Forming a thread shank – SINGER 1050 User Manual

Page 74

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

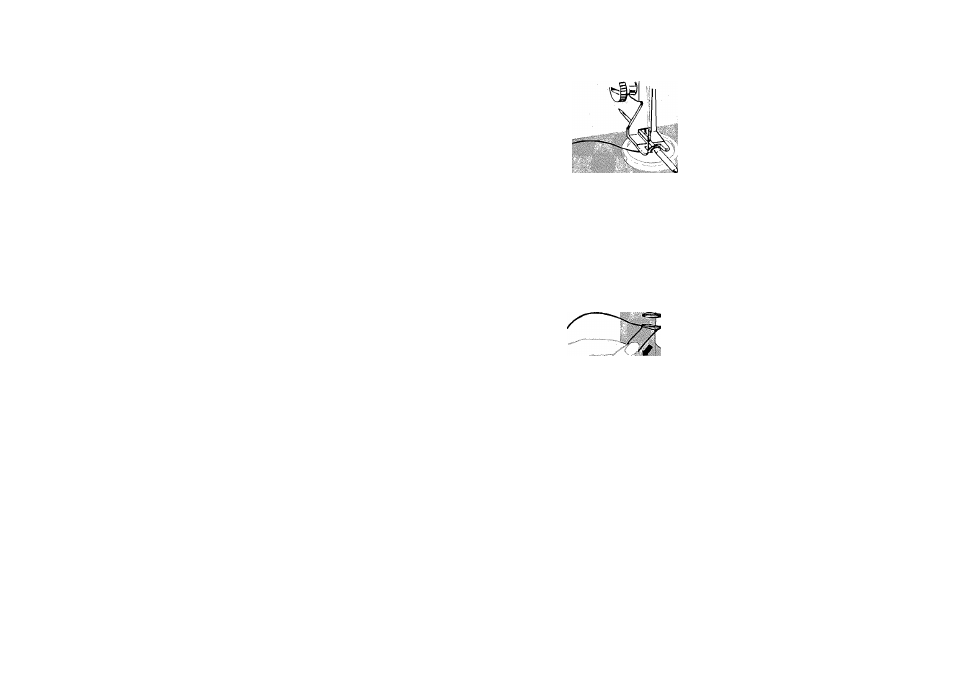

Forming a Thread Shank

Buttons sewn on coats and jackets should have a thread

shank to make them stand away from the fabric. A thread

shank is formed by sewing over the blade of a regular machine

needle.

Position needle, garment and button as described on

previous page.

Place needle in groove of foot so that point enters hole in

foot first, as shown. The further in you push needie, the

ionger the shank wili be.

Foliow procedure on previous page for button sewing.

After stitching, remove needle from groove of button foot,

remove work from machine, and cut threads about 15 cm

(6 inches) from fabric.

Pull upper thread ends to back of button. Form a firm

shank between button and fabric by winding threads tightly

around attaching stitches, and tie thread ends securely.

10 B

73

- 401A (116 pages)

- Simple 3116 (94 pages)

- 1507 (88 pages)

- 1507WC (88 pages)

- 112W140 (32 pages)

- 147-2 (30 pages)

- 114-33 (43 pages)

- 119-3 (23 pages)

- 14K1 (10 pages)

- 147-104 (34 pages)

- 116-1 (20 pages)

- 115-2 (38 pages)

- 14U286 (40 pages)

- 14U286B (21 pages)

- 114-4 (29 pages)

- 142W25 (10 pages)

- 147-81 (28 pages)

- 118 (16 pages)

- 136W105 (22 pages)

- 114-41 (20 pages)

- 147-4 (28 pages)

- 105-3 (30 pages)

- 1027 (36 pages)

- 147-26 (37 pages)

- 12W208 (25 pages)

- 128-4 (25 pages)

- 109-320 (14 pages)

- CP17 (47 pages)

- 147-6 (56 pages)

- 132B26 (9 pages)

- 114-2 (36 pages)

- 1371A3 (86 pages)

- 14CG754 (53 pages)

- 147-50 (39 pages)

- 14T967DC (3 pages)

- 109-520 (13 pages)

- 14SH654 ULTRALOCK (48 pages)

- 147-86 (30 pages)

- 105-20 (23 pages)

- W303 (13 pages)

- 147-38 (53 pages)

- 114-22 (45 pages)

- 1375A1 (33 pages)

- 107-2 (31 pages)

- 1200A (4 pages)