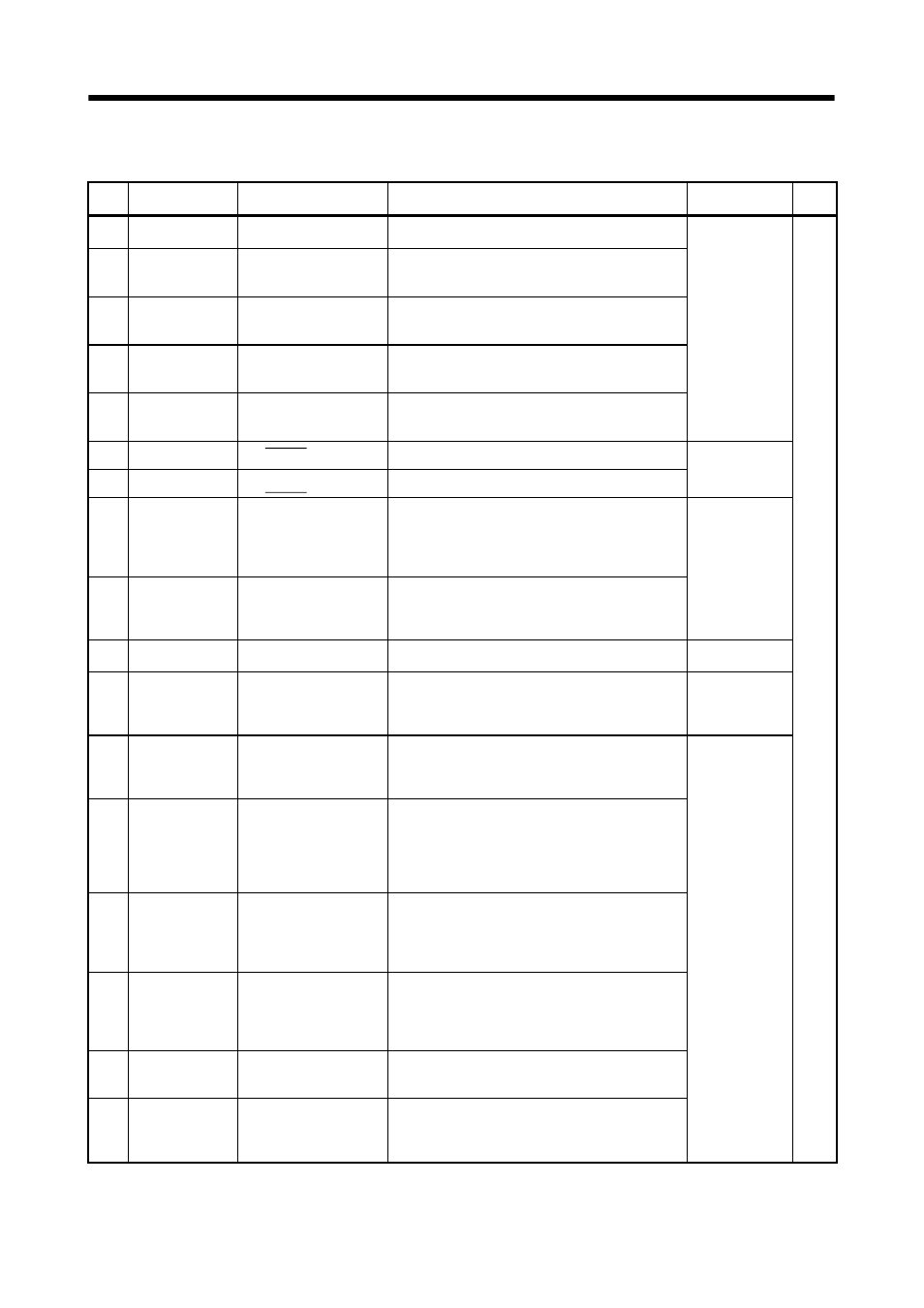

Appendices, Table 1.1 special relay list (continued), App - 3 – MITSUBISHI ELECTRIC MOTION CONTROLLERS Q172DCPU User Manual

Page 138

APP - 3

APPENDICES

Table 1.1 Special relay list (Continued)

No. Name

Meaning

Details

Set by

(When set)

Remark

SM243 No.4 CPU resetting

OFF : CPU No.4 reset cancel

ON : CPU No.4 resetting

• Goes OFF when reset of the CPU No.4 is cancelled.

