Delta 50-257 User Manual

Safety instructions, Contents (fig. 1), Introduction

iF YoU HAVE ANY QUESTioNS oR

CoMMENTS ABoUT THiS oR ANY DELTA

MACHiNERY ACCESSoRY, CALL US ToLL

FREE AT 800-223-7278.

SAFETY iNSTRUCTioNS

To reduce the risk of injury, read

the tool instruction manual before using any

accessory. Failure to heed these warnings

may result in personal injury and serious

damage to the tool and the accessory. When

servicing this tool, use only identical replace-

ment parts.

To reduce the risk of injury, turn

tool off and disconnect it from power source

before installing and removing accessories,

before adjusting or when making repairs. An

accidental start-up can cause injury.

The 50-257 or 50-2000 Mobile

Base has been reviewed and approved for

use only with left tilt DELTA Unisaws built on

or after March 2009. The date code is found

on your Unisaw in this format (2009 X-39).

(The “X” denotes the week of the year it was

built.)

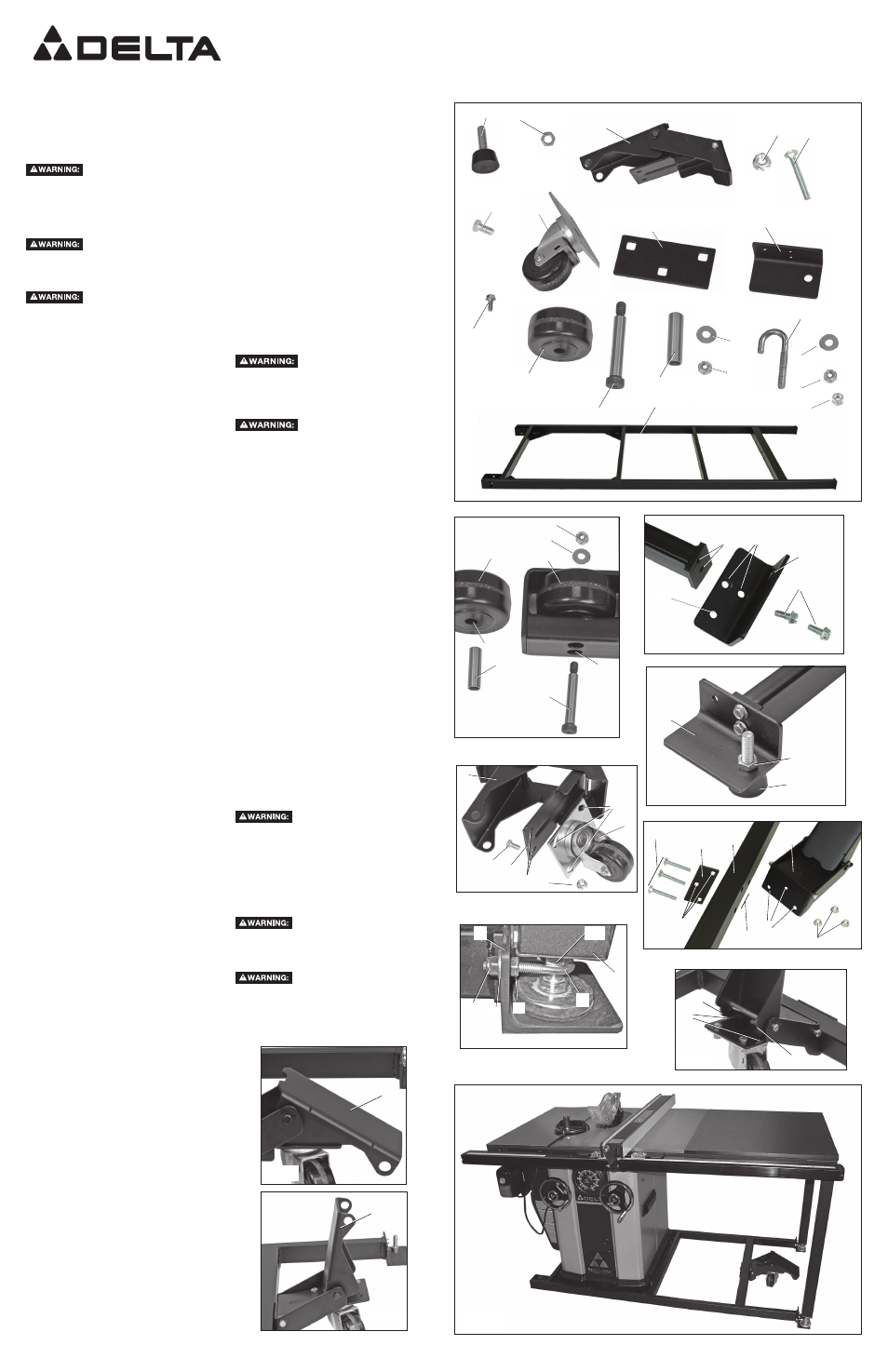

CoNTENTS (FiG. 1)

