Kodak 7520 User Manual

Page 91

8-16

A-61140 January 2000

Table 2 identifies the most common causes of low bar code

ratings/grades.

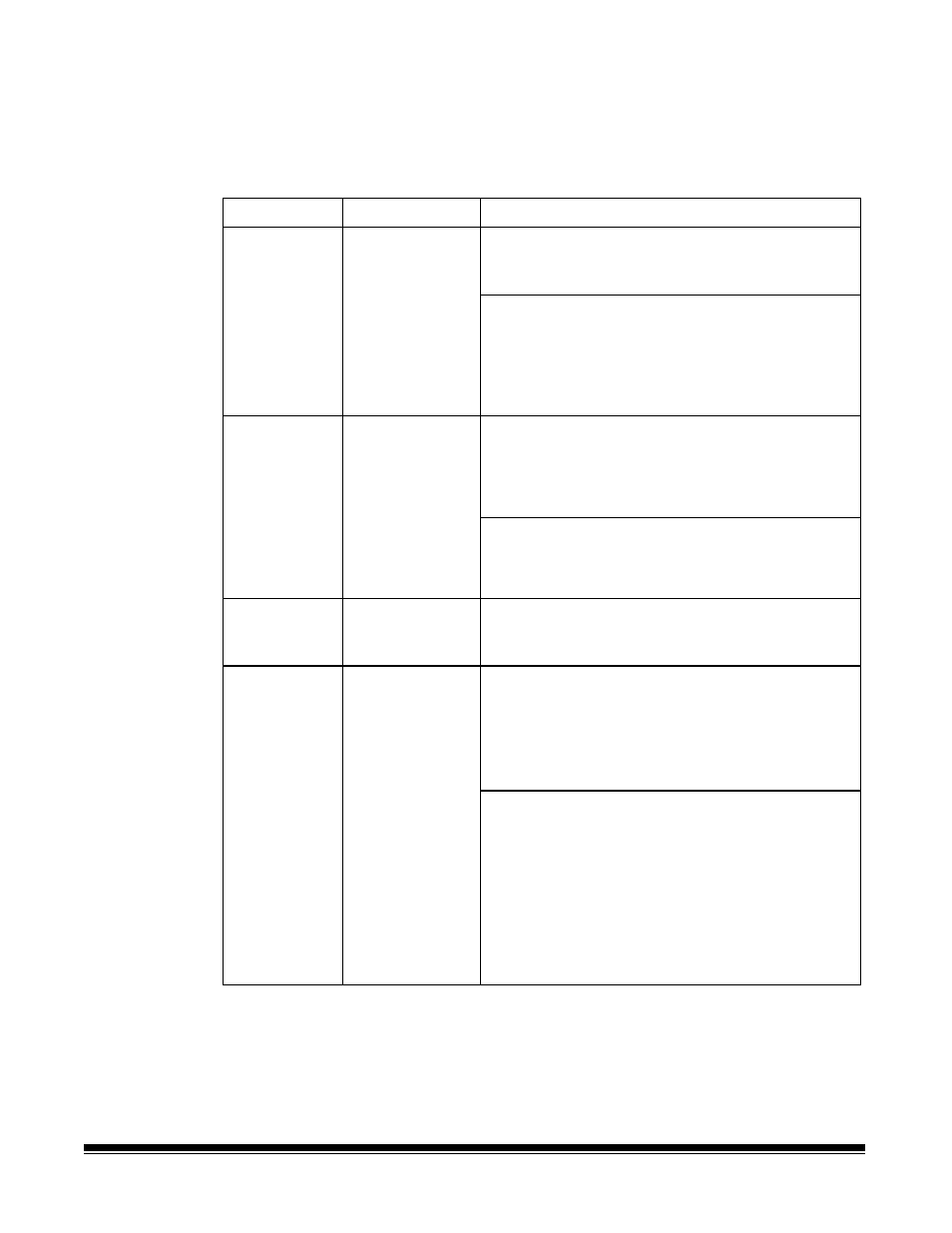

Table 2 — Common Causes of Low Bar Code Ratings

Field

Problem Type

Cause

W/N

NEW

Dimensional

Bar codes not printed according to

specifications (refer to Kodak publication Bar

Code Made Easy, A-61099).

Inaccurate measurements due to:

•

Ink smearing (improper curing)

•

Ink spreading (use of super-absorbent

paper)

•

Use of dot matrix printers (ragged edges)

RMIN

CONTRAST

Reflectance

Bar elements are too light often caused by:

•

Use of old ink ribbon

•

Hammer pressure too light

•

Defective/dirty print head

Space elements are too dark often caused by:

•

Dark colored paper background

•

Stain on paper

MOD

Reflectance

Bar code element edges are ragged rather than

straight often caused by use of a dot matrix

printer.

DEFECT

Reflectance

Bar elements contain voids (white spots) often

caused by:

•

Use of old ink ribbon

•

Hammer pressure too light

•

Defective/dirty print head

Space elements contain dark spots often

caused by:

•

Paper with flecks

•

Ink smearing (improper curing)

•

Ink spreading (use of super-absorbent

paper)

•

Defective/dirty print head

•

Toner contamination (if using a laser printer)

Upon completion of the test:

•

Remove the bar code from the imaging guide.

•

Press C to return to normal operation, or press Stop to remain in the

test environment.