28 gauge conversion instructions – Dillon Precision SL 900 User Manual

Page 36

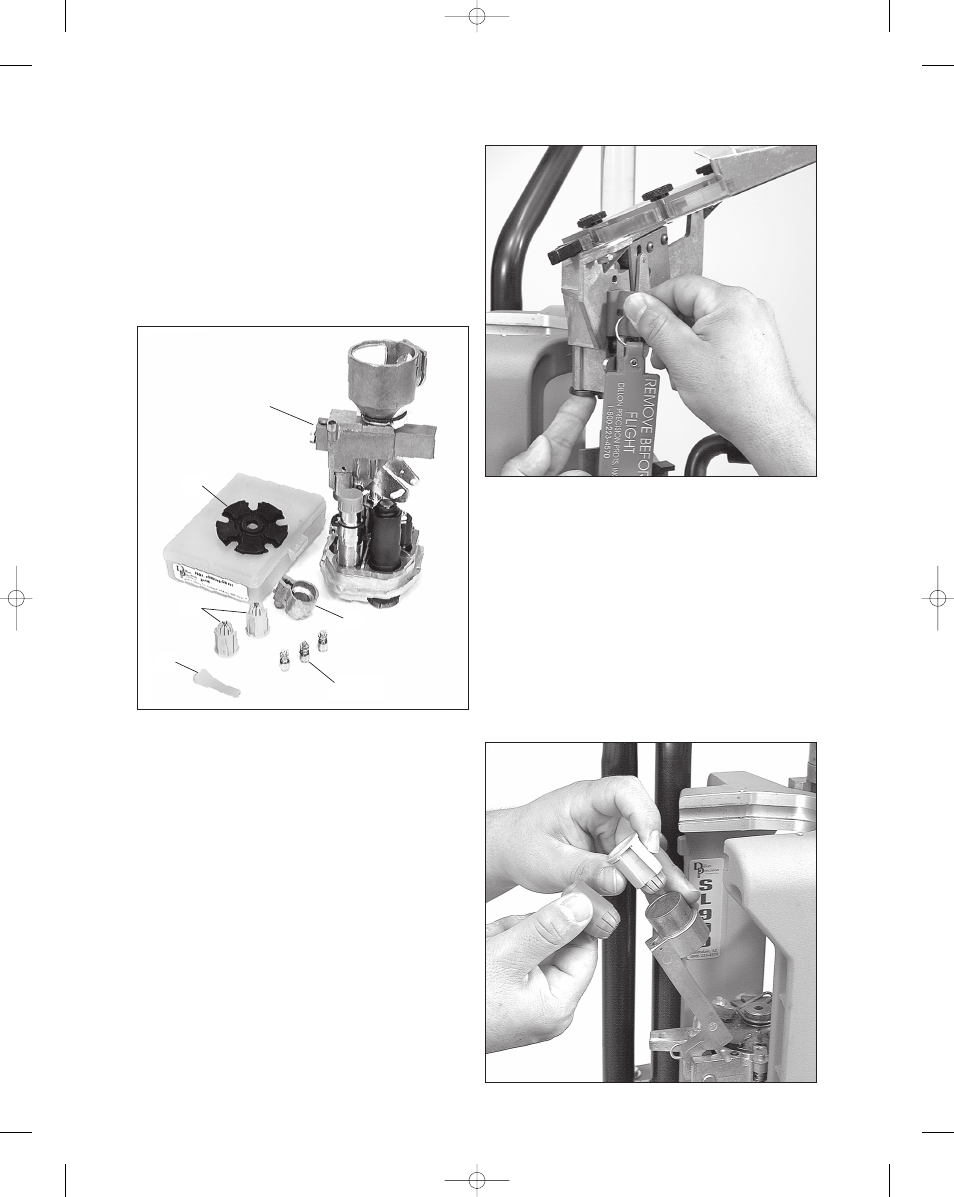

A 28 gauge conversion package (#22139),

includes the following items:

1.) A complete toolhead assembly with dies

installed; Station 1, collet sizer & depriming pin

assembly. Station 2, powder die with 28 gauge

powder funnel and retaining clip. Station 3, complete

shot dispenser assembly with 1/2 oz – 1.0 oz shot bar

and 28 gauge shot drop tube. Station 4, starter crimp

star/radius form insert. Station 5, new spring/over

floating taper crimp die.

2.) A 28 gauge conversion kit box containing: (a)

one 28 gauge shellplate (#10625), (b) three locator

buttons (#16753) with locator rings (#10602) and

springs (#17126), (c) one green station 2 locator

insert (#10624), (d) two green wad guides (1 spare,

#10620), (e) one 28 gauge casefeed sleeve assembly

(#22129). Fig. 1

Converting the Machine

The following is a step by step routine to use for

converting your machine to reload other gauges.

Refer to your SL 900 reloading manual as needed.

1. Drain the shot via the shot dispenser drain.

Hint, use an old coffee can, widemouth water jug or

shot bag to catch the shot.

2. Disconnect the return rods on both the shot and

powder dispensers.

3. Remove the shot fitting e-clip on the shot

dispenser and slide the fitting out of the dispenser

housing.

4. Remove the two black toolhead pins and

remove the toolhead from the machine.

5. Install the red flag block into the primer feed

assembly.

Fig. 2

Replacing the Shellplate and

Parts in the Platform

1. Remove the ejector wire (#16676).

2. Move the roller handle to the down position.

3. Use a 1/8" Allen wrench to loosen the 1/4-28

brass tip set screw 1/2 a turn. The brass tip set screw is

located on the left side of the machine, below the

platform, in the mainshaft.

4. While the machine is in this configuration, it is

a good time to exchange the red wad guide (12

gauge) with the green wad guide (28 gauge). Fig. 3

28 Gauge Conversion Instructions

Fig. 1

Fig. 3

Fig. 2

a

toolhead

assembly

b (3)

c

d

e

36

SL 900, May 2007 5/21/07 11:51 AM Page 36