ƽ CAUTION Units which are shut down or will not operate may experience freezing due to convective air flow in flue

pipe, through the air inlet, or from negative pressure in the equipment room. In cold climates, operate pump

continuously to help prevent freezing of boiler water. Provide proper freeze protection. See Freeze Protection,

page 46.

TABLE 2A

FLUE PIPE SIZES

MODEL

FLUE SIZE

MODEL

FLUE SIZE

497

6''

1257

12''

647

8''

1437

12''

747

8''

1797

14''

987

10''

2067

14''

Installer may increase diameter one pipe size for ease of installation, if needed.

Installation & Service Manual