Glow-worm Ultrapower sxi Range User Manual

Page 35

35

10 Twin Flue - Length, Preparation and Installation

10.12 Twin flue

The twin flue system is available as an option when the top

outlet horizontal concentric rear or vertical flue system is not

appropriate, see diagram 10.26.

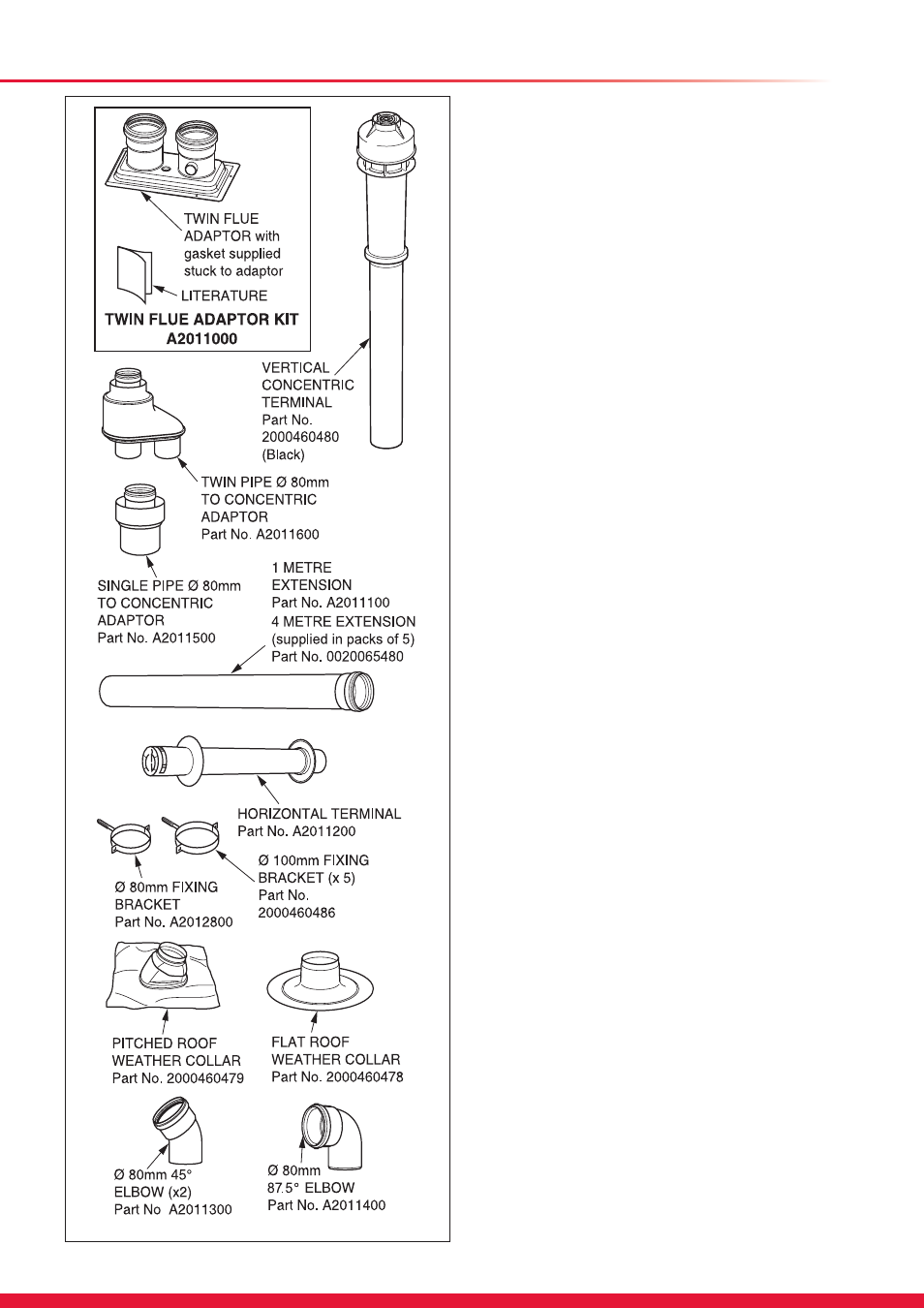

The system is made up of accessories. The accessories

include terminal assembly, bends 45º and 90º, flue extensions,

fixing bracket and appropriate weather collar, see diagram

10.27.

The system can provide an independent horizontal air inlet

and flue outlet, horizontal air inlet and vertical flue outlet or

vertical air inlet and flue outlet via a concentric terminal.

NOTE: The air and flue outlets do not have to be equal

lengths. 2x45° bends can replace 1x90° bend if necessary.

The maximum permitted combined straight pipe length is 40

metres plus terminal assemblies, for each 90°

or 45°

x 2 bends

fitted, the maximum length must be reduced by 1 metre.

NOTE: When using 90° bends any horizontal run should be

inclined by a minimum of 44mm/metre (2.5°) towards the

boiler to facilitate condense removal.

Alternatively use 45° bends to avoid horizontal runs in the flue

pipe.

Terminal Position

The clearances for a flue outlet are given in the "Flue Location

and Ventilation" section.

In addition the horizontal air inlet must not be closer than 300

mm from a flue outlet on the same wall or 1200mm from an

opposing flue outlet.

Installation Details

The parts available for a twin flue system installation are

shown in diagram 10.27.

Boiler Connection

IMPORTANT: The flue seals are sensitive to mineral oil based

lubricants.

Do not grease the seals. If the seals do need to

be lubricated

use only water.

Push the twin flue adaptor onto the outlet of the boiler with the

air inlet to the left hand side. Secure the adaptor to the top

panel with the screws provided. Care should be taken when

inserting the screw through the hole in adaptor top.

Air and Flue Pipe Installation

The air and flue pipes can now be built up from the boiler.

The flue must be designed with a continuous fall towards the

boiler. If using the horizontal flue pipe or 90° bends the pipe

must be inclined at 44mm/metre (2.5°)

minimum, see diagram

9.25.

Alternatively if space allows, use 45° bends in place of 90º

bends.

To avoid rain ingress to the air Inlet terminal, it is good practice

to aim the inlet downwards by approx 2° as rain can damage

the boiler. The Flue outlet pipe must always run at 44mm/

metre (2.5°) back to the boiler.

IMPORTANT:

Long lengths of flues must be secured to the wall or ceiling it

runs against. Use at least one fixing bracket on each flue joint

used or on straight flue runs every joint and for every metre

flue run.

Provision must be made in concealed boxing or ductwork that

the flue joints can be inspected during annual servicing.

The flue seals are sensitive to mineral oil based lubricants.

Do

not grease the seals. If the seals do need to be lubricated

use only water.

Do not use the flue pipe to attach other pipes or equipment.

If visible, advise the householder not to hang or clip items to

flue pipes.

Diagram 10.27

14869