InFocus Laser Platform M-300 User Manual

Page 80

6-16

Sample Materials

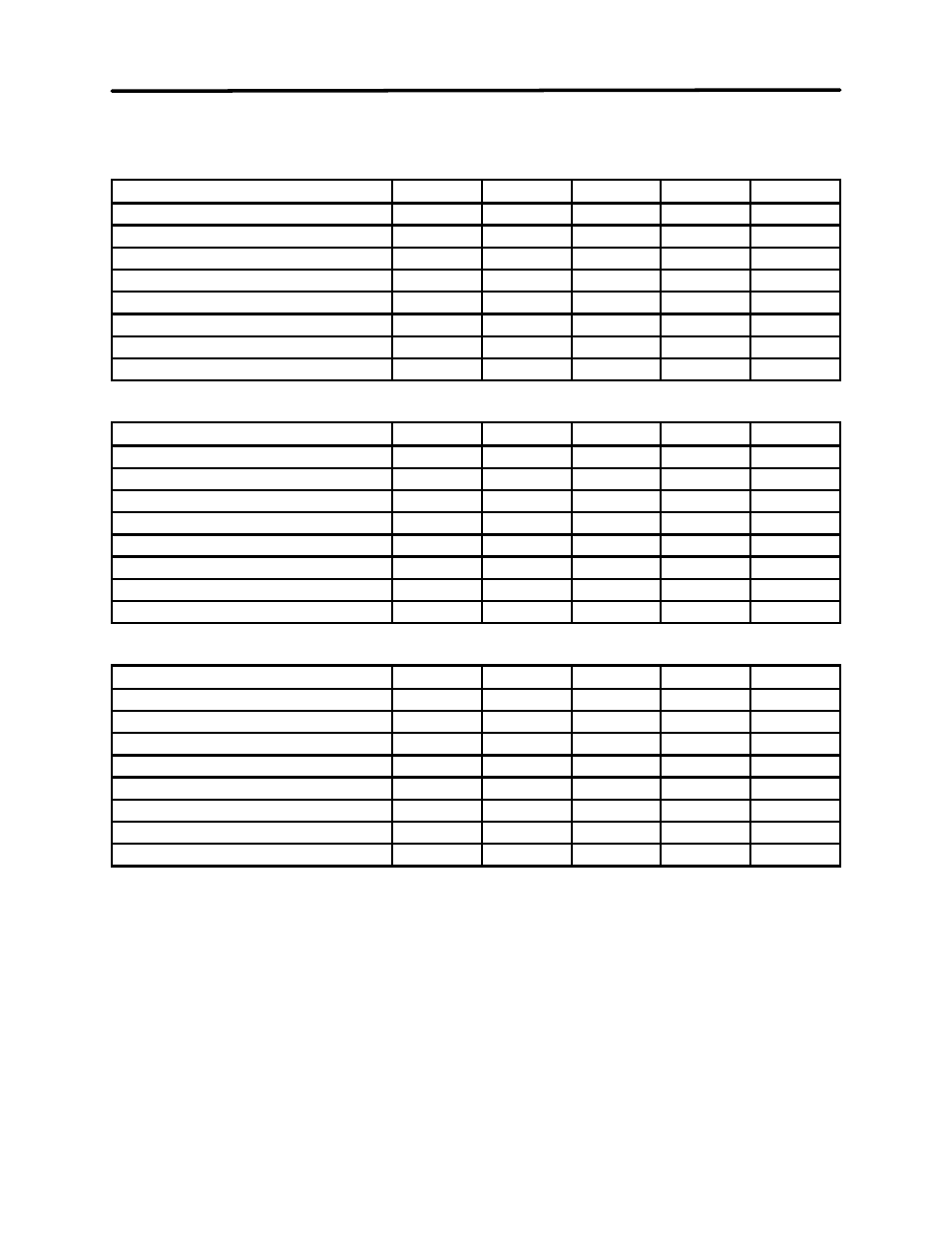

MAT BOAR D

RASTER ENGRAVING

LASER WATTAGE

POWER

SPEED

PPI

PASS

DEPTH

15

90

80

250

1

.005”

20

68

80

250

1

.005”

25

54

80

250

1

.005”

30

45

80

250

1

.005”

35

39

80

250

1

.005”

40

34

80

250

1

.005”

45

30

80

250

1

.005”

50

27

80

250

1

.005”

VECTOR ENGRAVING

LASER WATTAGE

POWER

SPEED

PPI

PASS

DEPTH

15

40

4.0

250

1

.005”

20

30

4.0

250

1

.005”

25

24

4.0

250

1

.005”

30

20

4.0

250

1

.005”

35

17

4.0

250

1

.005”

40

15

4.0

250

1

.005”

45

13

4.0

250

1

.005”

50

12

4.0

250

1

.005”

VECTOR CUTTING

LASER WATTAGE

POWER

SPEED

PPI

PASS

DEPTH

15

100

3.2

200

1

.050”

20

75

3.2

200

1

.050”

25

60

3.2

200

1

.050”

30

50

3.2

200

1

.050”

35

43

3.2

200

1

.050”

40

38

3.2

200

1

.050”

45

33

3.2

200

1

.050”

50

30

3.2

200

1

.050”

COMMENTS

Mat board (thick cardboard) is an excellent material to use for architectural modeling and for

picture framing. It cuts and engraves very neatly and cleanly. It comes in a variety of shades

and colors. Patterns can be engraved on the surface with a power setting for light engraving

which just breaks through the very thin top layer and exposes the lighter colored underlying

substrate. When engraving, a low PPI setting is used to prevent overexposure of the underlying

substrate material, which causes excessive dark discoloration. Masking is not necessary on the

top surface when engraving. When cutting, both sides might need to be masked and the

material elevated above the engraving table. This will produce an extremely clean edge on both

sides of the material.