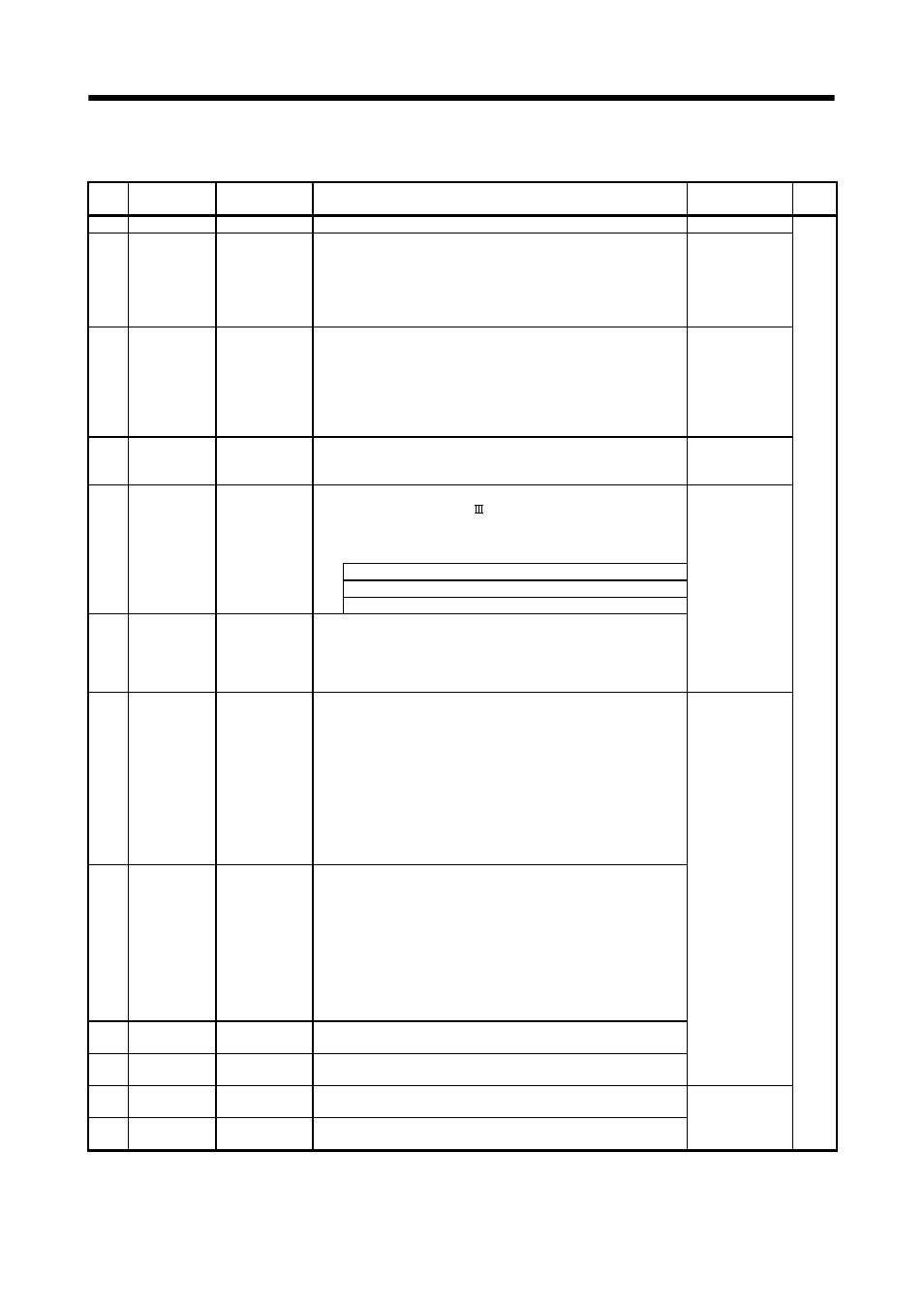

Appendices, Table 1.2 special register list (continued), App - 9 – MITSUBISHI ELECTRIC MOTION CONTROLLERS Q172DCPU User Manual

Page 144

APP - 9

APPENDICES

Table 1.2 Special register list (Continued)

No. Name

Meaning

Details

Set by

(When set)

Remark

SD395 Multiple CPU No. Multiple CPU No.

