15 replacement of parts, 3 silencer assembly – Glow-worm Ultrapower sxi Range User Manual

Page 56

56

15 Replacement of Parts

15.1 General

Replacement of parts must be carried out by a

competent

person approved at the time by the Health and Safety

Executive.

IMPORTANT:

The following replacement of parts described

in sections 15.7 to 15.12 and section 15.14 will require the

removal of the burner module assembly and the replacement

of seal and self locking nuts.

Replacement parts that have associated components that

need replacing on removal, i.e. ‘O’ ring, seals, gasket, etc.,

will be supplied and should be fitted.

Before replacing any parts the boiler and immersion heater

should be isolated from the mains electric supply and the gas

should be turned off at the gas service isolation valve on the

boiler, see diagram 12.1.

Unless stated otherwise parts are replaced in the reverse

order to removal.

After replacing any parts always test for gas soundness and if

necessary carry out functional test of the controls.

For replacement of parts the front casing panels will need to

be removed.

The tank module front panel will need to be removed first to

gain access to the boiler module front panel securing screws.

Remove the two screws on the underside of the panel and lift

off, see diagram 13.2.

For ease of servicing, the control box and domestic expansion

vessel can be moved into their service positions, this will

improve access to hydraulic components, see diagrams 13.4

to 13.6.

Draining of Boiler Heating Circuit

To drain the boiler heating circuit, isolate the flow and return

valves, see diagram 12.1.

Open the top tap on the filling loop to drain the boiler out

through the filling loop hose.

After servicing or replacing parts open the heating flow and

return isolating valves and refill, vent and pressurise the

heating circuit, refer to section 12.3.

Close the drain valve and disconnect the hose.

Check for leaks.

Draining of Boiler Domestic Water Circuit

Drain the domestic water circuit by closing the cold-water

isolation valve, see diagram 12.1.

Open one or more hot water taps to drain the hot water circuit.

After servicing or replacing parts open the cold-water isolation

valve and slowly open a hot water tap to remove air. Close the

hot water tap and check for any leaks.

15.2 Domestic Expansion Vessel

For access, refer to section 15.1.

Isolate the DHW inlet valve, see diagram 12.1 and drain

through a domestic tap.

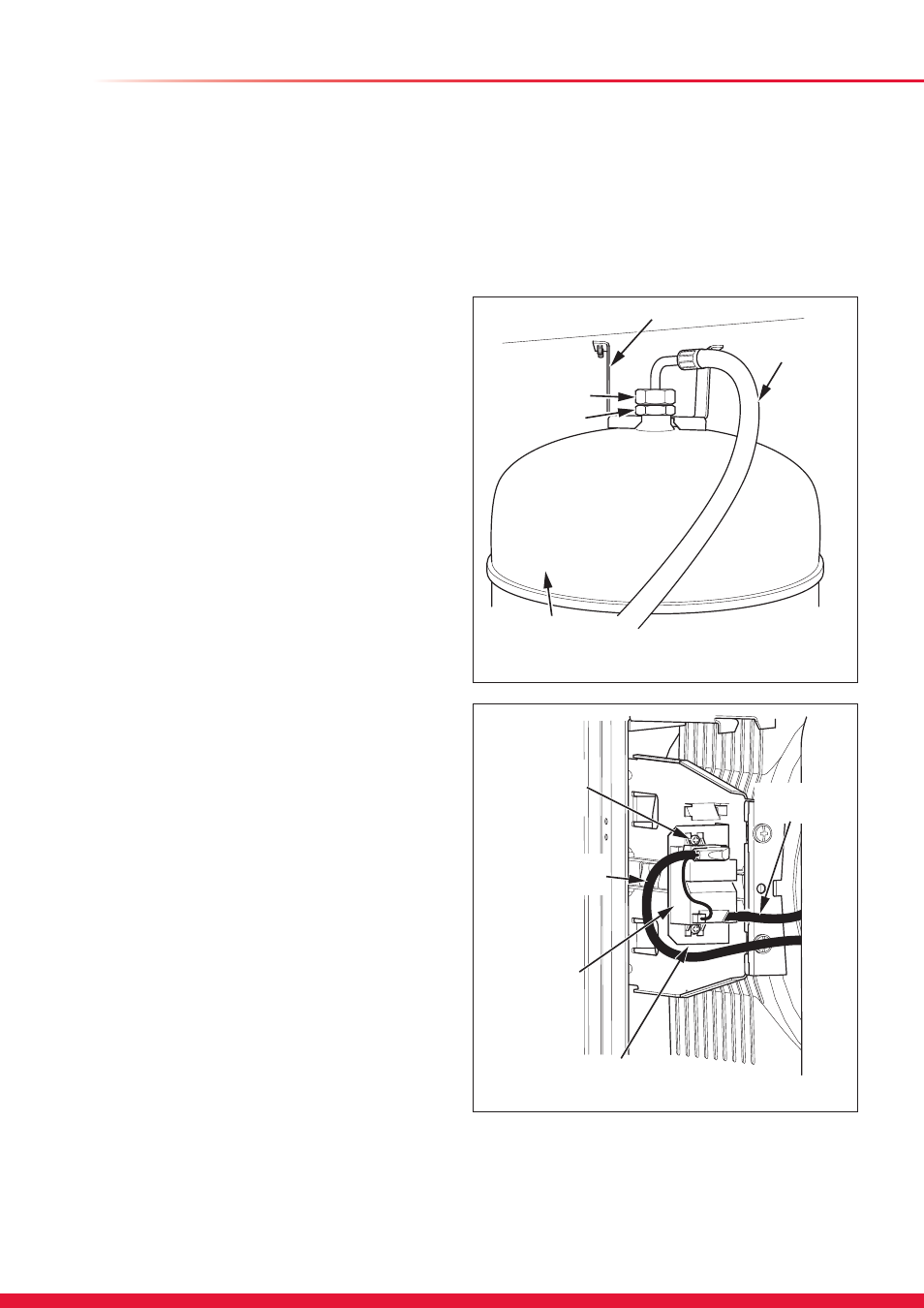

Loosen the locknut at the top of the vessel, see diagram 15.1.

To remove the expansion vessel slide forward out of its

hanging bracket.

Remove the flexible hose from the expansion vessel by

undoing the union nut and lock nut, see diagram 15.1.

Fit a new rubber seal in union nut on flexible hose.

Fit the replacement unit.

Refill, vent and pressurise the boiler.

Check for leaks.

Diagram 15.2

13341

IGNITER

UNIT

BRACKET

SECURING

SCREW

(2 OFF)

IGNITION

LEAD

ELECTRICAL

CONNECTION

13330

DOMESTIC

EXPANSION VESSEL

FLEXIBLE

HOSE

BRACKET

UNION NUT

LOCK NUT

Diagram 15.1

15.3 Silencer assembly

For access, refer to section 15.1.

To aid access to the silencer and securing screw, slacken

the locknut at the top of the domestic expansion vessel, see

diagram 15.1 and slide the vessel forward out of its bracket

and put in its service position, see diagram 13.6.

To remove, undo the securing screw and pull the silencer from

the fan, this is a push fit so no tools or fixings are required for

its removal or fitting, see diagram 13.7.