Installation – Parr Instrument 6400 User Manual

Page 7

6400

Calorimeter Instruction Manual

2-1

INSTALLATION

Note:

Some of the following manual sections contain information in the form of

warnings, cautions and notes that require special attention. Read and

follow these instructions carefully to avoid personal injury and damage to

the instrument. Only personnel qualified to do so, should conduct the

installation tasks described in this portion of the manual.

Each Parr 6400 Calorimeter was completely assembled and thoroughly tested prior to

shipment. Unpack the calorimeter and carefully check the individual parts against the

packing list. If shipping damage is discovered, save the packing cartons and report it

immediately to the delivering carrier.

This apparatus is to be used indoors. It requires at least 4 square feet of workspace on a

sturdy bench or table in a well-ventilated area with convenient access to an electric

outlet, running water and a drain. The supply voltage must be within ± 10% of marked

nominal voltage on the apparatus. The supply voltage receptacle must have an earth

ground connection.

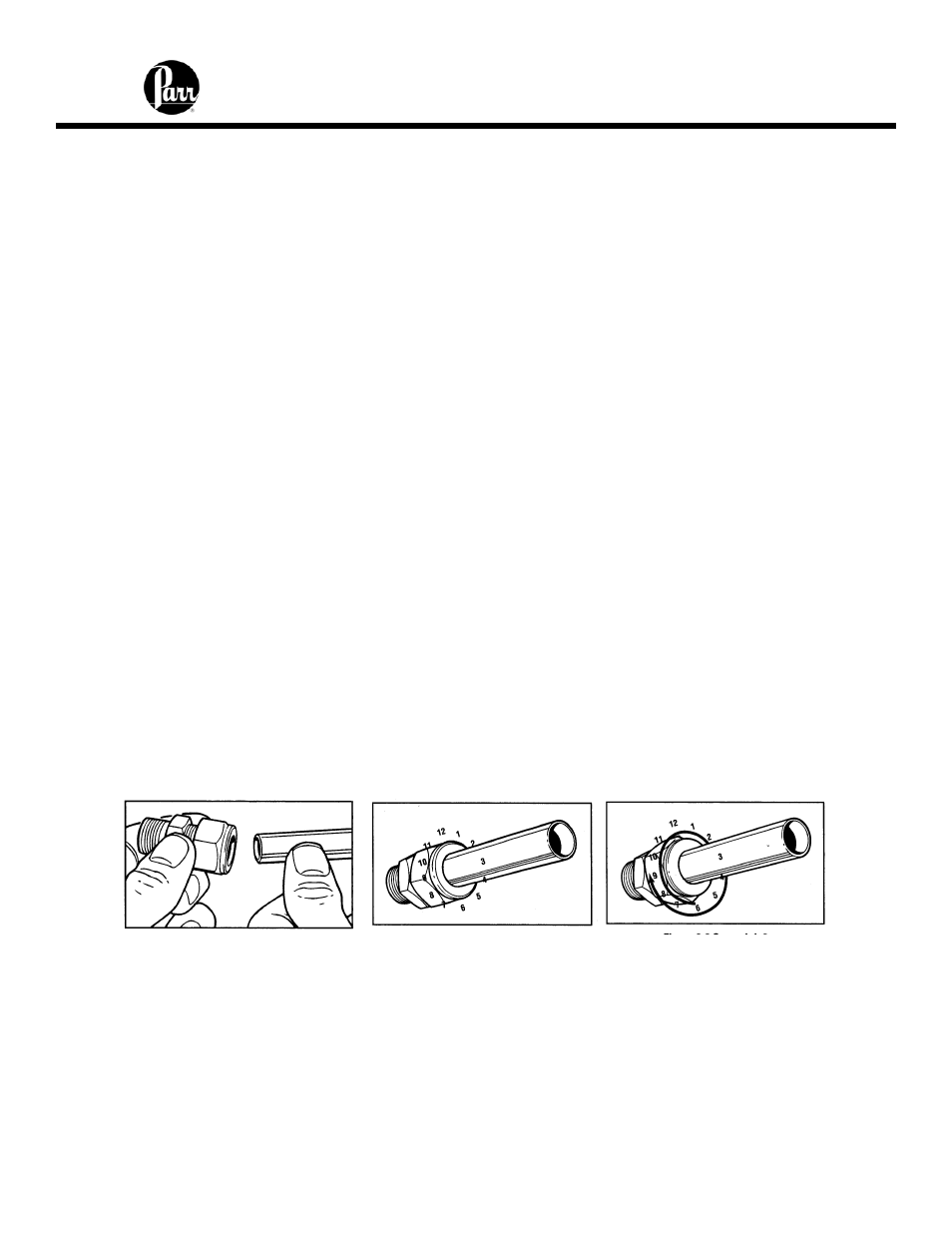

When Swagelok Tube Fittings are used, the instructions for installation are:

1. Simply insert the tubing into the Swagelok Tube Fitting. Make sure that the

tubing rests firmly on the shoulder of the fitting and that the nut is finger-

tight.

2. Before tightening the Swagelok nut, scribe the nut at the 6 o’clock position.

3. While holding the fitting body steady with a back-up wrench, tighten the nut

1-1/4 turns. Watch the scribe mark, make one complete revolution and

continue to the 9 o’clock position.

4. For 3/16" and 4mm or smaller tube fittings, tighten the Swagelok nut 3/4 turns

from finger-tight.

Swagelok tubing connections can be disconnected and retightened many times. The

same reliable leak-proof seal can be obtained every time the connection is remade using

the simple two-step procedure.

1. Insert the tubing with pre-swaged ferrules into the fitting body until the front

ferrule seats.

2. Tighten the nut by hand. Rotate the nut to the original position with a wrench.

An increase in resistance will be encountered at the original position. Then