• CPU No. of the self CPU is stored.

S (Initial processing)

SD500

SD501

Real mode axis

information

register

Real mode axis

information register

• The information (Real mode axis: 0/Except real mode axis: 1) used as a real

mode axis at the time of switching from real mode to virtual mode is stored.

SD500 : b0 to b15 (Axis 1 to 16)

SD501 : b0 to b15 (Axis 17 to 32)

• The real mode axis information does not change at the time of switching from

virtual mode to real mode

S (At virtual mode

transition)

SD502

SD503

Servo amplifier

loading

information

Servo amplifier

loading information

• The loading status (loading: 1/non-loading: 0) of the servo amplifier checked

in initial process, and stored as the bit data.

SD502 : b0 to b15 (Axis 1 to 16)

SD503 : b0 to b15 (Axis 17 to 32)

• The axis which turned from non-loading to loading status after power-on is

handled as loaded. (However, the axis which turned from loading to non-

loading status remains as loaded.)

S (Initial processing)

SD504

SD505

SD506

Real mode/virtual

mode switching

error information

Real mode /virtual

mode switching

error code

• When a mode switching error occurs in real-to-virtual or virtual-to-real

mode switching, or a mode continuation error occurs in the virtual mode, its

error information is stored.

S (Occur an error)

• This signal is used to temporarily suspend SSCNET communication while

servo amplifiers and/or SSCNET

cables after Axis 1 are exchanged with the

power supply ON in a Multiple CPU system.

SD508 stores the command status for "accept waiting" or "execute waiting"

during this process.

0 : Connect/disconnect command accept waiting

-1 : Connect/disconnect execute waiting

SD508

Connect/

Disconnect

(Status)

Connect/

disconnect of

SSCNET

-2

Connect/disconnect

executing

SD510

SD511

Test mode

request error

It is operating in

requirement error

occurrence of the

test mode, axis

information

• Each axis is stopping: 0/Operating: 1, information is stored as a bit data.

SD510 : b0 to b15 (Axis 1 to Axis 16)

SD511 : b0 to b15 (Axis 17 to Axis 32)

S (Main processing)

SD512

Motion CPU

WDT error cause

Error meaning of

WDT error occurs

• The following error codes are stored in SD512.

1: S/W fault 1

2: Operation cycle over

3:

Q

bus

WDT

error

4:

WDT

error

201 to 215: Q bus H/W fault

250 to 253: Servo amplifier interface H/W fault

300: S/W fault 3

301: 15 CPSTART instructions of 8 or more points were started

simultaneously.

303: S/W fault 4

SD513

SD514

SD515

Manual pulse

generator axis

setting error

Manual pulse

generator axis

setting error

information

• Contents of the manual pulse generator axis setting error is stored when the

manual pulse generator axis setting error flag (SM513) turn on.

(Normal: 0/Setting error: 1)

SD513 : The manual pulse generator axis setting error is stored in b0 to b2

(P1 to P3).

The smoothing magnification setting is stored in b3 to b5 (P1 to P3).

SD514 : One pulse input magnification setting error is stored in b0 to b15

(axis 1 to axis 16).

SD515 : One pulse input magnification setting error is stored in b0 to b15

(axis 17 to axis 32).

SD516

Error program

No.

Error program No.

of servo program

• When the servo program setting error flag (SM516) turns on, the erroneous

servo program No. will be stored.

SD517

Error item

information

Error code of servo

program

• When the servo program setting error flag (SM516) turns on, the error code

corresponding to the erroneous setting item will be stored.

S (Occur an error)

SD520 Scan time

Scan time

(1ms units)

• Main cycle is stored in the unit 1ms.

Setting range (0 to 65535[ms])

SD521

Maximum scan

time

Maximum scan

time (1ms units)

• The maximum value of the main cycle is stored in the unit 1ms.

Setting range (0 to 65535[ms])

S (Main processing)