A caution – Carrier 38E User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Tl

Т2

3

SEC

OPERATING

TIME

5MIN-

BLK DENOTES CLOSED CONTACTS

TIME GUARD II SEQUENCE CHART

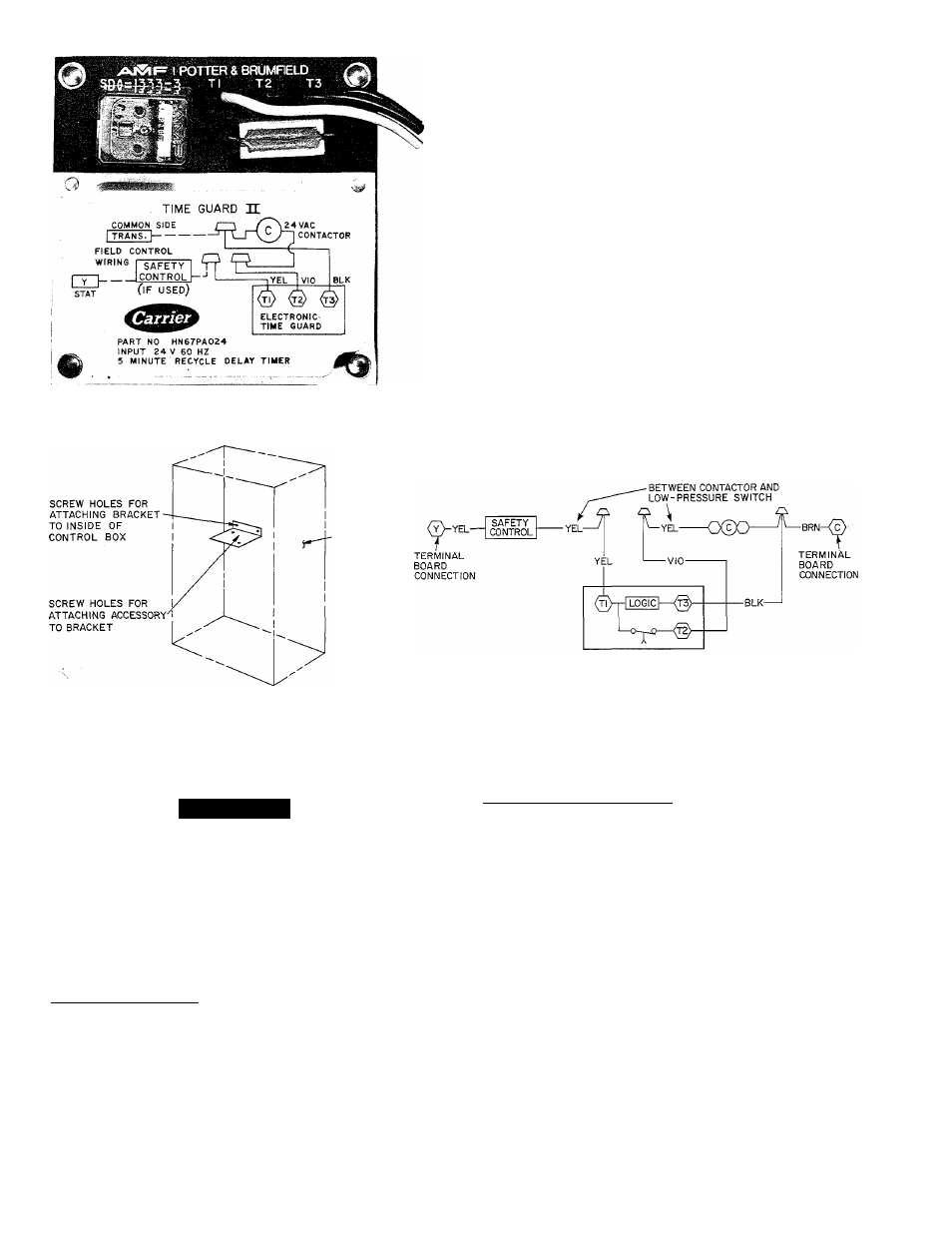

ACCESSORY TIME GUARD II DEVICE

CUT YELLOW WIRE

-CONTROL

BOX

MOUNTING ACCESSORY TIME GUARD II

ON MODEL 38QH,QS,QN

NOTE: When accessory Time Guard II is used with accessory Service Sentry control on

38QH,QN,QS units, refer to wiring instructions packed with Service Sentry control.

TIME GUARD II CONTROL WIRING

CONNECTIONS FOR 38QH,QN,QS UNITS

Fig. 8 — Solid-State Time Guard II Description

A

CAUTION

Wear safety glasses and gloves when working with

refrigerants. Apply heat with a torch to solder joint

and remove switch. Wear safety glasses when using

torch. Have quenching cloth available. Oil vapor in

line may ignite when switch is removed.

Braze in

1

/ 4-in. flare fitting and screw on replacement

pressure switch. Wear safety glasses, observe all safety

precautions.

High-Pressure Switch — Located on discharge line,

protects against high discharge pressures caused by such

events as overcharge, condenser fan motor failure, system

restriction, etc. It opens on pressure rise at about 425 psi.

If system pressures go above this setting during abnormal

condition, switch opens. Do not attempt to simulate

these system abnormalities, as high pressures pose a

serious safety hazard. High-pressure switch is also

checked with an ohmmeter similar to checking low-

pressure switch. If system pressure is below 425 psi, switch

shows continuity. It is replaced in same manner as low-

pressure switch. Observe all safety precautions.

Liquid Line Pressure Switch — Located on liquid line,

used in heat pump only. Function is similar to con

ventional low-pressure switch. Because heat pumps

experience very low suction pressures during normal

system operation, a conventional low-pressure switch

cannot be installed on suction line. Switch is installed

in liquid line instead and acts as loss-of-charge protector.

It operates identically to low-pressure switch except it

opens at 5 psi. Troubleshooting and removing this switch

is identical to procedures used on other switches. Observe

same safety precautions.

DEFROST THERMOSTATS — Defrost thermostat

signals heat pump that conditions are right for defrost or

that conditions have changed to terminate defrost. It is a

thermally actuated switch clamped to liquid line to sense

its temperature. Normal temperature range is: closed at

27 - 5 F, open at 80 ± 5 F.

Since defrost thermostat is the heart of the defrost

system, its troubleshooting procedure is described below.

PRINTED-CIRCUIT CONTROL BOARD — Solid-

state defrost control used on 38QH,QN,QS heat pumps

replaces electro-mechanical timer and defrost relay found

on previous Carrier Chronotemp^“ defrost systems. De

frost control board can be set to check need for defrost