Troubleshooting – Dillon Precision SL 900 User Manual

Page 46

Troubleshooting Section #1, Primer System

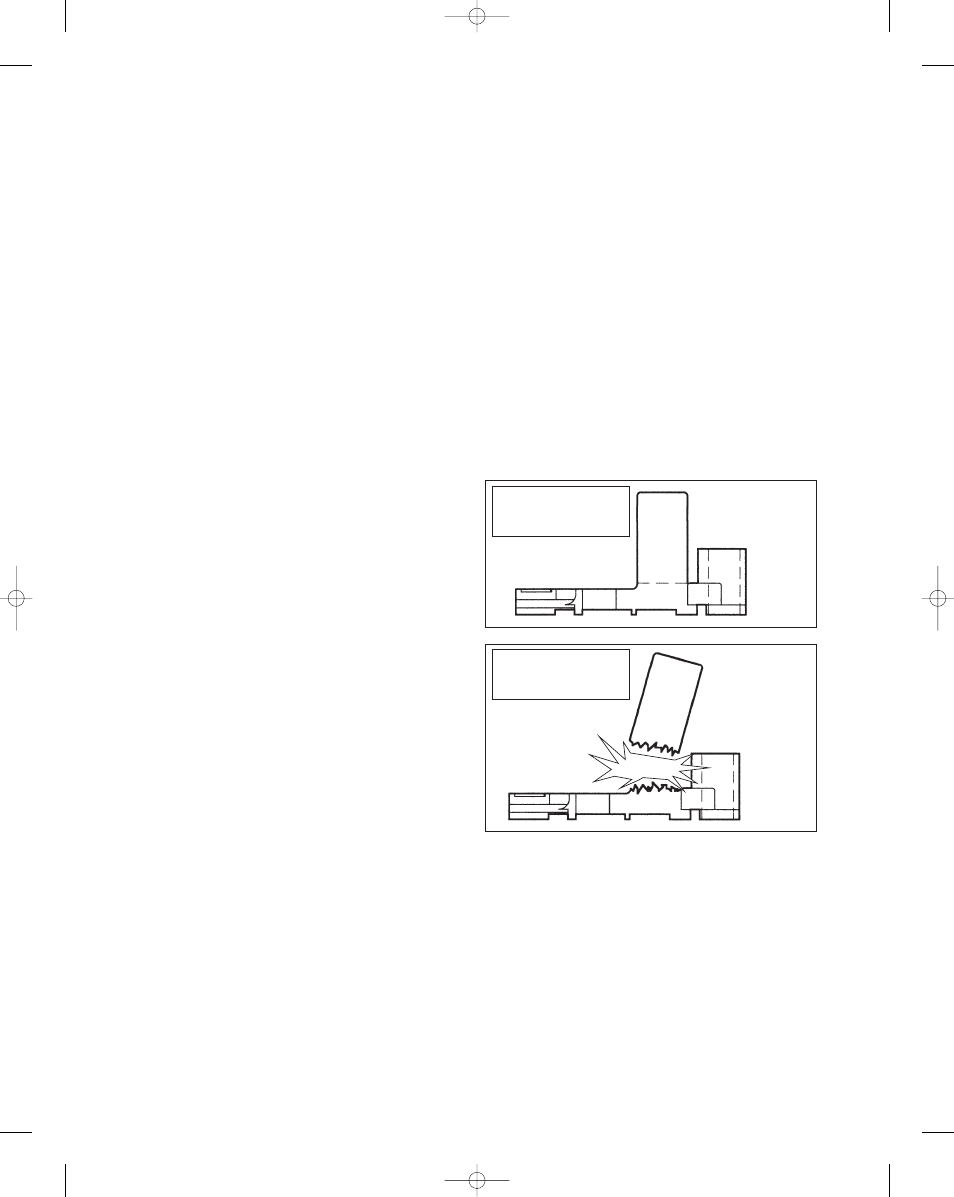

1. I broke my primer transfer arm (#16691). This

happens when a new primer is only partially seated

into the shotshell. A spare is included with the

machine, but it’s important that you make complete,

full strokes of the operating handle when using the

SL 900. See Illustrations 1 & 2

2. A primer is laying sideways inside the clear

cover of the primer tray. How do I remove it?

