Using auxiliary wood facing, Constructing a featherboard – Delta N028314 User Manual

Page 26

26

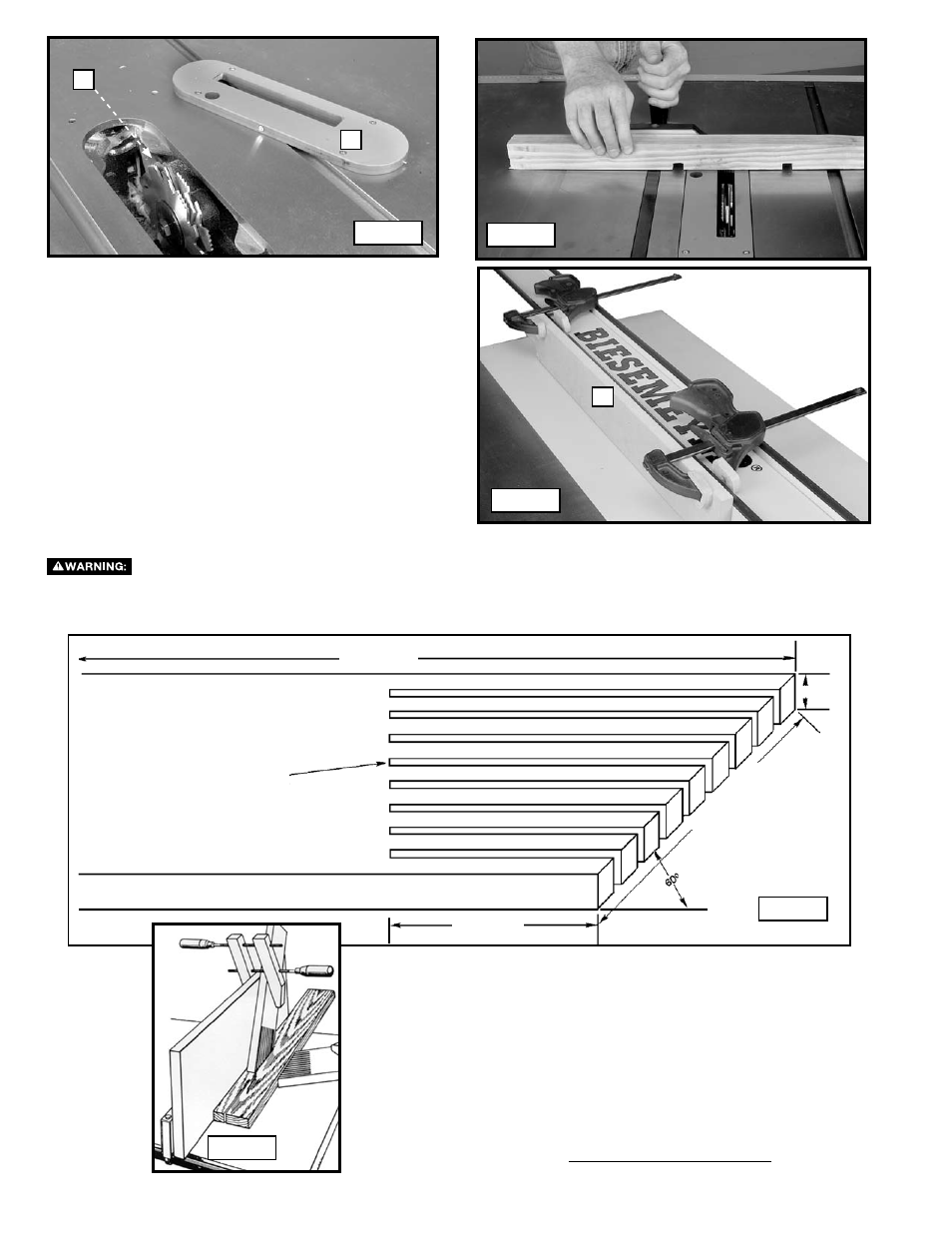

Fig. 65

Fig. 64

E

d

USINg AUXILIARY WOOd FACINg

Add a wood facing (A) Fig. 66 to one or both sides of the

rip fence when you perform special operations (moulding

cutterhead, etc.). Depending on the fence, attach the wood

facing or the fence either with wood screws through holes

drilled in the fence, or with two clamps. For most work, 3/4"

(19 mm) stock is suitable, although an occasional job may

require 1" (25.4 mm) facing.

Featherboards are used to keep the work in contact with

the fence and table (Fig. 68), and help prevent kickbacks.

Dimensions for making a typical featherboard are shown in

Fig. 67. Make your featherboard from a straight piece of wood

that is free of knots and cracks. Clamp the featherboard to the

fence and table so that the leading edge of the featherboard will

support the workpiece until the cut is complete. An 8" (203 mm)

high flat board can be clamped to the rip fence and the featherboard can be clamped to the 8" (203 mm) high board.

Use featherboards for all non-through-cutting operations where the guard and splitter assembly cannot be

used. Always replace the guard and splitter assembly when the non-through-cutting operation is complete. Make sure the

featherboard presses only on the portion of the workpiece in front of the blade.

Additional Information on table saw safety, including

a table saw safety video, is available from the

following:

POWER TOOL INSTITUTE

1300 Sumner Avenue

Cleveland, OH 44115-2851

www.powertoolinstitute.com

CONSTRUCTINg A FEATHERBOARd

A

Fig. 66

Kerf should be about

1/4" (6.4 mm)

24" (610 mm)

3/4" (19 mm)

4-1/2"

(114

mm)

5" (127 mm)

Fig. 67

Fig. 68