SM244 No.1 CPU error

OFF : CPU No.1 normal

ON : CPU No.1 during stop

error

• Goes OFF when the CPU No.1 is normal. (Including a

continuation error)

• Comes ON when the CPU No.1 is during stop error.

(Note-2)

SM245 No.2 CPU error

OFF : CPU No.2 normal

ON : CPU No.2 during stop

error

• Goes OFF when the CPU No.2 is normal. (Including a

continuation error)

• Comes ON when the CPU No.2 is during stop error.

(Note-2)

SM246 No.3 CPU error

OFF : CPU No.3 normal

ON : CPU No.4 during stop

error

• Goes OFF when the CPU No.3 is normal. (Including a

continuation error)

• Comes ON when the CPU No.3 is during stop error.

(Note-2)

SM247 No.4 CPU error

OFF : CPU No.4 normal

ON : CPU No.4 during stop

error

• Goes OFF when the CPU No.4 is normal. (Including a

continuation error)

• Comes ON when the CPU No.4 is during stop error.

(Note-2)

S (Change status)

SM400 Always ON

ON

OFF

• Normally is ON.

SM401 Always OFF

ON

OFF

• Normally is OFF.

S (Main processing)

SM500

PCPU READY

complete

ON : PCPU READY

completion

OFF : PCPU READY

incompletion

• When the PLC ready flag (M2000) turn OFF to ON, the

fixed parameters, servo parameters and limit switch output

data, etc., are checked, and if no error is detected, this flag

turns ON.

• Turn OFF with PLC ready flag (M2000) OFF.

SM501 Test mode ON

ON : TEST mode ON

OFF : Except TEST mode

• Judge whether TEST mode ON or not using MT Developer.

• If the TEST mode is not established by TEST mode request

using MT Developer, the TEST mode request error flag

(SM510) turns ON.

S (Request)

SM502

External forced stop

input

ON : Forced stop OFF

OFF : Forced stop ON

• Confirm forced stop ON/OFF.

S (Operation cycle)

SM503

Digital oscilloscope

executing

ON : Digital oscilloscope is

stop

OFF : Digital oscilloscope is

executing

• Confirm the execution of digital oscilloscope using MT

Developer.

S (Change status)

SM510

TEST mode request

error

ON :

Abnormal

OFF : Normal

• Turn ON if the TEST mode is not established by TEST mode

request using MT Developer.

• When this relay is ON, the error content is stored in the

TEST mode request error register (SD510, SD511).

SM512

Motion CPU WDT

error

ON :

Abnormal

OFF : Normal

• Turn ON when a "watchdog timer error" is detected by the

Motion CPU self-diagnosis function.

When the Motion CPU detects a WDT error, it executes an

immediate stop without deceleration of the operating axes.

• The error cause is stored in the "Motion CPU WDT error

cause (SD512)".

SM513

Manual pulse

generator axis setting

error

ON : At least one D714 to

D719 setting is

abnormal.

OFF : All D714 to D719

settings are normal.

• Judge whether normal/abnormal of the register for manual

pulse generator axis setting register (D714 to D719).

• When this relay is ON, the error content is stored in the

manual pulse generator axis setting error register (SD513

to SD515).

SM516

Servo program

setting error

ON :

Abnormal

OFF : Normal

• Judge whether normal/abnormal of the positioning data of

servo program(K) specified with the Motion SFC program,

and if error is detected this flag turns ON.

• The content of a servo program setting error is stored at

SD516, SD517.

SM526

Over heat warning

latch

OFF : Normal

ON :

Abnormal

• Turn ON when the temperature of Motion CPU module

becomes specified value 85[°C] (185[°F]) or more.

Remains ON even if normal status is restored.

SM527 Over heat warning

OFF : Normal

ON :

Abnormal

• Turn ON when the temperature of Motion CPU module

becomes specified value 85[°C] (185[°F]) or more.

Turn OFF when the temperature of Motion CPU module

returns to normal.

S (Occur an error)