InFocus Laser Platform M-300 User Manual

Page 71

Sample Materials

6-7

COMMENTS

Engraving mirrored acrylic is similar to engraving regular acrylic. The idea is to engrave through

the mirrored backing enough to begin to penetrate into the acrylic. Engraving deeply will cause a

crusty residue to form just like with non-mirrored acrylic. A double image will appear if engraving

on the front side of the mirror. It is not necessary to mask the backside when engraving

because the mirrored backing shields the acrylic from smoke damage. To cut mirrored acrylic,

it might be necessary to remove all original masking, re-mask with transfer tape, and dampen

the tape with water from a spray bottle. Next, place the acrylic in the laser with the mirrored

surface facing upwards and elevate at least 1/2 inch above the table. The laser beam will not

reflect off of the mirrored surface because it is absorbed by the acrylic first. Sometimes cutting

the acrylic from the backside will cause the mirrored backing to distort and crack from the

intense heat required to cut. If the combination of engraving and cutting is desired, our

suggestion is to engrave the backing, unmasked, remove the acrylic, mask both sides with

transfer tape, flip the acrylic over, dampen, elevate, re-focus, and cut from the front side. When

paint filling the engraved area, make sure to use an acrylic-based paint or paint that does not

contain acetone or alcohol, as these chemicals will crack the acrylic. Water based paints also

work very well. Since the mirrored backing serves as a masking, it is not necessary to mask the

backside before engraving.

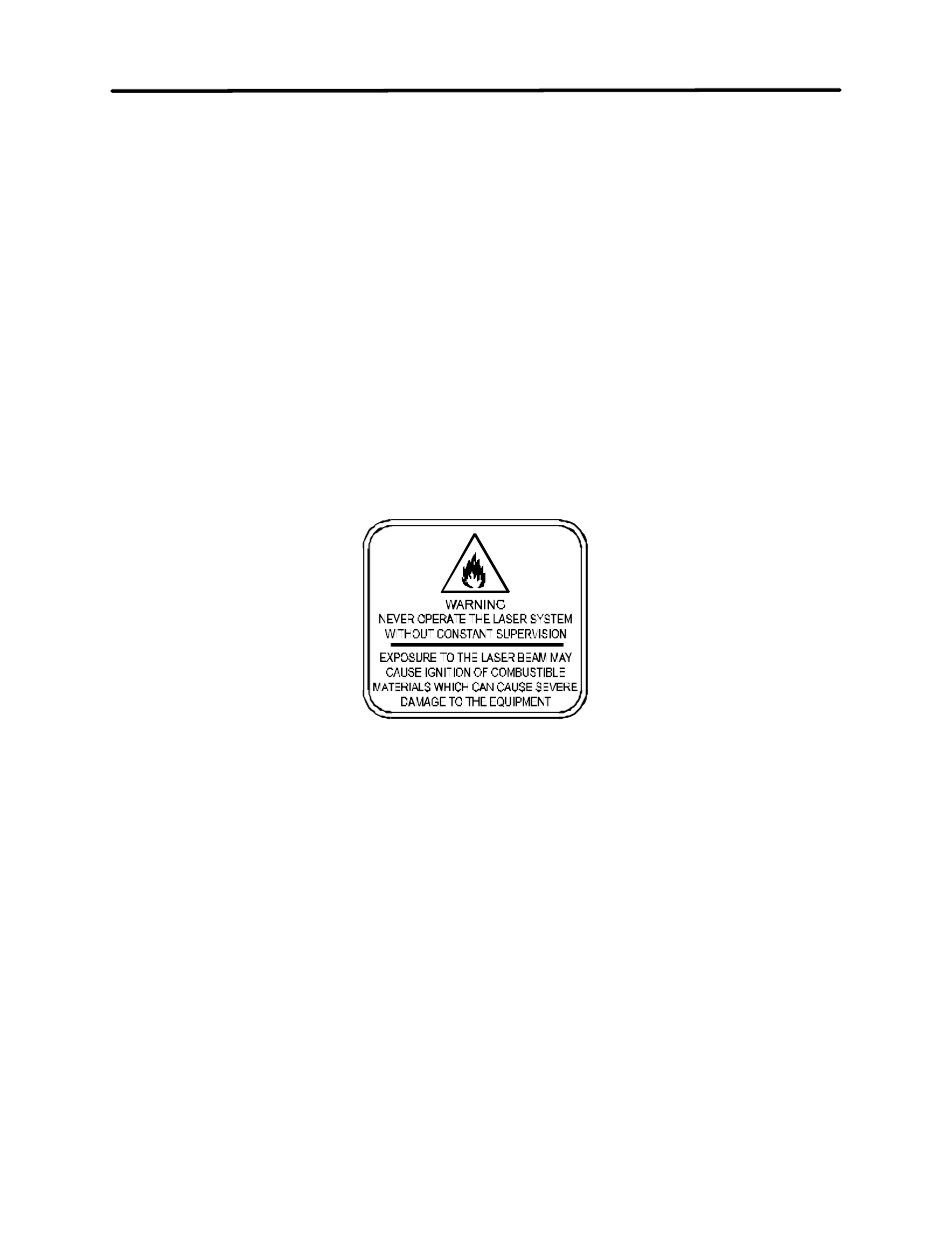

Acrylic is extremely flammable. Do not leave the laser system unattended when cutting

or engraving.