Delta N028314 User Manual

Page 23

23

3/4" (19 mm) plywood

Width of saw + 2" (51 mm)

3-5/8"

(92.1 mm)

TOP VIEW

4"

(101 mm)

1"

(25.4 mm)

3/8" (9.5 mm)

1"

(25.4 mm)

2-1/4"

(57.2 mm)

2" x 4"

(51 mm x 101 mm)

block

2" x 4"

(51 mm x 101 mm)

block

6"

(152 mm)

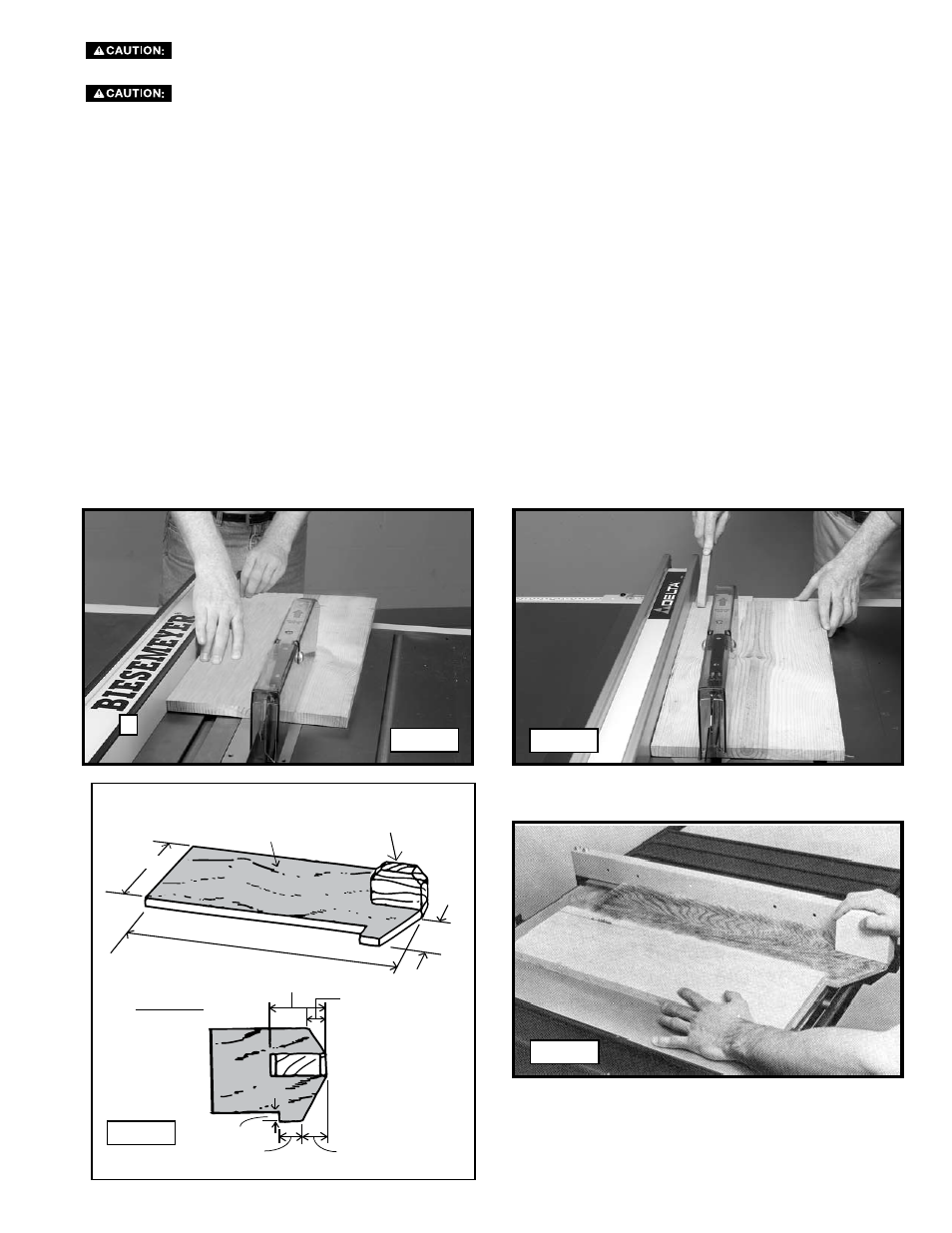

The workpiece must have a straight edge against the fence and must not be warped, twisted or bowed.

Keep both hands away from the blade and away from the path of the blade. See proper hand position in Fig. 52.

Never push or hold onto the free or cut off side of the workpiece.

1. Before starting the cut, raise the blade so that it is about 1/8" (3.2 mm) higher than the top of the workpiece. Start the

motor and advance the work, holding it down and against the fence.

NEVER stand in the line of the saw cut when ripping.

When the rip width is 6" or wider, hold the work with both hands and push it along the fence and into the saw blade (Fig.

52). Feed force when ripping should always be applied between the saw blade and the fence. Never pull the workpiece

from the back of the saw. The work should then be fed through the saw blade with the right hand. Keep pressure on the

workpiece against the fence and down on the saw table. Ensure that you have adequate outfeed support for the workpiece

and

KEEP YOUR HANdS AWAY FROM THE SAW BLAdE.

2. When the workpiece is past the blade, the work will either stay on the table or tilt up slightly and be caught by the end

of the guard. Alternately, the feed will continue to the end of the table, and be lifted and brought along the outside edge

of the fence. When ripping boards longer than 3' (914.4 mm), use a work support at the rear of the saw to keep the

workpiece from falling off the saw table.

3. If the size or shape of the workpiece would cause your hands to be within 6" (152.4 mm) of the saw blade, use a push

stick to complete the cut (Fig. 53) The push stick can easily be made from scrap material as explained in the section

Constructing A Push Stick.

4. Ripping narrow pieces can be dangerous. If possible, rip the narrow piece from the larger piece. If the workpiece is short

enough, use a pushboard. (A pushboard can be constructed as shown in Fig. 54 and used as shown in Fig. 55.)

NOTE: In Fig. 55, the guard and splitter have been removed for clarity. Use the guard and splitter when ripping.

5. For longer pieces, use one or more pushsticks to avoid placing your hands between the fence and the blade. Always use

care to avoid binding narrow strips between the anti-kickback pawls and the splitter.

NOTE: Some special operations (moulding cutterhead, etc.) require the addition of an auxiliary wood facing to the fence, as

explained in the section

Using Auxiliary Wood Facing, and use of a push stick.

Fig. 52

Fig. 53

Fig. 54

Fig. 55

A