Toolhead conversion and final assembly – Dillon Precision SL 900 User Manual

Page 39

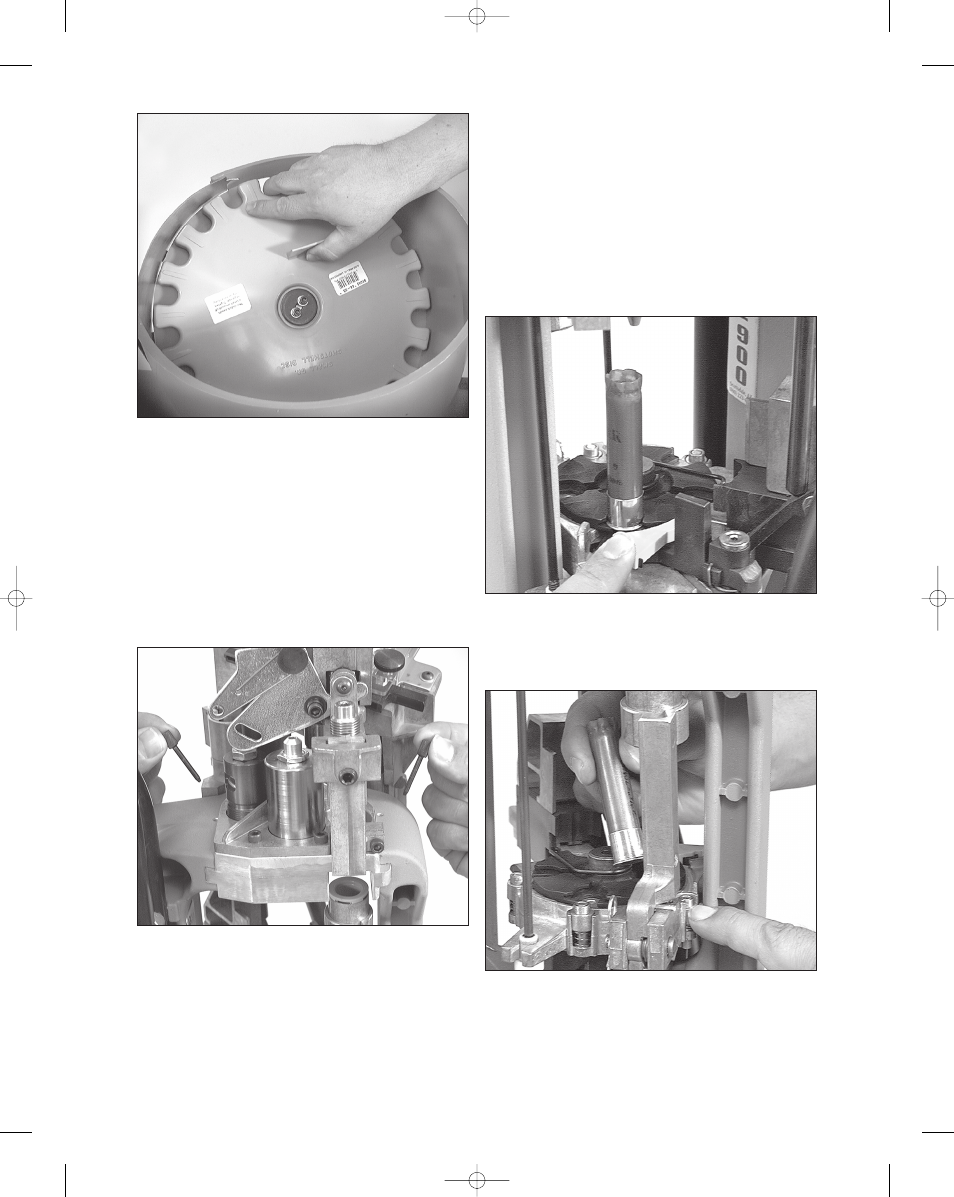

5. Install the small gauge disc into the casefeed

bowl. Rotate as needed until the motor driveshaft

enters the slot in the casefeed disc clutch.

Fig. 12

6. Reinstall the clear casefeed tube.

7. Test run the assembly by placing 3-5 empty,

once-fired hulls into the casefeed bowl and turn the

unit on. Once all the hulls have been fed into the

clear feed tube, turn the unit off.

8. Move the roller handle up and down until all

the hulls have cycled through the machine.

Toolhead Conversion

and Final Assembly

1. Slide the 28 gauge toolhead into the frame and

insert the two toolhead pins. Fig. 13

2. Install the powder measure; loosen the two

clamp screws and place the powder measure on the

powder die. Press the clamp forward into the groove

in the powder die and secure the two clamp screws

using a 5/32” Allen wrench.

3. Install both return rods onto the shot dispenser

and the powder measure.

4. Realign the shot hopper tube fitting with the

shot dispenser. Insert the fitting and the e-clip into the

dispenser top.

5. Cycle the roller handle two complete cycles to

insure everything is free to move.

6. Fill the shot dispenser with one cup of shot.

7. Remove the lid on the powder measure and fill

with your powder of choice.

8. Use a once-fired hull, place the hull in Station 2

where the powder measure is located. Fig. 14

9. Move the roller handle down and then back

up to its rest position. Remove the hull from the

shellplate by pressing down on the locator button.

Fig. 15 Pour the powder back into the clear

powder hopper.

10. Repeat these two steps a minimum of four

times to make sure you are receiving a uniform

powder charge.

11. Weigh the fifth powder charge.

12. Adjust as needed.

Fig. 14

Fig. 13

Fig. 12

Fig. 15

39

SL 900, May 2007 5/21/07 11:51 AM Page 39