8 gas, water & boiler connection – Glow-worm Ultrapower sxi Range User Manual

Page 20

20

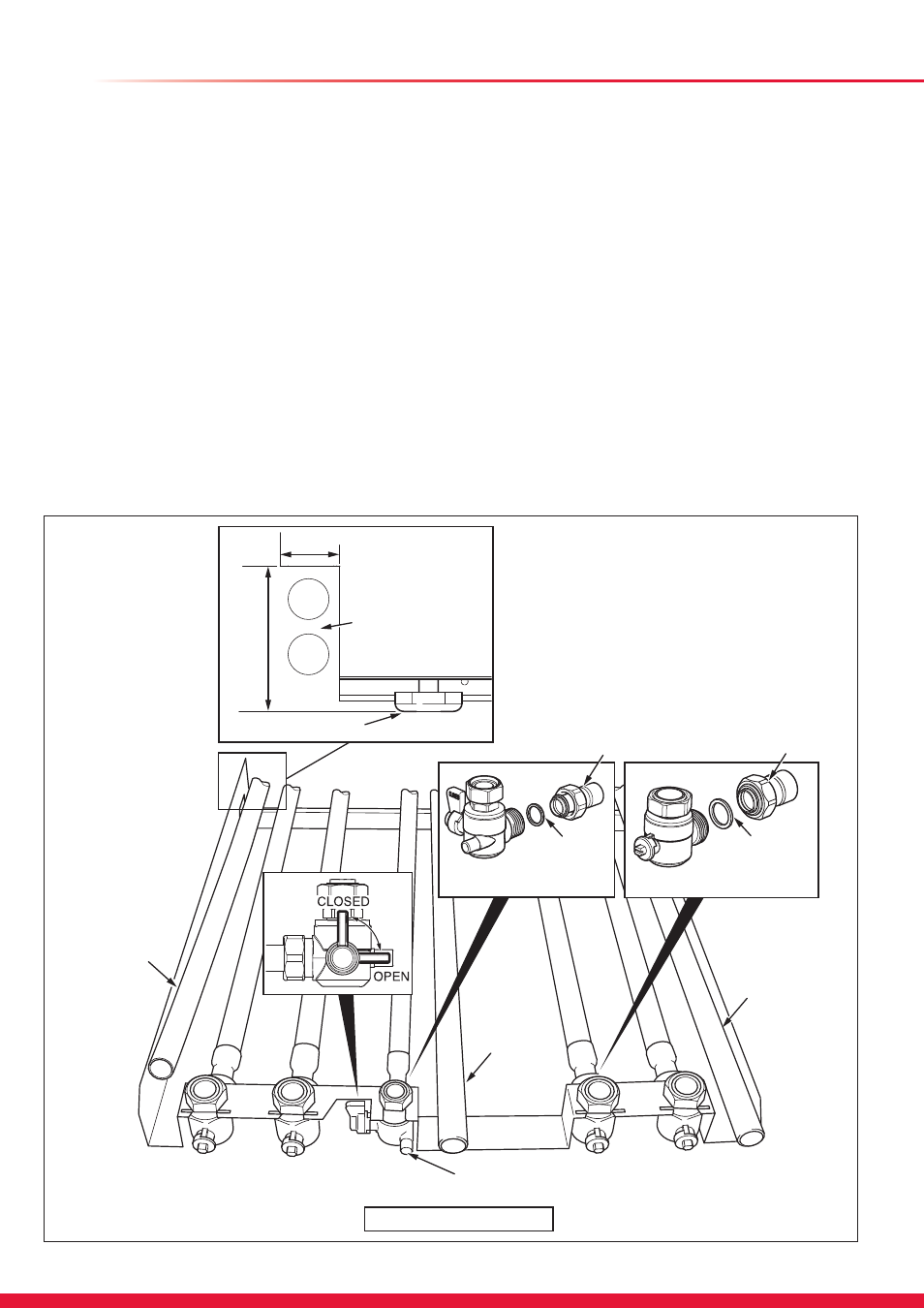

CENTRAL

HEATING

RETURN

CENTRAL

HEATING

FLOW

VALVES SHOWN CLOSED

DHW

OUTLET

GAS

DHW

INLET

CONDENSATE

DRAIN

PIPE WORK

ROUTING

(IF REQUIRED)

ADJUSTABLE FEET

31

68/78

VIEW SHOWING

SIDE OUTLET PIPE WORK

ROUTING AT BACK OF

BOILER (IF REQUIRED)

CH SAFETY

RELIEF

VALVE

DISCHARGE

DHW SAFETY

RELIEF

VALVE

DISCHARGE

15mm

COPPER TAIL

22mm

COPPER TAIL

SEALING

WASHER

ISOLATION VALVE (typical)

GAS ISOLATION VALVE

SEALING

WASHER

GAS INLET

PRESSURE

TEST POINT

8 Gas, Water & Boiler Connection

8.1 Systems Connection

The water and gas isolation valve connections are on the jig.

The condense drain and safety discharges connections are

not on the jig but their pipe runs are shown on the template.

Assemble the copper tails and washers to the jig, secure,

then plumb the system as shown in diagram 8.1. taking into

account the need to plumb the condense and safety valves

also.

NOTE: Do not subject isolation valves to heat.

Slacken the test point screw, see diagram 8.1, connect a

manometer.

The whole of the gas installation, including the meter, should

be inspected, tested for tightness and purged in accordance

with the current issue of BS6891 and in IE the current edition

of I.S.813 “Domestic Gas Installations”.

Remove the manometer and secure the test point screw.

On completion of system connections and as an aid to

installation, slacken the jig securing screws, this will allow

a greater tolerance of site conditions when connecting the

isolation valves to the boiler.

Diagram 8.1

13402

IMPORTANT:

With regards to the Health and Safety

Manual Handling requirements, two persons shall be required

to lift the appliance. It should be noted that the appliance is

made up of two modules each module requiring two persons

to lift.

8.2 Tank Module Connection

IMPORTANT:

The electrical cables to the boiler and the

immersion heater need to be routed before the installation of

the tank module.

Remove the tank module top polystyrene packing, then the

carton sleeve.

Pull the tank module front panel forward off the retaining clips.

Slide the tank module into position over the jig and align with

the isolation valves.

NOTE:

If there is restricted clearance where the boiler is

to be located, the tank and boiler modules can be assembled

before sliding into position over the jig.

Position the plastic sealing washers as shown in diagram 8.3

and connect the isolation valves. The pipe retaining bracket

can be slackened to ease connection.