A. (2) Rubber feet

B. (2) 1/2-13 Hex nuts

C. (1) Pedal assembly

D. (7) 3/8-16 Hex head serrated flange nuts

E. (3) 3/8-16 x 3" (76.2 mm) Carriage bolt

F.

(4) 3/8-16 x 3/4" (19 mm) Hex head screws

G. (1) 3" (76.2 mm) Swivel Caster

H. (1) Pivot bracket

I.

(2) Angle foot bracket

J. (4) 5/16-18 x 3/4" (19 mm) hex head

serrated flange bolt

K. (2) Wheels

L. (2) 2" (50.8 mm) Shoulder screws with

3/8” (9.5 mm) shoulder; threads are

5/16-18)

M. (2) Sleeves for shoulder screws

N. (2) 5/16" Flat washers

O. (2) 5/16-18 Nylon lock nuts

P. (2) 1/4-20 x 2-5/16" (58.7 mm) J bolts

Q. (2) 1/4" Flat washers

R. (2) 1/4-20 Nylon lock nuts

S. (2) 1/4-20 Hex nuts

T. Saw base frame

iNTRoDUCTioN

This mobile base features welded, heavy-gauge

steel supports with a bolt-on foot lever, a single

swivel caster, and two sturdy wheels. Rubber

feet positioned opposite the fixed wheels assure

stable contact when the base is lowered into

the stationary position. The convenient foot

lever raises and lowers the base for ease in

moving and positioning the machine, and allows

the machine to be moved aside for cleaning

purposes.

ASSEMBLY

NoTE: Do not place Unisaw on the mobile base

until the base is fully assembled.

NoTE: The saw frame (S) Fig. 1 comes fully

assembled. User must attach fixed wheels, angle

brackets, rubber feet, swivel caster, foot pedal

assembly and J bolt anchors.

ASSEMBLiNG FiXED WHEELS iN SAW BASE

END

1. Place the sleeve (M) Fig. 2 into hole in fixed

wheel (K) and place wheel inside the saw

base frame as shown.

2. Slide a 2" (50.8 mm) shoulder screw (L)

Fig. 2 through bottom hole (U) at saw base

frame end and then through the hole (V) in

the wheel (K) and out the bottom hole in the

other side of saw base frame bracket.

3. Place a 5/16 flat washer (N) Fig. 2 on the

threads of the shoulder screw and tighten

a 5/16-18 Nylon lock nut (O) onto the end

of the shoulder screw (L). To tighten, hold

shoulder screw (L) with a 3/16 hex wrench

and tighten Nylon lock nut with 1/2" socket

wrench.

4. Repeat these steps for other wheel.

ASSEMBLiNG ANGLE BRACKETS AND

RUBBER FEET

1. Line up two holes (W) Fig. 3 in angle bracket

(I) with two holes (X) in saw frame extension

end. Insert two 5/16-18 x 3/4” (19 mm) hex

head serrated flange bolts (J) through holes

(W) in the bracket and into the tapped holes

(X) of the saw frame extension end. Tighten

these down with 1/2" socket wrench.

2. Insert rubber foot (A) Fig. 4 up through hole

in angle bracket (I) as shown.

3. Attach 1/2-13 jam nut (B) Fig. 4 to post of

rubber foot (A) and tighten down with 3/4"

wrench.

4. Repeat all steps for other angle bracket and

rubber foot.

ASSEMBLiNG SWiVEL CASTER To PEDAL

ASSEMBLY

1. Line up four holes (three shown at (Y) Fig. 5)

in the caster (G) with four holes (two shown

at (Z)) in the foot pedal bracket (AA) on the

foot pedal assembly (C).

2. Insert 3/8-16 x 3/4” (19 mm) hex head screw

(F) Fig. 5 down through holes in the foot

pedal bracket (AA) and then the caster (G).

