Dillon Precision SL 900 User Manual

Page 30

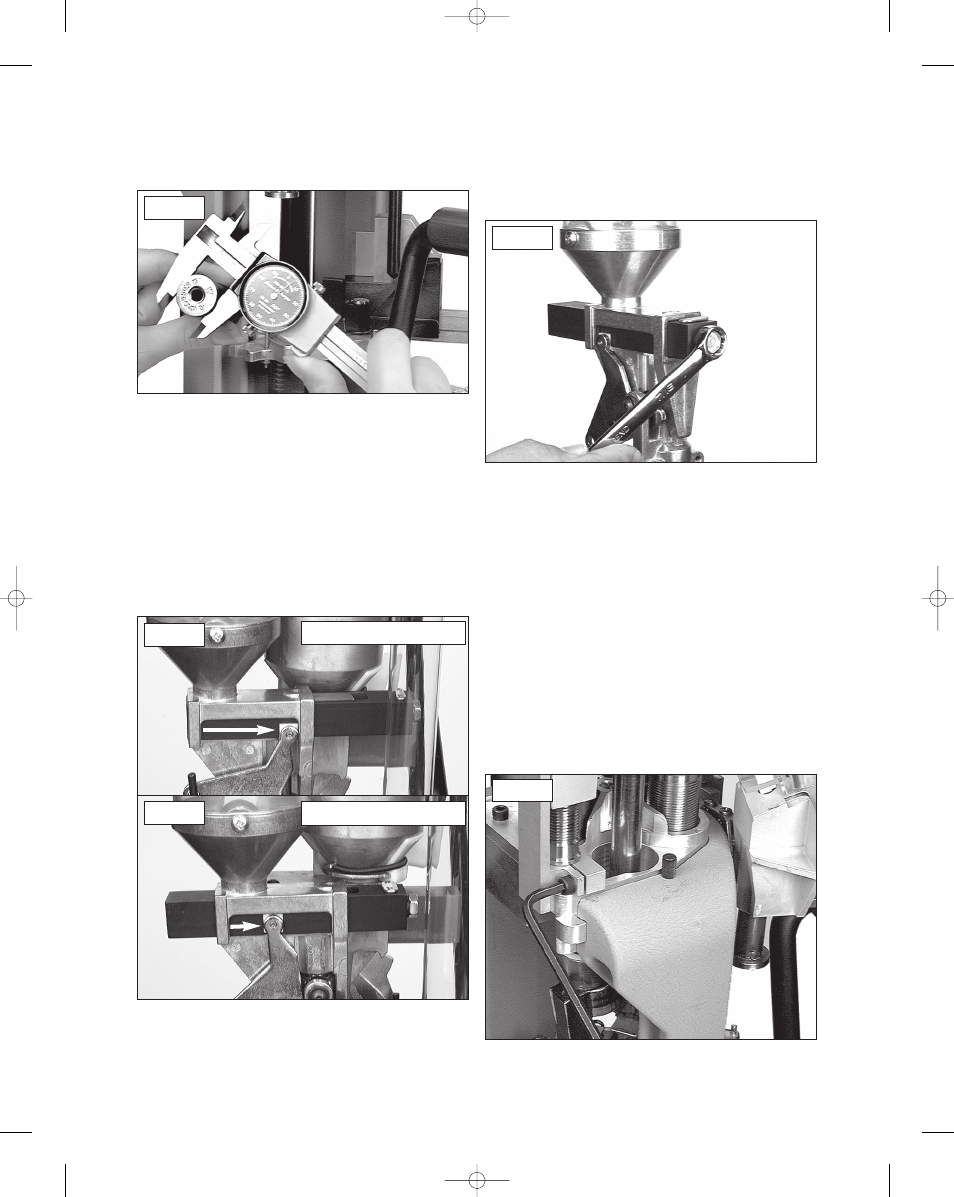

are needed when adjusting the 12 Ga. collet sizer die

(#16743). A 3/16” Allen wrench and a dial caliper.

Loosen the die lock bolt (#17351) located in the

bottom of the toolhead (#16667). Fig. 57

Using a fired hull, measure the diameter of the

brass base. Place the hull into the machine’s

shellplate at station one and resize the hull. Remove

the hull from the machine and again measure the

diameter. The brass base should be .804 diameter. Fig.

58 See page 17 for shotshell dimensions.

To make the brass base smaller, turn the die

clockwise using one-quarter turn increments. Using

another fired hull to test the new setting, resize the

hull in the machine. Again, measure the diameter of

the brass base. When you’re finished, tighten the die

lock bolt (#17351)

2. Powder Die/Funnel Adjustments – When a powder

charge is dropped into a hull, it is very important that

the bell crank also makes a complete stroke

simultaneously. Fig 59 Turning the powder die

(#16744) clockwise lowers the powder system and

increases the stroke of the bellcrank. Be careful not to

go down too far or you may crush a hull. Turning the

powder die (#16744) counterclockwise will raise the

powder system, reducing the amount of stroke the

bellcrank has. Fig. 60

3. Adjusting the Automatic Powder System Powder

Charge Weight – Place a hull at station two and cycle

the handle. Weigh the powder charge from the hull

and write that weight down. Using a 7/16” wrench,

rotate the bolt located on the end of the powder bar.

Fig. 61 Counterclockwise will reduce the powder

charge weight, adjust as needed. Helpful hint: operate

the powder bar a minimum of four times so you are

assured of a uniform powder charge, then weigh the

fifth charge.

4. Adjusting the Wad and Shot Station – Shot charge

weight adjustments: Weigh the shot charge from a

hull and write that weight down. Refer to your

loading manual to decide whether you need to

increase or decrease the shot charge weight. Using a

7/16” wrench, rotate the bolt on the shot bar (#16738)

clockwise to increase the weight or counterclockwise

to reduce the weight. Adjust as needed.

Adjusting the Plastic Wad Depth – A sample

plastic wad was included with your SL 900 machine

Fig. 61

Fig. 58

Fig. 59

Complete Stroke

Fig. 60

Incomplete Stroke

Fig. 62

30

SL 900, May 2007 5/21/07 11:51 AM Page 30