Parr Instrument 6400 User Manual

Page 24

6400

Calorimeter Instruction Manual

4-5

who intend to test these materials are urged to select the 1138CL Bomb. These bombs

are 250 mL in volume and are rated to a maximum working pressure of

2000 psi. The

bombs are hydrostatically tested to 3000 psi and the sample range is ~1g or 5000 – 8000

calories.

Explosives and High Energy Fuels

Materials which release large volumes of gas which detonate with explosive force or

burn with unusually high energy levels, should not be tested in this calorimeter. Rather,

they should be tested in a model 6100 or 6200 Calorimeter which can be equipped with

an 1104 High Strength Oxygen Bomb designed specifically for these types of samples.

Volatile Sample Holders

Volatile samples are defined as one with an initial boiling point below 180ºC per ASTM

D-2. Volatile samples can be handled in a Parr 43AS Alloy Capsule which has a sturdy

wall with a flat top rim. These holders can be sealed with a disc of plastic adhesive tape

prepared by stretching tape across the top of the cup and trimming the excess with a

sharp knife. The seal obtained after pressing this disc firmly against the rim of the cup

with a flat blade will be adequate for most volatile samples. The tape used for this

purpose should be free of chlorine and as low in sulfur as possible. Borden Mystic Tape,

No. M-169-C or 3M Transparent Tape, No. 610, are recommended for this purpose. The

3M Transparent Tape can be ordered through Parr, Part No. 517A.

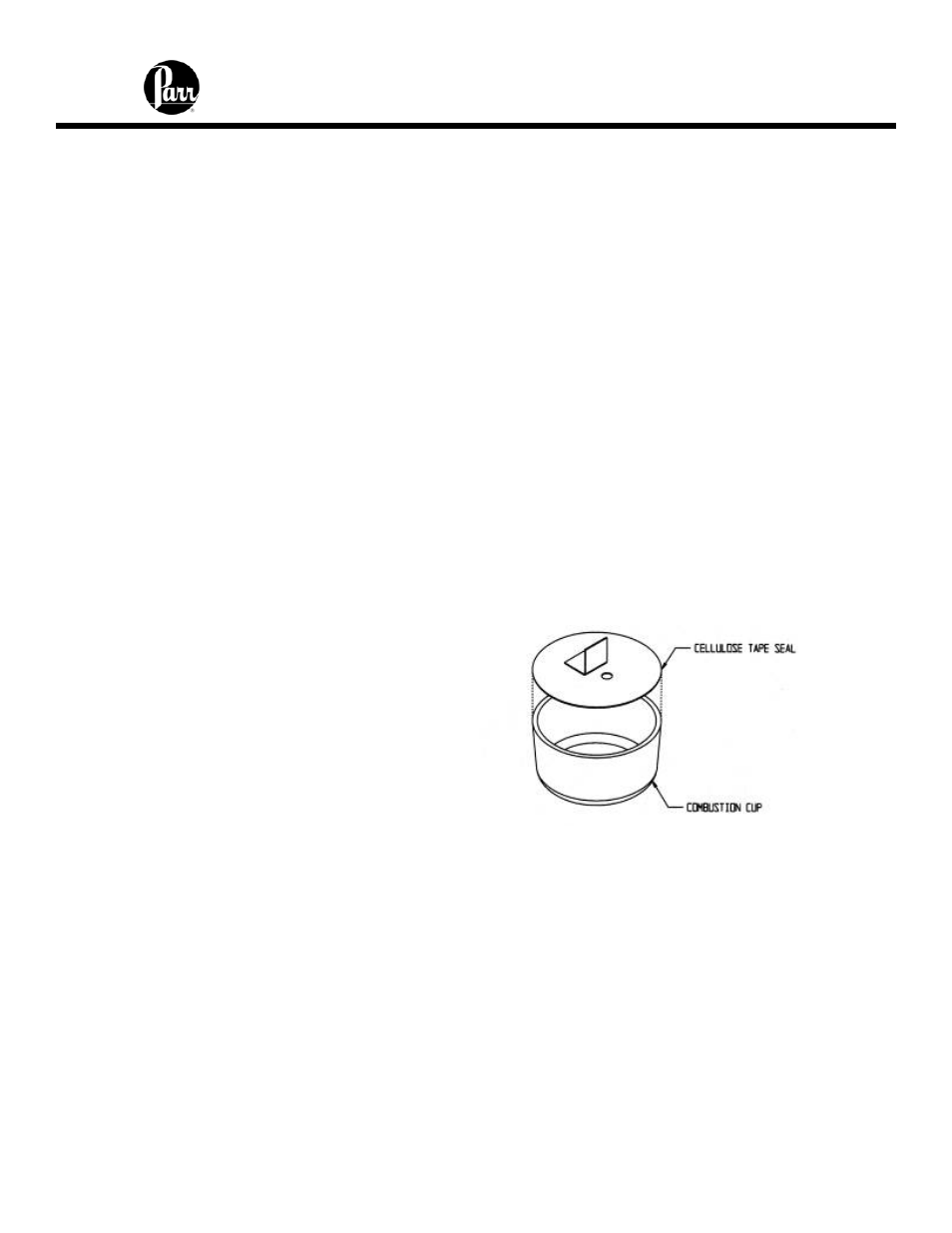

Figure 4 - Volatile Sample Technique

The weight of the tape disc must be

determined separately and a correction

applied for any elements in the tape

which might interfere with the

determination. The approximate Heat of

Combustion of the tape is 6300 cal/g. An

actual amount should be determined by

running a blank test with tape alone using

a sample weighing 1.0 gram. The

compensation for heat of tape may be

done through the spike option; see Spike

Controls, Heat of Combustion of Spike.

Note:

Tape should always be stored in a sealed container to minimize changes in

its moisture and solvent content.

Use the following procedure when filling and handling any of these tape-sealed sample

holders:

1. Weigh the empty cup or capsule; then cover the top with tape, trim with a knife

and press the trimmed edge firmly against the metal rim. Also cut and attach a

small flag to the disc (see Figure 4).

2. Puncture the tape at a point below the flag, then re-weigh the empty cup with its

tape cover.

3. Add the sample with a hypodermic syringe; close the opening with the flag and

re-weigh the filled cup.