V. gas supply, V. gas supply caution, Figure 2-12 - flexible gas hose installation – Blodgett S1820G User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

V. GAS SUPPLY

CAUTION

DURING PRESSURETESTiNGNOTETHEFOLLOWING:

1. The oven and its individual shutoff valve must be discon

nected from the gas supply piping system during any

pressure testing of that system attest pressure in excess

of 1/2 psi (3.45 kPa).

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve dur

ing any pressure testing of the gas supply piping system

at test pressure equal to or less than 1/2 psi (3.45 kPa).

3.

If incoming pressure is over 14" W.C. (35mbar), a

separate regulator MUST be installed in the line BEFORE

the Individual shutoff valve for the oven.

WARNlNG:To prevent damage to the control valve regu

lator during initiai turn- on of gaSj it is very Important to

open the manual shutoffvalve very slowly.

After the initial gas tum-on, the manual shutoff valve must

remain open except during pressure testing as outlined in the

above steps or when necessary during service maintenance.

A Gas Utility Rough-ln Recommendations

The following gas system specifications are STRONGLY

RECOMMENDED.

Deviating

from

these

recommendations

may affect the baking performance of the oven.

Gas Meter - 650 cfh (307^/min) meter

Gas Line

•

DEDICATED LINE from the gas meter to the oven

•

1-1/2" (50.8mm) pipe for natural gas

•

1-1/2" (38.1mm) pipe for propane

•

Maximum length: 200'(61m). Each 90“ elbow equals 7'

(2.13m) of pipe,

B. Gas Conversion

Where permitted by local and national codes, it is possible to

convert ovens from natural to propane gas, or from propane to

natural gas. Use the appropriate Middleby Gas Conversion Kit

for the specific oven model.

CAUTION:

The terms of the oven’s warranty require all start

ups, conversions and service work to be per

formed by a Middleby Authorized Service Agent

C. PS536 Propane Conversion

Two items have to be changed, to change the oven to LP;

1.

Replace main orifices.

2.

Adjust main gas regulator per instructions below.

Disconnect the manifold union closest to the main burner, and

remove the manifold assembly (four screws). Slide out the

manifold assembly (leaving the ignition and sense wires con

nected). Replace the main orifices.

Repiace the main orifices on the manifold assemblies with the LP

units, and repiace the manifoid assembly. Reconnect the union.

D. Adjusting the Maximum Pressure Setting

1. Disconnect pressure feedback connection (if appcable).

2.

Connect a suitable pressure gauge to pipe line or to

outlet pressure tap of gas control concerned, to mea

sure burner pressure (measuring point must be as

near to burner as possible).

3.

Make sure that the appliance is in operation and the

Moduplus® coil is energized with maximum current.

4.

if maximum rate pressure needs adjustment, use an 8

mm wrench to turn adjustment screw for maximum pres

sure setting (ciockwise to increase or counter-clockwise

to decrease pressure), until the desired maximum outlet

pressure is obtained.

5.

Disconnect electrical connection of the Moduplus®.

6.

Check minimum pressure setting and readjust if neces

sary. (See Adjusting Minimum Pressure Setting for

proper adjusting procedure.)

7.

Reconnect pressure feedback connection (if appcable).

8.

if minimum and maximum pressures are set, wire the

Moduplus® in circuit.

9.

Close pressure tap screw.

E Adjusting the Minimum Pressure Setting

1.

Disconnect pressure feedback connection (if appcable).

2.

Connect a suitable pressure gauge to pipe tine or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

Disconnect electrical connection of the Modupius®,

Energize operator, set control in operation and wait until

an outlet pressure is recorded on pressure gauge.

5. if minimum rate pressure needs adjustment, use an 8

mm wrench to turn adjustment screw for minimum

pressure setting (clockwise to increase or counter

clockwise to decrease pressure), until the desired mini

mum outlet pressure is obtained.

Check if main burner lights easily and reliable at mini

mum pressure.

Reconnect pressure feedback connection (if appcable).

Close pressure tap screw.

