InFocus Laser Platform M-300 User Manual

Page 81

Sample Materials

6-17

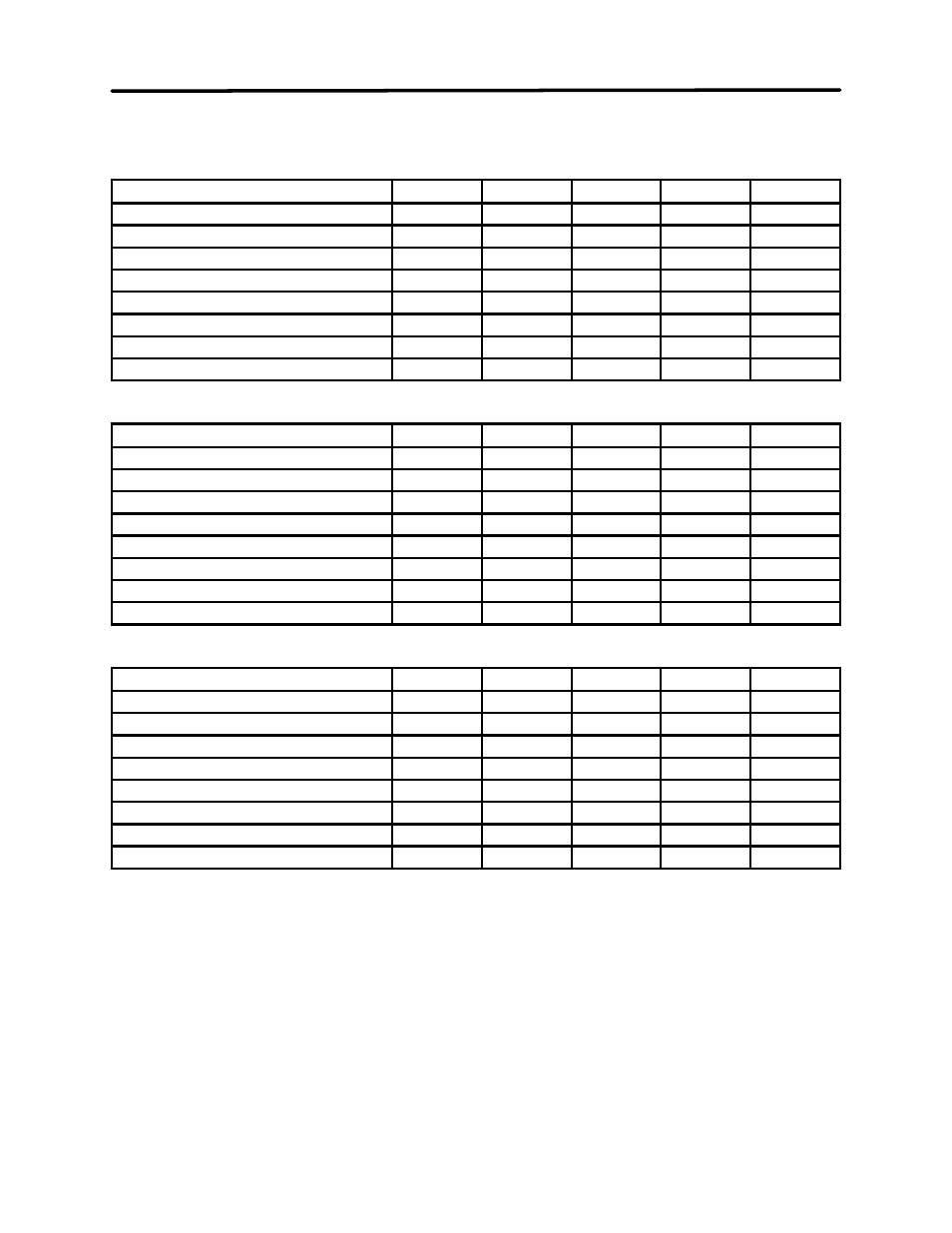

MELAMINE - STANDARD ENGRAVING

LIGHT RASTER ENGRAVING

LASER WATTAGE

POWER

SPEED

PPI

PASS

DEPTH

15

100

20

500

1

.015”

20

100

27

500

1

.015”

25

100

33

500

1

.015”

30

100

40

500

1

.015”

35

100

47

500

1

.015”

40

100

53

500

1

.015”

45

100

60

500

1

.015”

50

100

67

500

1

.015”

DEEP RASTER ENGRAVING

LASER WATTAGE

POWER

SPEED

PPI

PASS

DEPTH

15

100

14

500

1

.020”

20

100

19

500

1

.020”

25

100

23

500

1

.020”

30

100

28

500

1

.020”

35

100

33

500

1

.020”

40

100

37

500

1

.020”

45

100

42

500

1

.020”

50

100

47

500

1

.020”

VECTOR ENGRAVING

LASER WATTAGE

POWER

SPEED

PPI

PASS

DEPTH

15

40

4.0

500

1

.010”

20

30

4.0

500

1

.010”

25

24

4.0

500

1

.010”

30

20

4.0

500

1

.010”

35

17

4.0

500

1

.010”

40

15

4.0

500

1

.010”

45

13

4.0

500

1

.010”

50

12

4.0

500

1

.010”

COMMENTS

Engraving melamine is very similar to engraving regular wood with the added benefit of a

consistent surface finish and uniform base material composition. Unlike regular wood that has

grain patterns and density variations, melamine, when laser engraved, produces a flat and even

engraved area. This characteristic gives this material superior engraving and paint filling

qualities. Masking can be used if desired but it is just as easy to spray the engraved area with

water and wipe down with a chamois cloth to remove the smoke residue. Since the top surface

material is consistent in texture and color, engraving photographs or highly detailed images

produces exceptional results. Refer to the next example on engraving photographs and/or

ClipArt.