HITEC Optic 6 User Manual

Page 10

Simple Transmitter Setup - Aerobatic Airplane (ACGL Menu)

Simple Transmitter Setup - Aerobatic Airplane (ACGL Menu)

If the rudder moves the wrong direction, move over to Channel

4 by pressing the Cursor Right key. Now the '4' should be

flashing in the display. Activate the opposite direction for the

rudder servo by pressing the Active/Inhibit (Clear) key. Move

the left-hand stick left-and-right again and verify the rudder

moves the right direction.

If your model has retracts, set the correct response direction

when commanded by the Gear (SW-2) switch, using the same

procedure.

If you're using a second aileron servo, you'll now set the left

aileron servo direction (otherwise skip this and the next step).

This is channel 6, and the '6' should be flashing for this

command. When you move the right-hand stick to the right, the

aileron on the left wing should move downwards. Check that

the left aileron moves the correct way! If it does not, activate

the opposite direction for the left aileron servo using the above

procedures. Move the right-hand stick again and verify the left

aileron moves the proper directions.

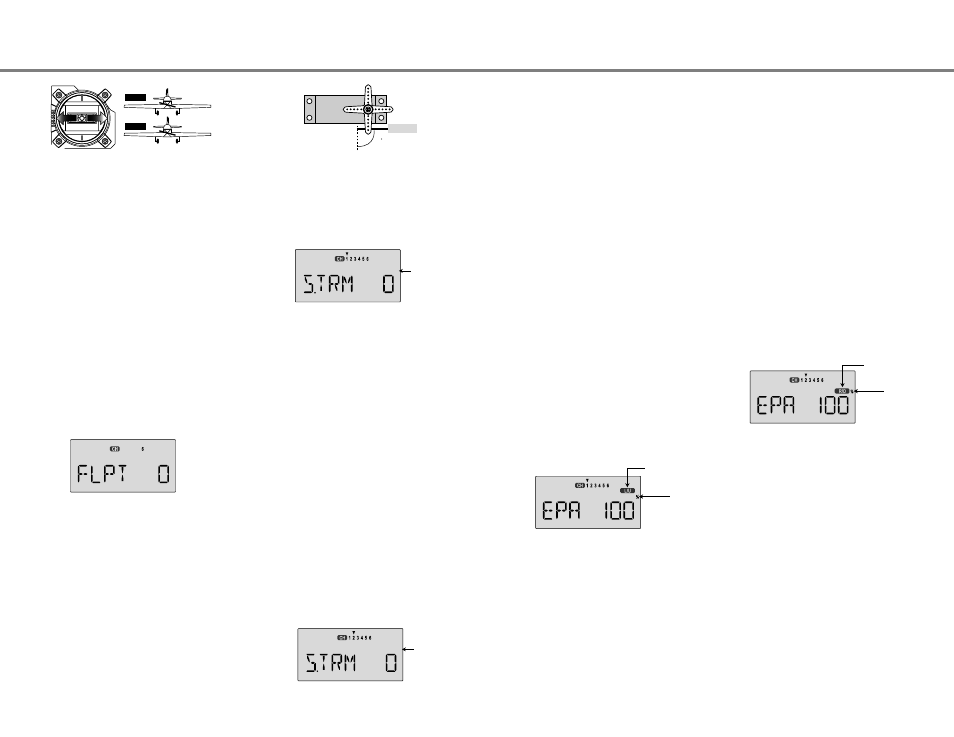

Press the Up or Down arrow keys to the Flap Travel function

(FLPT), and input a percentage of zero (0) using the Data -

Decrease key. This temporarily disables the flap lever (Right

Lever) so that you can set aileron neutrals without regard to

the flap lever position. Later we'll turn it back on.

23. Before we set the servo neutrals, we need to be sure that

all the trims are centered. Press both Edit keys to get to the

main menu, where voltage and time are displayed. Press

the Up arrow until the word TRIM appears. By moving each

of the four trim levers around, you can see their positions,

and move them back to zero for the next step.

24. Once you have centered all the trims, unscrew the screws

holding the servo arms onto the elevator, aileron, and

rudder (we'll set the throttle travel later). You will want to

place the servo arms on the output shaft so they are near

neutral - that is, about 90° to the servo case sides or, if

the servo is mounted sideways, 90° to the pushrod

(sideways mounting is not recommended). This way you

won't run out of subtrim authority. Remove all the arms

that are in the way or interfere with your pushrods.

Adjust the clevises on each servo pushrod to get the position of

each control to be as close as you can to neutral (lined up with

the adjacent portion of wing or tail).

Setting Subtrims. Now we'll adjust all the subtrims to

electronically set the desired neutral locations. To do so, go

back to the programming menu by pressing both Edit keys,

then press the Up or Down arrow key repeatedly until STRM

appears.

25. Set the right aileron subtrim first. If the little arrow is not

pointing at channel 1, press the one of the Cursor Left or

Right buttons until it is (see figure). Then, adjust the

subtrim amount by adding or subtracting with the Data

+Increase or -Decrease keys. When you reach a place

where the right aileron matches up with the fixed portion of

the wing, you are done. If you can't get both to match up,

then set the subtrim back to zero and mechanically adjust

the clevis to get as close as you can, then readjust the

subtrim if necessary.