Shotshell Primers are steel – get a small magnet,

screw-driver or pointer and use it to get that primer

out. Dillon also provides a magnetic pick-up wand

(#22292) as an accessory for the SL900.

Another method available is to simply unscrew the

black knobs that secure the cover, slide the clear

cover off, and remove all the primers. Reassemble the

parts, then refill the primer tray with primers.

3. From time to time I notice that a new primer

lands on the platform rather than into the hole in the

primer transfer arm. Why? Two things may be

occurring here: First, the speed in which you operate

the handle affects the feeding of new primers. As the

new primer is dispensed from the primer tray, it takes

a fraction of a second to fall through the tube and into

the hole in the primer transfer arm. When you reach

the bottom of the handle’s stroke, pause for a second,

then move the handle again. Always pace yourself

when operating your machine.

Second, you always get a new primer with every

complete stroke of the machine’s handle. If there isn’t

a shotshell in station two to receive the primer, that

primer will be left on the platform.

4. A dirty primer tray can be annoying. If you

reload in a dusty environment (for instance, a barn or

garage) or the shotshells you have are dirty, over time

dust will collect on the primer tray. We've made the

primer tray stainless steel so you can clean it with

windex or alcohol. Just remove the clear cover and

wipe it clean. Our machine cover was designed to

help keep your loader clean when you're not using it.

Ask for part #13329.

5. Where does the grease go again? See page 37

in the manual, also make sure your hands are grease-

free when handling new primers; they don't feed well

in any machine when they’re greasy.

6. How do I stop the primers from feeding? A

rectangular insert has been included with the

machine. Place your thumb on the primer drop tube

and raise the primer system by pushing it up. Insert

the stop block BETWEEN the primer feed body and

the tray mounting bracket. Remove the stop block

when you're ready to begin reloading again.

7. When I operate the machine, it doesn’t always

drop a primer. An adjustment screw (#17639, see the

schematic on page 13) is located in the platform. This

screw increases or reduces the stroke of the black

primer slide located on the primer tray via the primer

drop tube. If the primer moves over the hole but it

does not drop thru, turn the adjustment screw

counterclockwise to raise the primer drop tube and

the black primer slide will stroke more and then the

primer will drop thru the hole.

The adjustment screw (#17639) may periodically

go out of adjustment. Remove the screw and clean

the threads and the hole in the platform with alcohol.

Apply some blue Loctite to the threads and reinstall.

8. Why do I get high primers when using

Winchester primers and Remington hulls, but not

when using Remington hulls and primers? The new

silver colored Winchester primers appear to be .002

diameter larger than the previous copper colored

primers at the point just above the flange. We suggest

using a bit more forward push on the operating

handle when seating the primer or switching to

Remington primers for Remington hulls.

Illustrations 1 & 2

Inside your parts bag you will find an extra primer

transfer arm, #16691, see illustration 1. While every

effort has been made to manufacture a sound

machine for you,

it’s important that you make

complete, full strokes of the operating handle when

using the SL 900. Assure yourself that the primer is

fully seated into the shotshell. We’ve found that the

primer transfer arm WILL break if the primer is only

partially seated into the shotshell. Never force the

handle when a jam occurs, instead, slowly return the

handle to its rest position. When the shotshells appear

out of the bottom of the dies, remove the suspect

shotshell from the priming station. Once you have

46

SNAP!

Illustration 1

Primer Transfer Arm

Illustration 2

Primer Transfer Arm

Troubleshooting

SL 900, May 2007 5/21/07 11:51 AM Page 46