Airplane model function descriptions, Aircraft flight trimming chart – HITEC Optic 6 User Manual

Page 21

Airplane Model Function Descriptions

Airplane Model Function Descriptions

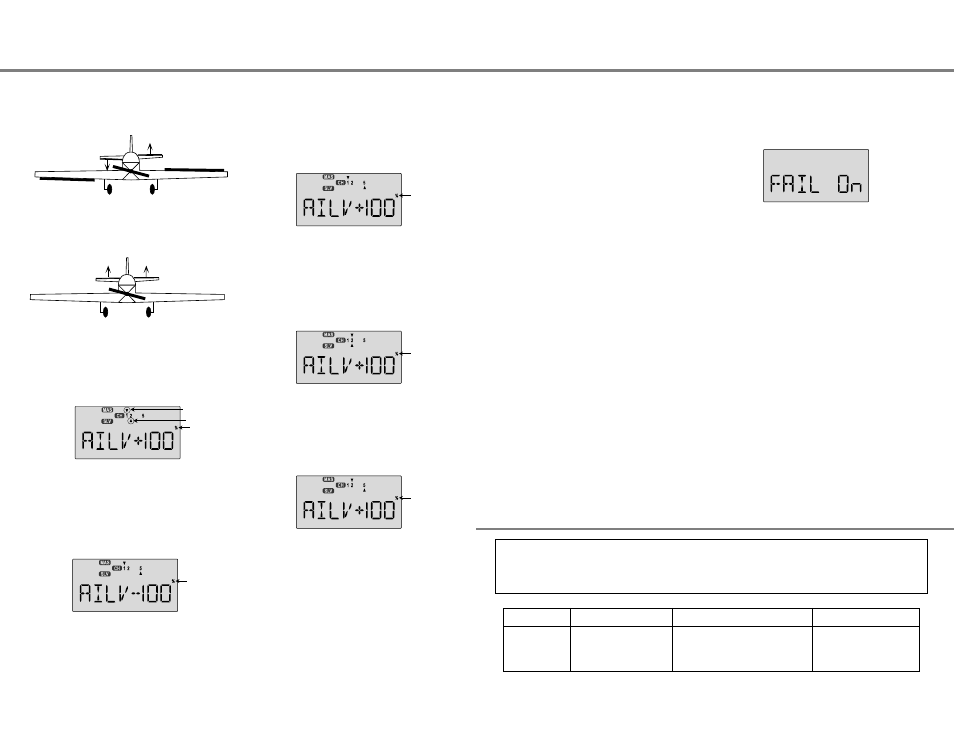

3. Move the stick to command aileron. In addition to the aileron

servo(s), both elevator servos should move. They may move

in opposite directions (as they should) or the same direction

(instructions for correcting this are below).

4. Move the stick to command elevator. Both elevator servos

should move. They may move in the same direction (as

they should) or opposite directions (to be corrected below).

5. Press the Cursor Right key to get to the travel setting

menus. The display shows a triangle over the number 1 and

under the number 2, indicating you are in the AIL->CH2

setting menu, programming the response of the CH2

elevator servo due to aileron (CH1) commands.

6. If the elevator servo plugged into CH2 goes the correct

direction with aileron stick, go to the next step. Otherwise,

press the Data +Increase or -Decrease keys to change the

sign of the percentage displayed. If it is (+), change it to (-),

or vice versa. Only change the sign of the number, you can

decrease its value later if you need to.

7. If the elevator servo plugged into CH5 goes the correct

direction with aileron stick, go to the next step. Otherwise,

press the Cursor Right key to get to the AIL->CH5 setting

menu, then press the Data +Increase or -Decrease keys to

change the sign of the percentage displayed. If it is (+),

change it to (-), or vice versa. Only change the sign of the

number, you can decrease its value later if you need to.

8. If the elevator servo plugged into CH2 goes the correct

direction with elevator stick, go to the next step. Otherwise,

press the Cursor Right key to get to the AIL->CH2 setting

menu, then press the Data +Increase or -Decrease keys to

change the sign of the percentage displayed. If it is (+),

change it to (-), or vice versa. Only change the sign of the

number, you can decrease its value later if you need to.

9. If the elevator servo plugged into CH5 goes the correct

direction with elevator stick, go to the next step. Otherwise,

press the Cursor Right key to get to the ELEV->CH5 setting

menu, then press the Data +Increase or -Decrease keys to

change the sign of the percentage displayed. If it is (+),

change it to (-), or vice versa.

Airplane Model Function Descriptions - Page 40

Airplane Model Function Descriptions - Page 41

10. Once you have all the servos moving the correct directions,

you can go back and adjust each of the travels

independently, so that both elevator servos move up the

SAME amount when elevator control is given, and move

opposite the same amount for aileron command. You will

need to decrease the percentage shown for the one moving

further, or increase the percentage for the one moving less.

FAIL - Failsafe Function

Setting Up the FAILSAFE Function

QPCM Operation

Activating the Hitec QPCM Failsafe

The failsafe feature of Hitec's QPCM receiver, model number

HPD-07RH is a safety feature designed to allow the user to

program a "set" position for a flight control surface to be at,

in the event of a loss of signal from the transmitter.

Your Optic system contains special programming to allow you

to fly a model using Hitec's special QPCM software. In this

menu, which only appears when QPCM is selected in the

power-on menus, you can choose where your servos are

commanded to move if the receiver loses the signal from the

transmitter due to interference.

Note: The OPTIC 6 QPCM is NOT compatible with Hitec's older

HPD-07RB PCM receivers and must be used with Hitec's

HPD-07RH QPCM receiver.

Note: Failsafe does not have to be activated to use the QPCM signal.

You do have the choice of using or not using the failsafe function.

1. To access this screen, turn on the transmitter.

2. Turn on the receiver power.

3. Press both Edit keys at the same time enter the menu loop.

4. Use the Edit keys to scroll down or up through the menu

until you come to the Failsafe screen.

5. The default position has the failsafe feature inhibited.

6. Arm the failsafe feature by pressing the "Clear" key, the

screen should now read, FAIL On.

7. To set the desired servo position when failsafe lockout

occurs, move the control sticks to the position you want the

control surfaces to be in if a failsafe condition should occur,

hold the sticks in this position and press both Data keys at

the same time. You should hear a double "beep"

8. Cycle the transmitter on, then off, then back on.

9. Test the effect by turning off your transmitter and watching

the servo failsafe position activate.

10. To change the failsafe hold positions, repeat step

7, 8 and 9.

Aircraft Flight Trimming Chart

The following chart may be used to systematically set up and trim a model for straight flight and aerobatic maneuvers.

Please note that for best results, trimming should be done in near-calm conditions. Before you decide to make a change,

be sure to try the test several times before making adjustments. If any changes are made, go back through the

previous steps and verify that they are not also affected. If they are, make further adjustments as necessary.

1. Control

neutrals

Fly the model straight and

level

Use the transmitter trims for hands-off

straight & level flight.

Change electronic subtrims

or adjust clevises to center

transmitter trims.

To test for...

Test Procedure

Observations

Adjustments

Master control

Slave Ch.

Flashing

Flashing

Flashing

Flashing

Flashing