Chicago Gaming Medieval Madness Remake User Manual

Page 93

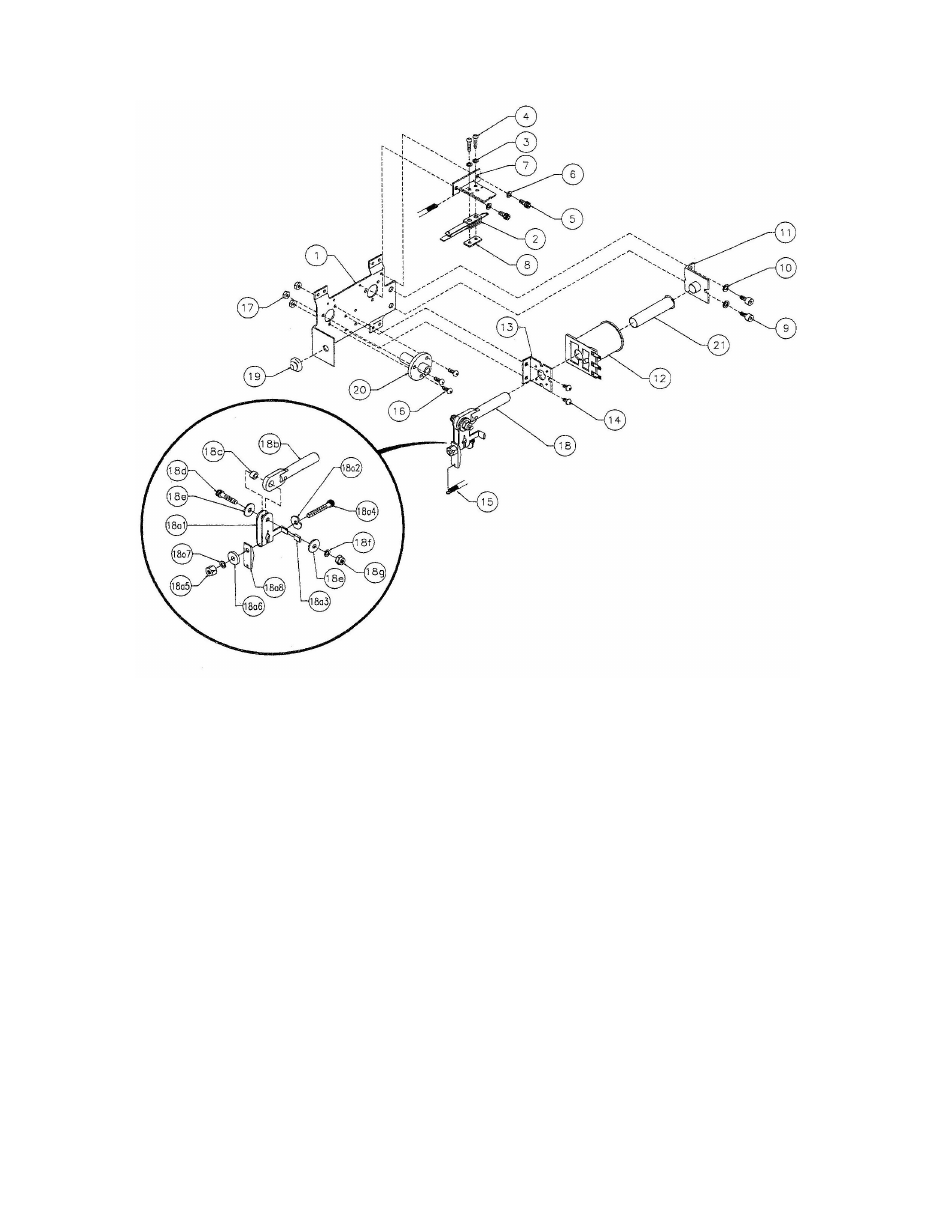

Item

Part Number

Description

18

A-15848-R

Crank Link Assembly, Right

a)

A-17050-R

Flipper Crank, Right

2.

4700-00107-01

Mod Crank Washer

3.

RM-23-06

Item

Part Number

Description

4.

4010-01066-20

Nut, 10-32 Hex.

1

B-13104-R

Flipper Base Assembly, Right.

6.

4700-00107-00

FW, 13/64 x 5/8 x 12ga.

2

SW-1A-194

Switch Assembly

7.

4701-00004-00

Lockwasher #10 Split

4

4105-01019-10

Sh. Metal Screw, #5 x 5/8"

b)

A-15847

Flipper Link Assembly

5

4008-01079-05

Mach. Screw, 8-32 x 5/16"

c)

02-4676

Link Spacer Bushing

6

4701-00003-00

Lock Washer #8 Split

d)

4010-01086-14

Cap Screw, 10-32 x 7/8"

7

01-9375

Switch Mounting Bracket

e)

4700-00023-00

Flat Washer, 5/8 x 13/64 x 16ga.

8

20-6516

Speednut, Tinnerman

f)

4701-00004-00

Lock Washer #10 Split

9

4010-01066-06

Cap Screw, 10-32 x 3/8"

g)

4410-01132-00

Nut 10-32 ESN

10

4701-00004-00

Lock Washer #10 Split

19

23-6577

Bumper Plug, 5/8"

11

A-12390

Flipper Stop Assembly

20

03-7568

Flipper Bushing

12

FL-11629

Flipper Coil, Blue

21

03-7066-5

Coil Tubing

13

01-7695-1

Solenoid Bracket

14

4006-01017 -04

Mach. Screw, 6-32 x 1/4"

Associated Parts:

15

10-364

Spring

23-6695

Flipper Ring

20-10110-5

Flipper Bat w/Shaft

PIN-A-15849R2

Flipper Assembly

RE

F

.

3

4701-00002-00

Lock Washer #6 Split

8.

01-9376

Spring Retainer Bracket

Flipper Crank Assembly, Right

1.

01-11764-R

(Not Shown)

16

FSM-063-PPH043C Mach. Screw, 6-32 x 7/16"

17

FNT-063-ESNA125 Nut 6-32 Nylock, 1/8" Tall

Flipper

Notes

:

1. Each Flipper Assembly is mounted beneath the playfield, in conjunction with the Plastic Flipper & Shaft, and Flipper Rubber on the upper side of the playfield,

2

. With the flipper, in the non-activated position, the E.O.S. Switch contacts must have

a

gap of .062 (±.015) inch. When flipper is activated switch must close.

3. Any adjustment of the E.O.S. switch must be made at

a

minimum distance of 0.25 inch from the switch body.

4

.

Longer blade of E.O.S, switch must be made straight. Gap adjustment is done by adjusting shorter blade.

5

. All moving elements of the assembly must operate freely without any evidence of binding.

6

. Apply Loctite

290 when reattaching screws to the Flipper Stop Assembly and the Solenoid Bracket

H.S. Tubing,

1/4"

MS, 10-32 x 1-

1/4"

5.

4410-01127-00

2-10