26. Note 1: you should NOT use subtrims instead of

mechanically adjusting the pushrods to be close. This is

because you can reduce the travel of the radio, especially

if you have to set the subtrim at or above 50%. As we

stated before, get the pushrods close mechanically first,

then use the subtrim adjustment to get it just right.

27. Note 2: if you mess up the number you've entered or find

the percentage the wrong direction, you can get back to

zero quickly by pressing the Active/Inhibit (Clear) button.

28. Repeat the subtrim adjustment with the elevator servo (CH2).

First set the pushrod length mechanically to get as close to

neutral as possible, then set the subtrim to get the elevator

lined up to be parallel with the stabilizer portion. For

full-flying surfaces, use an incidence meter or another

method to get the incidence angle recommended by the kit

manufacturer or model designer.

29. For the throttle, we recommend not setting a subtrim at this

time. You will use the trim tab on the transmitter for setting

your idle RPM. To shut off the motor you will use the

Engine Cut function. In this way, you don't lose your

carefully-set idle position.

30. Most people set up their engines to idle with the throttle

trim near center, so that there is room for changes due to

humidity and other factors.

31. The Optic provides a special throttle trim function which

allows the throttle trim lever to work at low throttle levels,

but disables it at high throttle.

32. Repeat the subtrim adjustment with the rudder (CH4),

gear (CH5), and 2nd aileron channel (CH6). As before,

first set them mechanically, then adjust the electronic

settings. Be sure you have selected the appropriate

channel number each time.

33. Servo EPA (End Point Adjustment). Now we'll go through

and set the servo travels for each channel. This is both

helpful and important, because you can set the throw of

each servo, in each direction, so that there is no binding.

Eliminating binding is important because it causes very

high current drain, and can lead to a battery dying

prematurely. Another use for the EPA function is to adjust

the model's total throws to match the recommended control

motions specified on the plans or instructions by the

model's designer.

34. To set travels, get to the EPA menu by pressing one of the

Up Down Edit buttons repeatedly until EPA appears. In

sequence, we'll set right aileron right travel, right aileron left

travel, up and down elevator travels, right and left rudder

travels, open and closed throttle positions, and left aileron

travels.

35. When you reach the EPA menu, you'll see the screen as

shown. The channel indicator is above numeral 1 for right

aileron, the percent symbol will be flashing, and you'll

notice that you can change the L/U indicator to R/D (or vice

versa) by moving the aileron (right) stick. You are about to

see that this is how you set the travel directions

independently for each stick motion.

36. To set the RIGHT aileron motion, move the aileron stick all

the way to the right and hold it. The letters "R/D" should

appear next to the flashing percent sign, meaning you are

setting either Right or Down travel (with ailerons it's right or

left only, but the display is set up to use the same indicators

for elevator and throttle, thus the dual meanings for the

letters). Now if your servo is stalled or binding, you'll hear

a buzzing sound. Hit the minus -Decrease Data key until

the buzzing stops. If the servo is not buzzing, leave the

setting at 100%. If you can, choose a location for the

pushrod on the servo arm so that the throw is adjusted in

the 90-100% range.

37. To set the right aileron's LEFT motion, move the aileron

stick all the way to the left and hold it. The letters "L/U"

should appear next to the flashing percent sign (as shown

in the figure above). Again listen and hit the -Decrease

Data key until the buzzing stops. If the servo is not buzzing,

leave the setting at 100%. (Remember, you're only setting

the right aileron travel. You set the other aileron's travel in

channel 6's EPA.)

38. To set the UP elevator motion, press on the Right Cursor

key until the indicator moves over channel 2. Now move

the right stick all the way to the transmitter bottom and hold

it. The letters "L/U" should appear next to the flashing

percent sign. Again listen for a buzzing sound to indicate

the servo is stalling, and hit the -Decrease Data key until

the buzzing stops. If the servo is not buzzing, leave the

setting at 100%.

39. Repeat the previous step for DOWN elevator by moving

the stick all the way to the top of the transmitter, full "down"

elevator. Check for binding and adjust the percentage as

before.

40. To set the throttle position at IDLE, first return to the regular

display and set the throttle trim to +25%. Then go back to

the EPA menu and press the Right Cursor key until the

arrow moves over channel number 3. Now move the

throttle stick all the way to the transmitter bottom and hold it.

The letters "L/U" should appear next to the flashing percent

sign. Listen for a buzzing sound to indicate servo stalling,

and hit the -Decrease Data key until the buzzing stops.

Change the setting to nearly - but not completely - close

the throttle (engine idle). Later you may increase or

decrease this number so you can't accidentally shut off the

engine using the trim tab.

Front View

LEFT

RIGHT

RIGHT

LEFT

Servo

Pushrod

90

Changes from L/U to

R/D with AIL stick motion

Flashing

Changes from L/U to

R/D with ELE stick motion

Flashing

Simple Transmitter Setup - Aerobatic Airplane (ACGL Menu) - Page 19

Simple Transmitter Setup - Aerobatic Airplane (ACGL Menu) - Page 18

%

Flashing

%

Flashing