13 servicing, 1 servicing – Glow-worm Ultrapower sxi Range User Manual

Page 45

45

13 Servicing

If the combustion reading is not within the acceptable values

AND the integrity of the complete flue system and combustion

circuit seals have been verified and the inlet gas pressure

(and gas rate) have been verified, then, it will necessary to

adjust the combustion rate of the appliance.

NOTE: Adjustment is made by turning the gas valve throttle

an ⅛ of a turn, waiting 1 minute to allow the appliance to

stabilise before checking or making further adjustments.

● Remove the sticker covering the “throttle” adjustment screw,

if fitted.

● Rotate the “throttle” (anti-clockwise to increase), to the

required CO2, refer to diagram 13.13 and the “SETTING”

column in the table.

● Exit the forced rate function, press the “mode” and “+”

buttons simultaneously, this will reset the boiler to the default

display. Now proceed to check the minimum rate adjustment.

GAS RATE CHECK

Check the gas rates as described in the commissioning

section.

COMPLETION

If it is not possible to achieve the required results for either

the combustion or gas rates, it will be necessary to complete

a full service of the appliance and then repeat the combustion

check procedure. If after servicing and adjustment of the

appliance the combustion values are still unacceptable

and after further remedial work has been carried out, the

appliance must be disconnected until the CO/CO2 ratio

is acceptable. Advice can be sought from the Glow-worm

Technical Helpline.

13.1 Servicing

NOTE: If the Combustion CO2, CO/CO2 ratio and Gas rate

checks did not require adjustment then it will not be necessary

to complete a full service.

All routine servicing requirements can be achieved by the

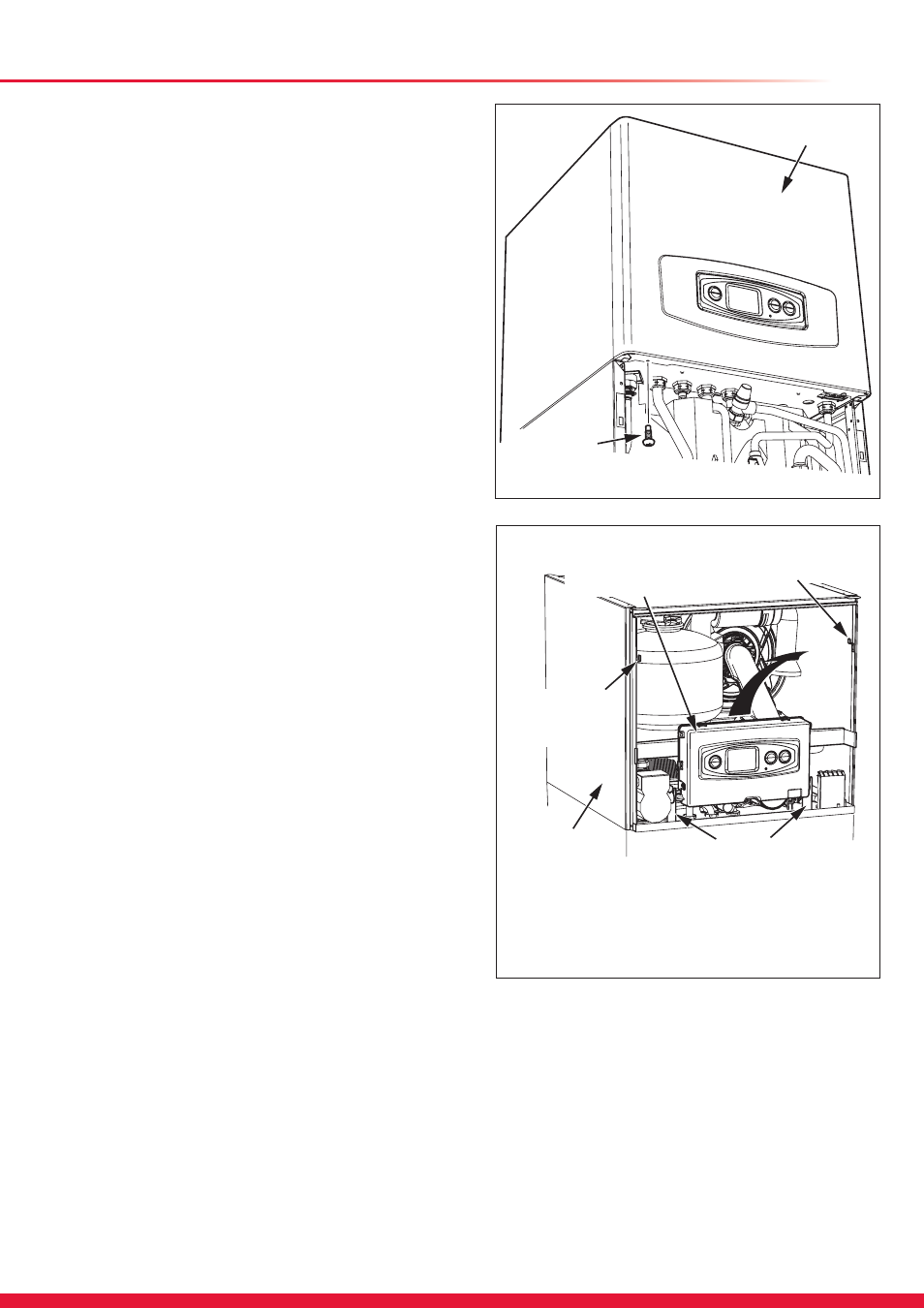

removal of the front panels, see diagram 13.2.

Position the control box and domestic expansion vessel into

their service positions, see diagrams 13.3 to 13.6.

Before commencing with a service or replacement of parts.

The boiler should be isolated from the electrical and gas

supplies see diagram 12.1 for the position of the gas service

isolation valve.

BOILER MODULE

FRONT PANEL

SECURING

SCREW (2 OFF)

13440

Diagram 13.2

Diagram 13.3

13417

CONTROL BOX

MOUNTING BRACKETS

CONTROL BOX

SERVICE

BRACKET

*

To move the control box into its service position

carefully pull the control box forwards and

upwards to release from its mounting brackets.

BOILER

MODULE

*

CONTROL BOX

CONTROL BOX

SERVICE BRACKET