3. Place 3/8-16 hex head serrated flange

nut (D) Fig. 5 on screw (F) underneath and

tighten with a 9/16” wrench.

50-257 or 50-2000 MoBiLE BASE FoR DELTA UNiSAW

A28939 - 8-25-09 Rev. 1

W

X

I

J

A

FIG. 3

FIG. 4

I

B

FIG. 5

Y

Z

AA

C

F

D

G

E

H

CC

BB

D

FIG. 6

C

T

DD

FF

FIG. 2

M

K

O

N

L

U

K

V

4. Repeat with three more screws (F) and nuts

(D) for the remaining three holes in caster (G)

and foot pedal bracket (AA).

ASSEMBLiNG PEDAL ASSEMBLY

To SAW BASE FRAME

1. Line up holes (BB) Fig. 6 in the pedal

assembly (C) with holes (CC) on side of saw

base frame (T) opposite the fixed wheels (K)

Fig. 1.

2. Line up holes (DD) Fig. 6 in pivot bracket (H)

with holes (not shown) on the opposite side

of the saw base frame (T) from holes (CC).

3. Insert 3/8-16 x 3" (76.2 mm) carriage bolt (E)

Fig. 6 through hole in pivot bracket (H), in saw

base frame (T) and in pedal assembly (C).

4. Fasten carriage bolt (E) Fig. 6 with a 3/8-16

hex head serrated flange nut (D) against the

inside of the pedal assembly (C), using 9/16

wrench.

5. Repeat for other two carriage bolts (E) Fig. 6

and serrated flange nuts (D).

PLACiNG SAW AND EXTENSioN TABLE

oN MoBiLE BASE

RiSK oF iNJURY FRoM

LiFTiNG. Serious injury can result from

attempting to lift too heavy an object. The

machine can weigh more than 550 pounds and

is too heavy to be lifted by one person. Obtain

assistance from others before lifting.

PiNCH HAZARD. Be sure not

to place toes or fingers underneath the base

of the Unisaw while moving. Lift the saw from

underneath the table, before saw is assembled,

or from underneath the wings and extension

table after assembly.

Carefully lift saw and extension table onto mobile

base. Make sure extension legs (EE) Fig. 7 rest

on angle brackets (I) as shown.

ASSEMBLiNG J BoLTS To ANGLE BRACKETS

The J bolts are required to join the base to the

extension table legs and will keep the table legs

resting properly on the base while moving the

base.

1. Place 1/4-20 hex nut (S) Fig. 7 on J-bolt

(P) and screw it on until it bottoms out on

threads.

2. Make sure J bolt (P) Fig. 7 is around leveling

screw (GG) on extension leg (EE) as shown

in Fig. 7.

3. Insert J bolt (P) Fig. 1 and Fig. 7 through hole

(FF) Fig. 3 in angle bracket (I).

4. Adjust hex nut (S) until it touches the angle

bracket (I).

5. Place a 1/4" flat washer (Q) Fig. 7 on J bolt

(P) and fasten it to angle bracket (I) using a

1/4-20 Nylon lock nut (R). Tighten nut using

7/16" wrench.

6. Repeat for J bolt (P) on the other angle

bracket (I).

oPERATiNG MoBiLE BASE

NoTE: Before operating the base, apply grease

to the cams (HH) Fig. 8 and where they meet the

foot pedal bracket (AA).

When the foot pedal (II) is pushed down as

shown in Figure 9, the base is mobile.

To reduce the risk of injury, do

not operate the saw when the base is mobile

(when the foot pedal (ii) is pushed down as

shown in Fig. 9).

When the foot pedal (II) is raised (as shown in

Figure 10), the base is lowered down to the floor

so it does not move. If the saw is not level in this

position, you can adjust the two extension table

legs (EE) Fig. 7 on your Unisaw using the leveling

screw (GG).

To reduce the risk of injury,

when lifting on foot pedal (II) Fig. 9 to lower the

saw down and make it stationary, be careful as

the pedal swings back with force. Stay clear of

the motion of this pedal.

To reduce the risk of injury,

make sure that your feet are clear of the base

before lowering the unit.

Figure 11 shows a Unisaw correctly attached to

the mobile base.

HH

HH

AA

FIG. 8

II

FIG. 9

FIG. 10

II

FIG. 11

A

C

H

Q

P

R

D

B

E

F

G

I

J

K

L

M

N

O

T

FIG. 1

S

FIG. 7

EE

R

Q

P

GG

P

S