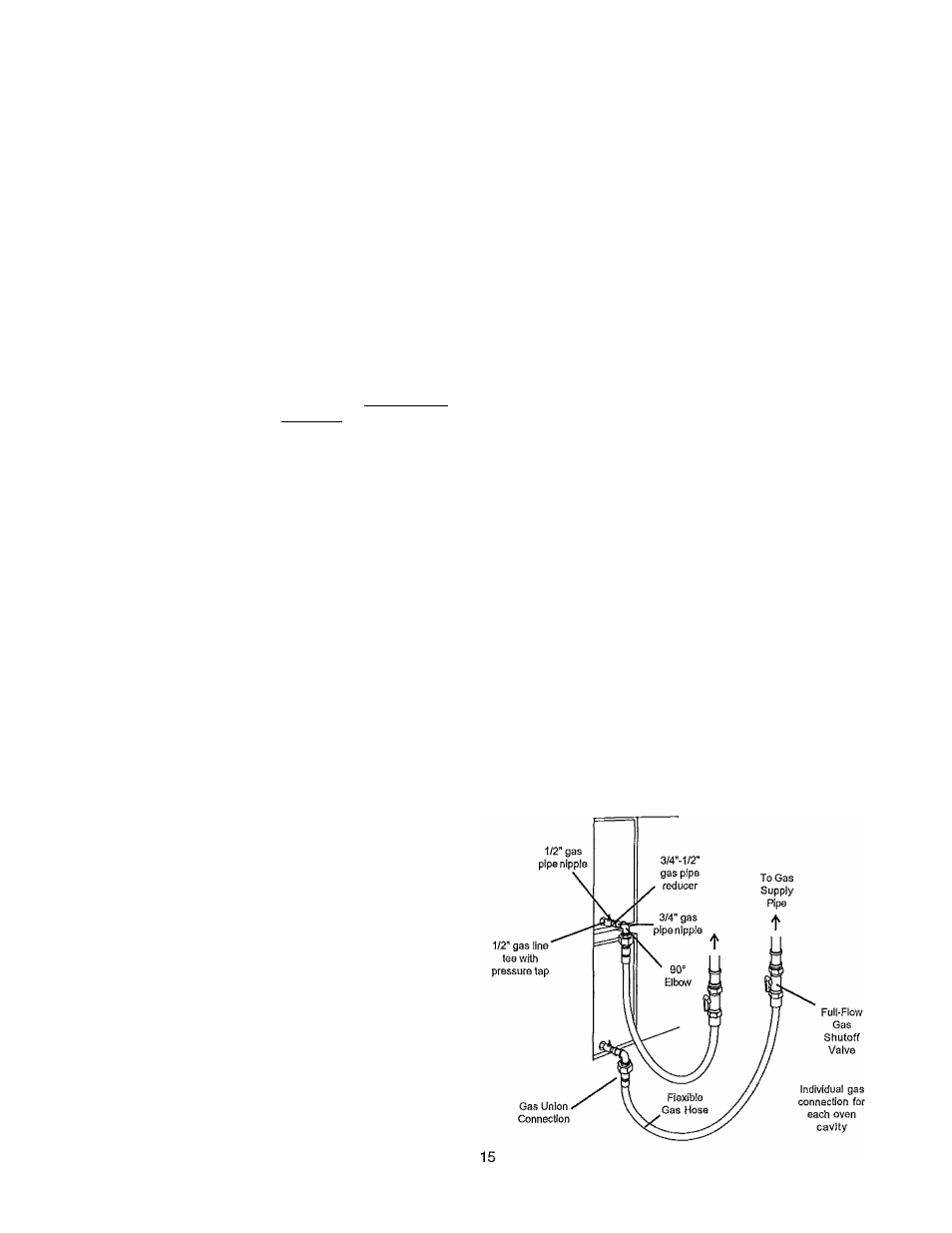

Figure 2-12 - Flexible Gas Hose Installation

SECTION 2

INSTALLATION

3.

4.

6

.

7.

8

.