Contact spring replacement (conventional method) – HP 2040D User Manual

Page 66

Series 2040 Test System

Series 2040 Maintenance Manual V2.00

Module Repair and Replacement

65

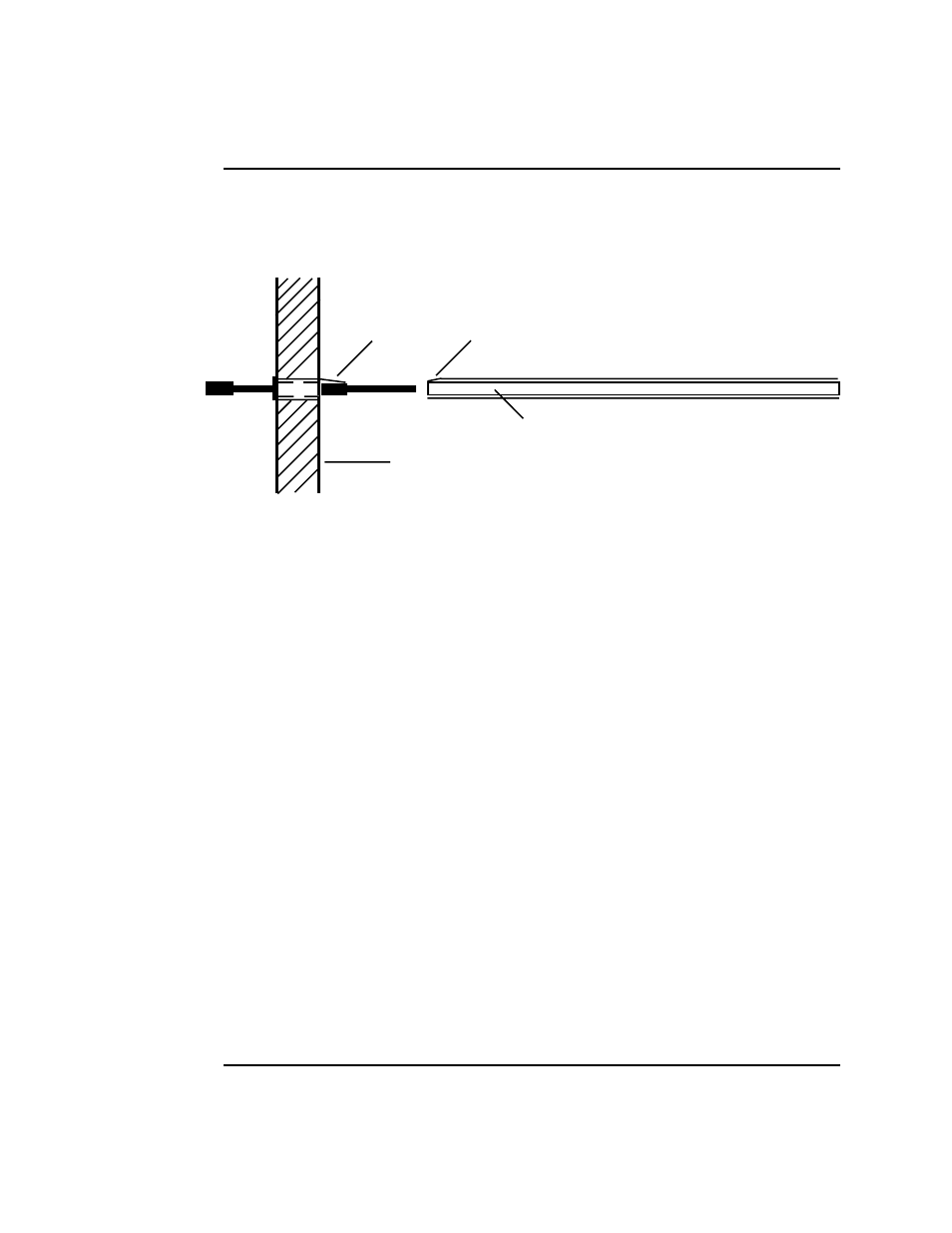

Plunger

Patchboard

“D” shaped sleeve

“D”shaped

latching tab

Board Side of Patchboard

Retract the plunger of the spring removal tool and position the sleeve of the

tool so that the flat side of the “D”-shape formed by the end of the sleeve is

aligned with the latching tab of the damaged Patchboard spring (Testhead card

side of the Patchboard). Carefully lower the sleeve over the spring until it is

fully seated and the sleeve is resting against the Patchboard. The “stinger” of

the spring will slide into the hollow end of the plunger. A flashlight may be

needed to provide adequate lighting, especially if there are Testhead cards on

either side of the slot. The latching tab of the spring should be fully depressed

inside the tool sleeve.

Be sure that the tool is held straight in-line with the spring. Apply steady,

careful pressure on the handle. Do NOT push sharply and do NOT strike or

tap the end of the handle. Resistance will be felt as the spring slides out of the

Patchboard. Continue to apply steady pressure until the plunger handle

bottoms out. If these precautions are ignored, it is possible to damage the tool

or the Patchboard material itself.

The ejected Patchboard spring will be protruding from the top (fixture mating)

side of the Patchboard. Simply grasp it and pull it free of the Patchboard.

After replacing the spring in the Patchboard, re-install the Testhead card and

close the Testhead.

CONTACT SPRING REPLACEMENT (Conventional Method)

To remove a damaged contact spring when the removal tool is not available,

use the following procedure: