Dillon Precision SL 900 User Manual

Page 28

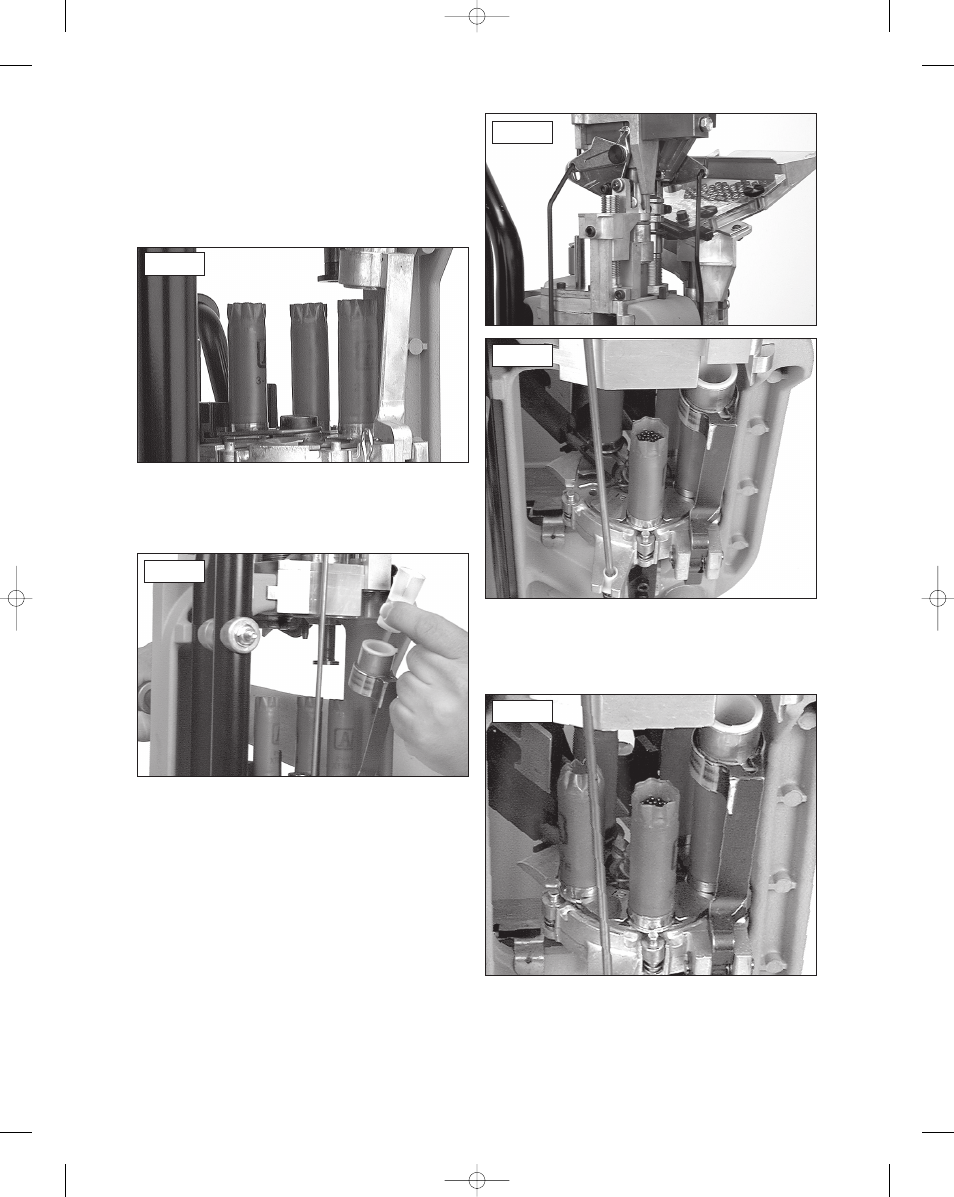

shellplate at station one. To ensure that you have fully

seated the primer into the hull, it is important to

stroke the operating handle to its full aft position.

With experience, you will acquire the “feel” of the

primer being seated fully. Fig. 48

6. Move the roller handle (#22183) down. The first

hull is getting a charge of powder at station two.

7. Return the roller handle (#22183) to its rest

position. The first hull advances to station three,

another fired hull is fed to the shellplate and the hull

at station two is ready to receive a new primer. Fig. 49

8. Push the roller handle (#22183) to its full aft

stop and hold as (using your left hand) you pick up a

plastic wad and place it into the wad guide (#16681).

This same aft stroke seated the new primer into the

hull at station two and the hull at station one is fully

seated into the shellplate. Release the roller handle

(#22183). Fig. 50

9. Move the roller handle (#22183) down. The first

hull is at station three, where a new plastic wad is

seated. It then receives a charge of shot. Again, the

hulls in station one and station two are being

processed as well.

Fig. 51

10. Raise the roller handle (#22183) to its full aft

stop. The first hull advances to station four and the

other hulls advance as well. Fig. 52 If you encounter

resistance, STOP! Do not force the handle. There may

be something blocking the primer transfer arm. See

the troubleshooting section for instructions on how to

proceed.

11. Push the roller handle (#22183) aft to seat the

primer into the hull at station two and place a new

plastic wad in the wad guide (#16681).

Special note: An important step in the loading

process – remember when pushing the roller handle

(#22183) aft to seat the new shotshell primer, you

must also place a new plastic wad into the wad guide

(#16681) at the same time. See Fig. 50

12. Move the roller handle (#22183) down. The

28

Fig. 52

Fig. 53

Fig. 49

Fig. 50

Fig. 51

SL 900, May 2007 5/21/07 11:51 AM Page 28