Dillon Precision SL 900 User Manual

Page 31

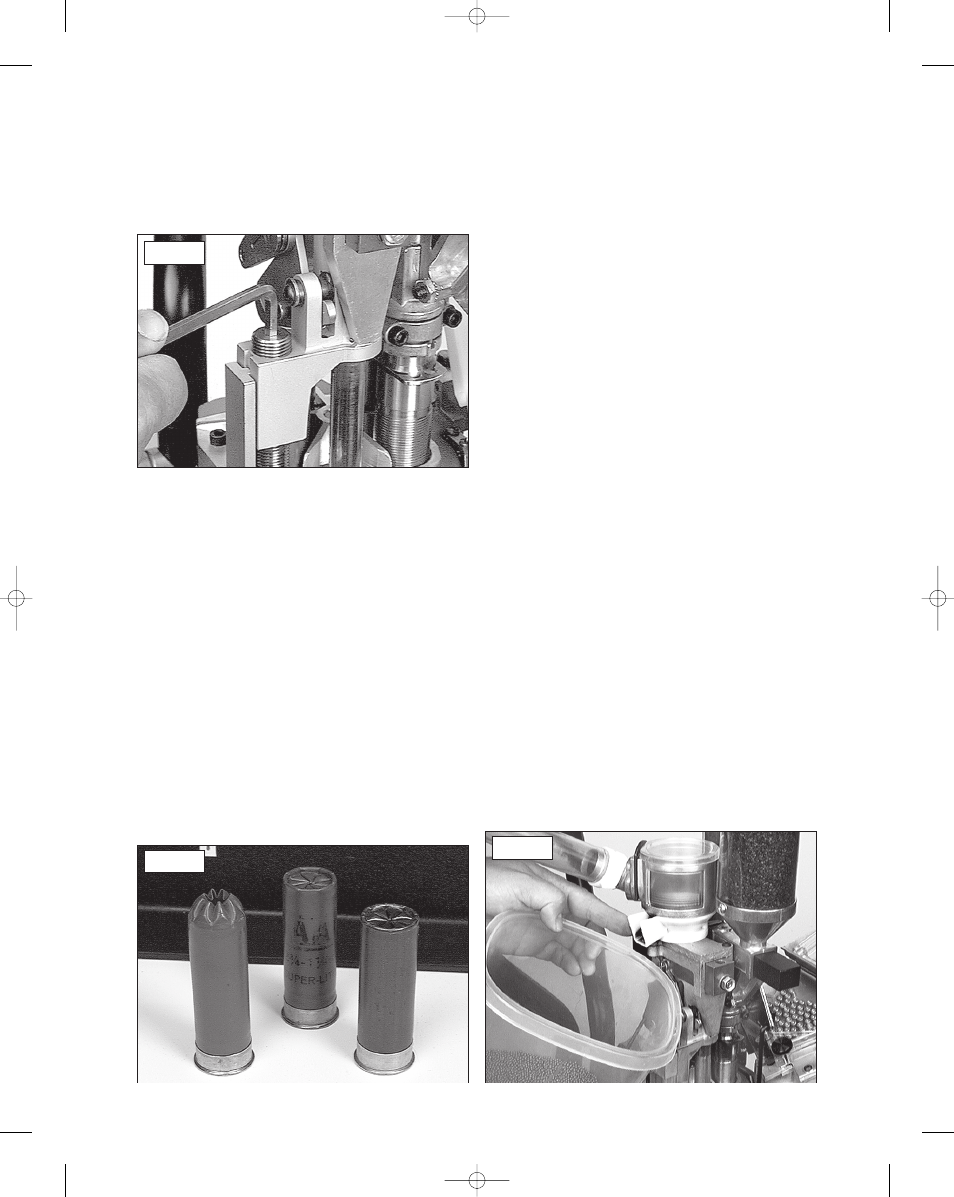

when it was built and adjusted at the factory. If you

have selected a wad that uses a lighter or heavier load

of shot, you’ll need to readjust the position of the shot

dispenser. Using a 5/32” Allen wrench, loosen the

two screws on the collar guide/clamp (#16737). Fig.

62 A 3/16” Allen wrench is used to rotate the body

collar adjustment screw (#10641).

When reloading with light shot load plastic wads

it may be necessary to adjust the shot dispenser

position. Rotate the body collar adjustment screw

(#10641) clockwise to raise the shot dispenser.

Tighten all the collar screws, then test the changes.

Fig. 63

When reloading with heavy shot load plastic wads

it may be necessary to adjust the shot dispenser

position. Rotate the body collar adjustment screw

(#10641) counterclockwise to lower the shot

dispenser. Tighten all the screws, then test the

changes.

5. Adjusting the starter crimp Die – This die has been

adjusted at the factory using Winchester AA hulls. If

you have another brand of hull you’d like to reload, it

may be necessary to readjust this die. Test run a hull

through the machine to decide if any changes are

needed.

What we like to see is a 60% closure of the top,

formed and folded. This is important so that station

five’s final crimp/seat can produce a uniform folded

crimp.

Fig. 64

We found that when we reloaded Remington hulls

and wads, we would need to adjust the starter crimp

die (#10640) down. The heavier walled Remington

hulls appear to be somewhat more resistant to being

formed and folded. Turn the starter crimp die

(#10640) down approximately one-half turn

clockwise as needed.

Reloading with Federal hulls and wads requires a

little readjusting as well. Raise the starter crimp die

(#10640) approximately one-half turn counter-

clockwise. This will help produce a uniform folded

crimp/seat.

Winchester hulls and Versatile wads loaded fine

and required little or no adjustment at all. Remington

hulls and Versatile wads also loaded fine. Remington

hulls and Figure 8 wads require adjustment. The stiffer

style Figure 8 wad needs to be compressed; do so by

lowering the wad seated depth 1 to 2 full turns (as

detailed under step 4 of Changes and Adjustments).

Also, reducing the shot charge weight may be

necessary when using this wad. Follow the above

changes with a readjustment of the starter crimp die

(#10640), turn the die down approximately one-half

turn clockwise as needed (as detailed under step 5 of

Changes and Adjustments).

6. Adjusting the final crimp Die – Two adjustments

are available here on the final crimp die. Example, if

some of the reloads you have just finished appear

shallow as shown, then turn the seat plug clockwise

(down), using 1/4 turn increments.

Or, you can turn the whole die clockwise (down)

using 1/4 turn increments. You will then see the next

reload with more taper on its end and the seated

depth will be deeper.

Another example relating to the final crimp die

adjustment when reloading different shotshells:

“When I have made some reloads, some of the

shotshells have buckled in the middle, but it doesn’t

happen all the time.” You will need to raise the whole

die by turning the assembly counterclockwise (up) at

least 1/4 to 1/2 a turn.

Removing the Shot from the Machine:

Fig. 63

Fig. 64

Fig. 65

31

SL 900, May 2007 5/21/07 11:51 AM Page 31