E-z seal® sealing solution maintenance, E-z seal® sealing solution maintenance -4, E-z seal – Pitney Bowes DM550 Series User Manual

Page 140: Sealing solution maintenance

9 • Maintaining and Updating

9 - 4

SV61436 Rev. D

3. Drop the new tape in so that

it feeds from the bottom of

the roll to the right.

The protective backing on

the tape should be facing

down. Pull about 10 inches

of tape from the end of the

roll up toward the cover and

then loop it down into the

slot.

4. From the “Out of Tape” or “Load Tape” screen, select Load Tape. Feed

the tape into the slot while the tape motor is running. The machine

automactically cuts off the excess tape.

5. Close the feed cover.

Tape has run out

1. If the system actually runs out of tape, the “Out of Tape” screen

appears.

2. Open the cover and select Unload Tape from the “Out of Tape” screen.

3. Remove any remaining tape on the tape roll. Follow steps 2 - 4 in the

Tape still on roll

procedure above.

E-Z Seal

®

Sealing

Solution

Maintenance

Your mailing system displays a message telling you when your E-Z Seal®

Solution is running low. When you receive this message, your system can

still seal approximately 50 envelopes.

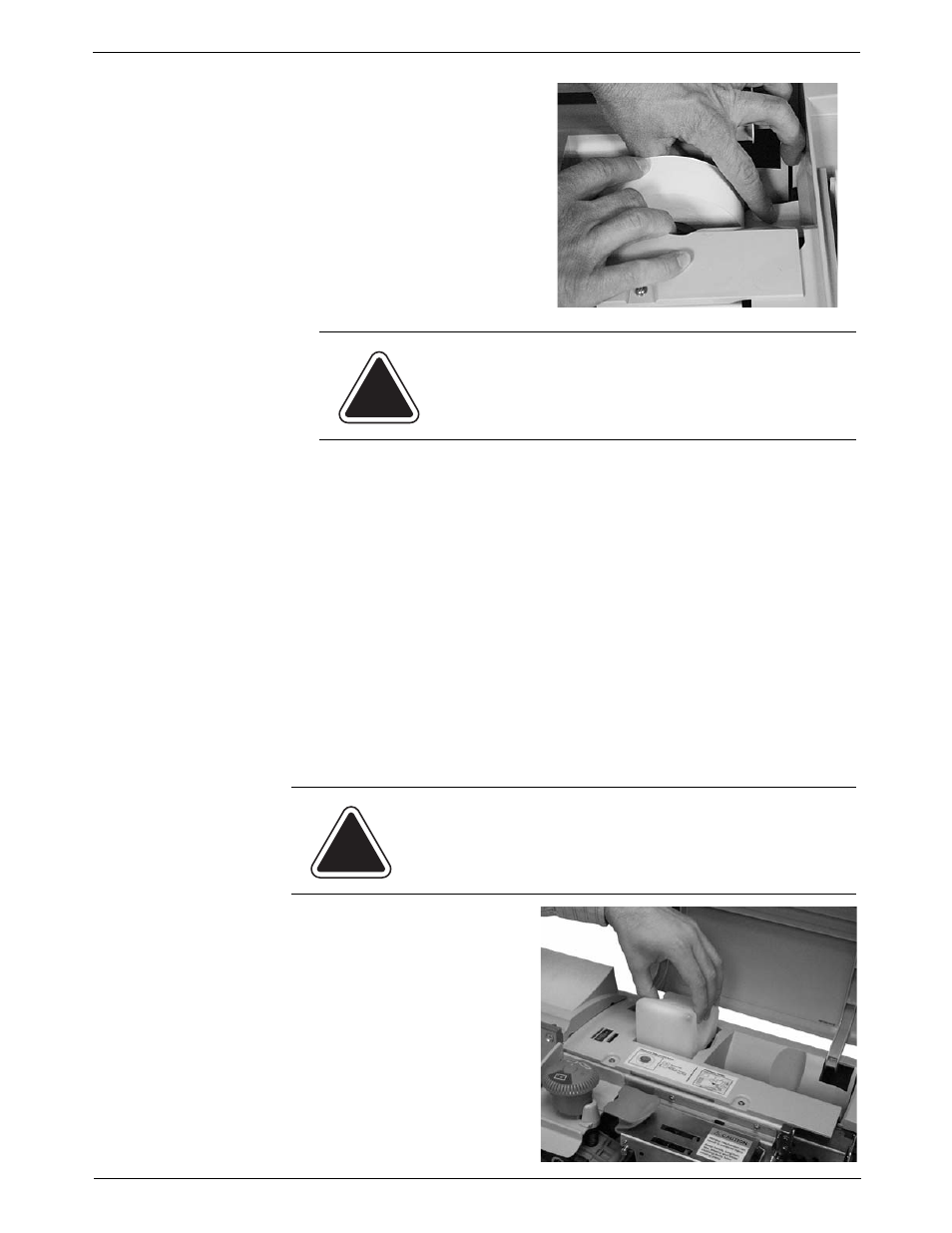

1. Open the feed cover and lift

out the E-Z Seal® bottle.The

bottle is located to the left of

the tape roll.

CAUTION:

Do not load a tape strip that has any pink or

black stripes showing. This will cause the last piece of

tape to jam in the machine which and you will need to

place a service call.

CAUTION:

Pitney Bowes recommends using E-Z Seal®

Solution because it helps keep your moistener tank clean and

improves sealing efficiency. To order E-Z Seal® Solution,

refer to Chapter 11, Supplies and Options in this guide.