Operation, Operational controls and adjustments – Delta N028314 User Manual

Page 17

17

OPERATION

Make sure that the saw has been turned off before plugging cord into outlet. do not touch the plug’s

metal prongs when unplugging or plugging in the cord.

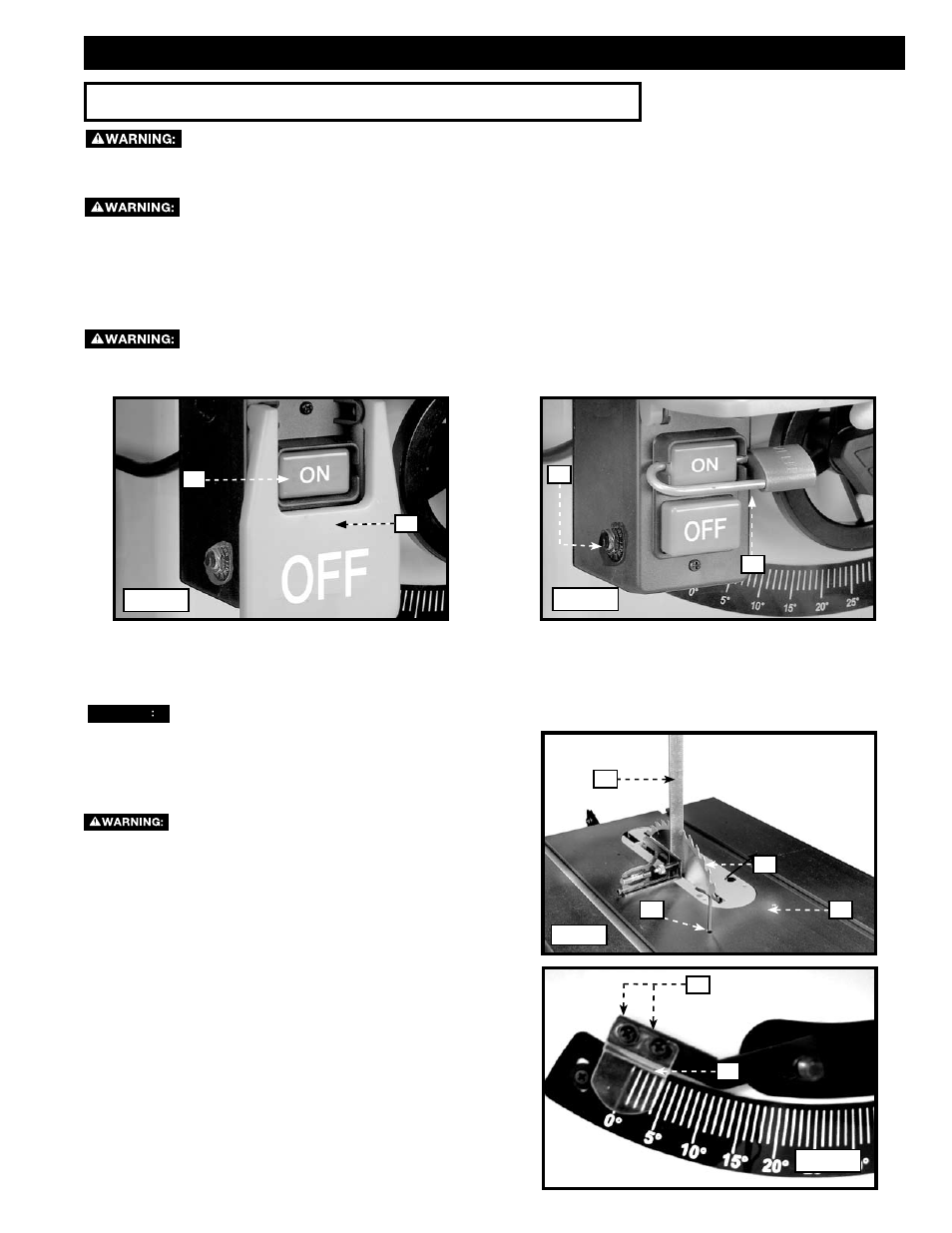

The on/off switch is located underneath the switch shield (A) Fig. 35. To turn the saw “ON”, press the green button (B) Fig.

35 below the shield. To turn the saw “OFF”, push the switch shield (A) Fig. 35.

LOCKINg THE SWITCH IN THE “OFF” POSITION

IMPORTANT: When the tool is not in use, the switch should be locked in the “OFF” position to prevent unauthorized use.

Use a padlock (B) Fig. 36 with a 3/16" diameter shackle.

In the event of a power outage (such as a breaker or fuse trip), always move the switch to the “OFF”

position until the main power is restored.

OPERATIONAL CONTROLS ANd AdJUSTMENTS

To reduce the risk of personal injury, turn unit off and disconnect it from power source before installing

and removing accessories, before adjusting or when making repairs. An accidental start-up can cause injury.

STARTINg ANd STOPPINg THE SAW

A

Fig. 35

Fig. 36

B

OVERLOAd PROTECTION

The saw is equipped with a reset button (A) Fig. 36. If the motor shuts off or fails to start due to overloading (cutting stock

too fast, using a dull blade, using the saw beyond its capacity, etc.), or low voltage, turn the saw off by pushing the switch

shield (A) Fig. 35. Let the motor cool three to five minutes and push the reset button (A) Fig. 36. Start the motor.

NOTICE

AVIS

AVISO

fr

sp

If the motor continually shuts off due to overloading, contact a qualified electrician.

A

B

AdJUSTINg 90° ANd 45° POSITIVE STOPS

Your saw is equipped with positive stops that will quickly

and accurately position the saw blade at 90° and 45° to the

table. To check and adjust the positive stops:

disconnect the machine from the power

source.

Fig. 37

Fig. 38

A

B

F

C

E

d

1. Raise the saw blade to its highest position.

2. Set the blade at 90° to the table by turning the blade-

tilting handwheel counterclockwise as far as it will go.

3. Use a combination square (A) Fig. 37 to see if the blade

is 90° to the table surface.

4. If not, turn the handwheel one turn clockwise. Loosen the

set screw (B) Fig. 37 with a 5/32" hex wrench. Turn the

handwheel until the blade is at 90° to the table. Tighten

the set screw (F) until it bottoms.

5. Loosen the screws (E) Fig. 38, adjust the hairline indicator

(D) to point to the 0° mark on the scale, and tighten the

screws (E).

6. Turn the handwheel clockwise as far as it will go and use

a combination square to see if the blade is at 45° to the

table.

7. If not, turn the handwheel one turn counterclockwise.

Loosen the set screw (F) Fig. 37. Turn the handwheel until

the blade is 45° to the table. Tighten the set screw (F) until

it bottoms.