F. factory-built fireplace installation – Harman Stove Company P35I User Manual

Page 11

11

Pellets or Corn/Pellet Mixture Only

P35i Fireplace Insert

Save These Instructions

3-90-775R15_04/13

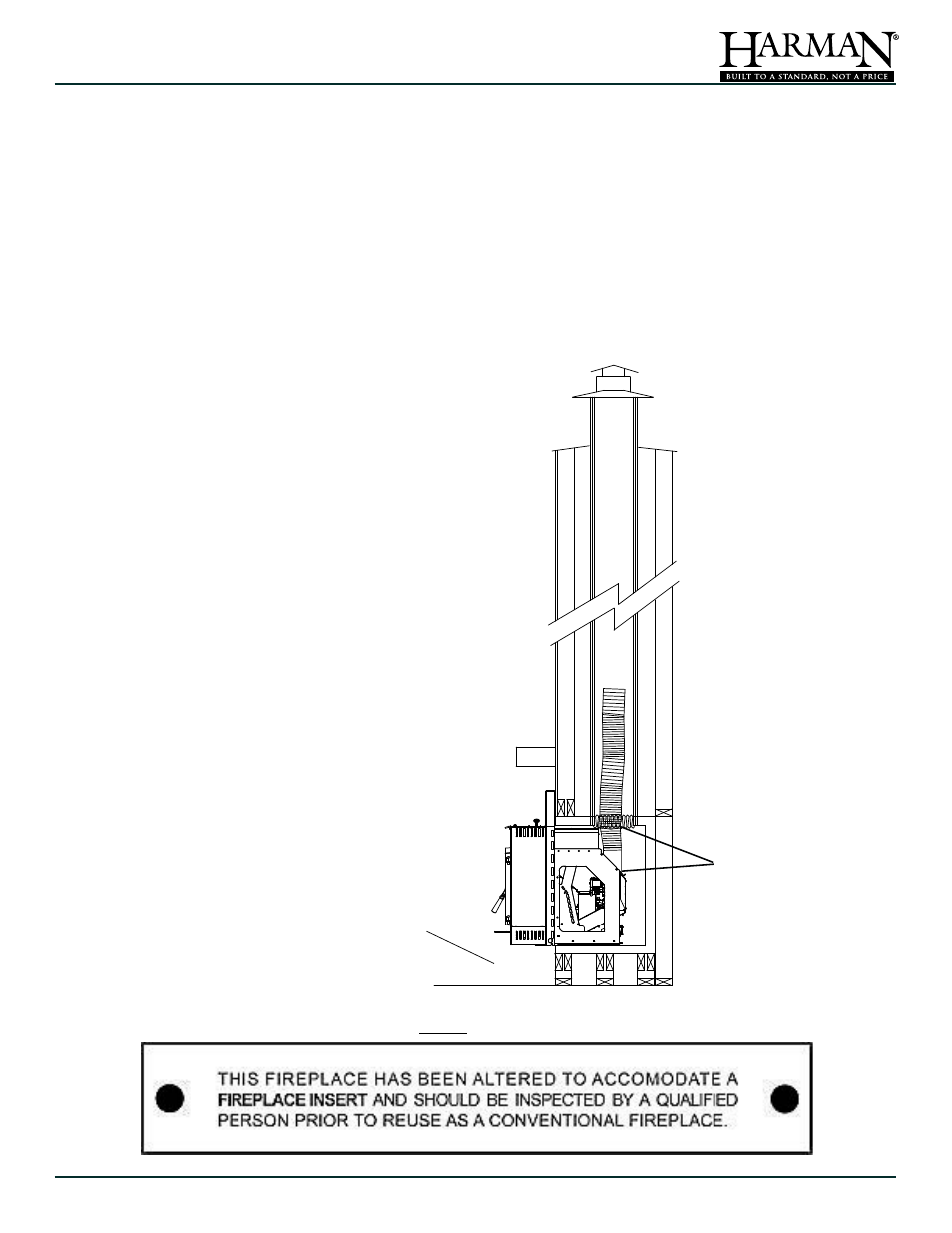

F. Factory-Built Fireplace

Installation

When installing the P35i Insert into a factory built wood

burning fireplace, several things need to be taken into

consideration.

The size of the fireplace opening. Will the unit fit into

the opening? Some of the factory built fireplaces have

metal smoke shields inside the top that can be removed

to gain height. Keep in mind that anything removed

from the factory built fireplace must be attached to the

fireplace with a metal wire.

Floor protection guidelines,

as listed previously, must also be followed.

The manufactured fireplace may not be altered beyond

the exceptions listed below. Never remove masonry

bricks or mortar from an existing fireplace.

The following modifications are permissible:

• Removal of the damper or lock in open position

• Removal of smoke shelf or baffle

• Removal of andirons or ember catchers

• Removal of log grate

• Removal of view screen or curtain

• Removal of doors

• External trim pieces, that do not affect the operation

of the fireplace, may be removed providing they can

be stored on or within the fireplace for reassembly

if the insert is removed.

• If the hearth extension is lower than the fireplace

opening, the portion of the insert extending onto the

hearth must be supported.

• Final approval of this type of installation is contingent

upon the authority having jurisdiction.

Note: If the Harman® P35i Insert is installed into a factory built wood burning fireplace, this

label (Harman® part # 3-90-00675) MUST be attached to the altered fireplace.

The factory built chimney must be listed per UL 127 (US)

and meet type HT requirements of UL 103 (US). Factory

Built fireplace chimneys tested to UL 127-98 may be, at the

fireplace manufacturers option, tested to the same criteria

as UL 103HT requirements. If the chimney is not listed as

meeting HT requirements, or if the factory built fireplace was

tested prior to 1998, a full height listed chimney liner must be

installed from the appliance flue collar to the chimney top.

Liner must meet high temperature (2100 F) per UL1777 (US).

The liner must be securely attached to both the flue collar

and the chimney cap. To prevent room air passage to the

chimney cavity of the fireplace, seal the damper area around

the chimney liner with fiberglass batting.

Hearth must be constructed to

the proper height and finished

with a non-combustible

material.

IN CANADA: This fireplace insert

must be installed with a continuous

chimney liner of a minimum 3"

diameter extending from the insert to

the top of the chimney. The chimney

liner must conform to the Class 3

requirements of CAN/ULC-S635,

Standard for Lining Systems for

Existing Masonry or Factory Built

Chimneys and Vents, or CAN/ULC-

S640, Standard for Lining Systems

for New Masonry Chimneys.

When using single-wall

venting or flex,this section

of venting must be wrapped

with a non-combustible

insulation to prevent excess

temperatures within the

fireplace and on the fuel

hopper.